Hey Dad,

Just read through this string w/pleasure. So so cool what you are

doing with your son! And you aren't making the mistake of just

handing it to him on a silver platter:

So my son went out and got himself a job at 15, saved up a few paychecks, and went and bought...

So listen, I've also got a roller-cam 383ci SBC on the engine stand,

and it will also end up with a manual tranny behind it. (Helping an

old friend put together a sleeper to help stave off boredom once

he crosses the finish line into retirement. :0)

Given this, I find the specifics of your build very interesting. And

before I go further, in the past I've found that with a little effort

a mongrel motor that was put together by cleaning off all the

shelves in the shop can be like the perfect stew that was

created by cleaning out the fridge. It can be astounding -- it is

the nature of the universe that sometimes when we try easier

we get the best results of all!

****

Alright. Since only a relative handful of us still put stickshifts

behind fresh motors, a few small details can cause real grief

once we try to stuff the powerplant in the engine bay w/no joy.

Or worse, it goes together, only to vibrate the entire time you

drive it. :0( Without further ado, here goes:

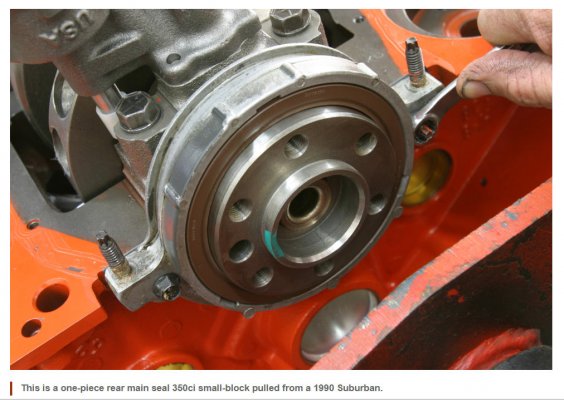

Clear, concise explanation of difference between '55-'85 SBC cranks w/2-piece oil seals vis-a-vis SBC '86+ cranks w/1-piece seals

You must be registered for see images attach

(credit: thirdgen.org -- follow this (

link) & refer to post #7)

NOTE: I can tell from your approach that this isn't your 1st rodeo,

so when you read the following I'm just trying to be precise about

the parts combo, not infer that you need a refresher on any of this. (!)

In post #25 you make mention of a "tbi roller block". OK, so that's

a 1-piece rear main seal design. So far so good. Now if you were

installing a stock 3.48" stroke 1-piece seal Chevy crank, the $80 flywheel

you mentioned in post #22 gets bolted on, the clutch/pressure

plate installs after that, and away you go. I get that.

But for this motor's recipe you have a 3.75" stroker crank.

(+ 5.7" rods, nice 2-eyebrow pistons to match, etc)

Q1: Is this aftermarket crank balanced

the same as the

3.48" stock crank it's replacing? (Ie: The flywheel that works

behind the stock 3.48" crank will

also work behind the aftermarket

3.75" crank? If so, cool beans.

IF on the other hand it has the same (lack of total) counterbalance

weight as the old stock 3.75" (400ci) Chevy cranks, then now

do we have to go down the externally-balanced 400ci flywheel path?

Do they even make those to bolt up to the flange on a 1-pc rear

main seal crank?

Q2: Using the casting part number seen in your photo (#

93433010N)

I poked around a little, and came up with this amazon listing showing a

near-identical new flywheel for sale. Please go look at the face of

that flywheel closely before looking at the pic below: (

Amazon link)

Is this part of a previous motor's balance job? Or is it just factory balancing to bring this casting into spec?

You must be registered for see images attach

FWIW, this would make me want to discuss what I have with the machinist, and see if he recommends balancing? Or this is normal & balancing is optional?

Q3: Is your new crank already machined on the flywheel end for

the tranny input shaft pilot bushing? (bearing?) Given that the

vast majority of new engines are connected to slushboxes, not

all cranks are set up for us 5%'ers. :0)

IF it

is machined, what is it machined for? Bearing? Bushing? What's the ID

of the hole in the center of the crank? (And at the same time, what's the OD

of the tranny input shaft that's expecting a bushing to support

the crankshaft end? Now that you have both, do you have the

exact right sized part in hand? Trust but verify, and I won't even

start the assembling/stuffing process until I've slid that bushing/bearing

over the tranny input shaft myself & the feel is confidence-inspiring.

And the same part then fits into the end of crank no problemo?

Color me overly cautious, but thanks to my stubborn desire to

keep driving a standard tranny, I *think* I've been burned every

possible way inside the bellhousing while attempting to marry engines

and transmissions from the far reaches of the automotive hobby.

Look forward to your reply. Best of luck with your home-brew

small block hot-rod stew!