Greetings GMTMark,

@Schurkey,

@Hipster,

@tpass all have very valid suggestions, and dropping the belt

is a very good, free to try, go/no-go diagnostic.

Assuming that eliminating the rotating accessories does not eliminate the startup noise,

then let's focus on the aural footprint for a moment.

First of all, my rule of thumb is the deeper the sound, the heavier the part that is the source

of that sound. Treble sounds are almost always related to the valvetrain, whereas upper block

area cold piston slap (up at the top 20-30° of the stroke when the spark plug fires & combustion

pressures rise) have a deeper tone.

Similar for a rod knock vs. a main bearing knock. The rod knock is a midrange sound, whereas a

main bearing knock is a deeper bass or almost a damped kickdrum-type sound.

****

Given all this, I found your observation that "this knock is located on the left front up close to the head"

gives credence to

@tpass's theory that it's cold piston slap. Also, the fact that the noise is loudest

shortly after startup (when the piston is coldest) and fades away after ~20 seconds reinforces this

theory, for the aluminum piston does grow rapidly from the combustion temps, and it only takes

a couple of thousandths of growth to stabilize the piston path in the cylinder bore.

I tell you all this because I'd like you to do the following for troubleshooting purposes:

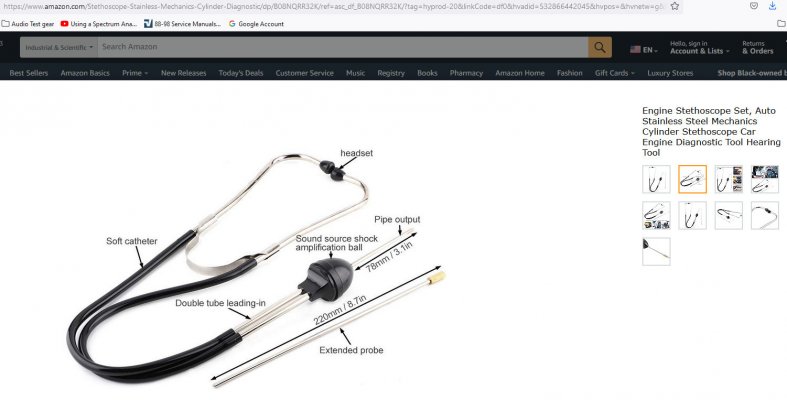

* Find, borrow, or buy a mechanic's stethoscope and see if you can pinpoint where the sound

is coming from. "Left front up close to the head" sounds like the source is the #1 piston?

* The next time the engine is stone cold, before starting it, temporarily remove the #1 spark plug

wire. Now if the noise does

not occur while the spark plug wire is disconnected, then we have

proved to ourselves that tpass's theory is the answer.

NOTE: Don't run the engine more than absolutely necessary to prove to yourself that the sound

has/has not been affected. On the one hand, the cats have yet to be warmed up & working,

but on the other hand with enough running the unburnt fuel could lead to an overheated cat.

With your problem description, only 10-15 seconds of running will be necessary to prove/disprove the

cold piston slap troubleshooting theory.

Q: Does this troubleshooting technique really work? A: Yes, I can vouch that this has worked for me.

****

1) If this was my vehicle, I would start with Schurkey's dropping the belt suggestion first.

2) If that doesn't eliminate the sound, then I'd try removing the combustion pressure

audibly slamming the piston into the thrust side cylinder wall next.

3) Before opening up the engine, again following Schurkey's recommendation a careful checking

for flexplate cracking between crankshaft & torque converter is in order. As mentioned above, sound

can travel in strange ways & fool even the most observant mechanic. (Note: In terms of odds, the

noise disappearing in ~20 seconds make the piston growth a 51 vs a 49 for the flexplate?)

We can't know for absolutely sure before going in, for stranger things have happened.

4) If the sound remains despite test steps #1 & #2, then Hipster's rod/main bearing theory

is what remains. (In my next reply I'd like to go into Hipster's front main bearing noise a bit deeper.)

Looks like you have several things to check out. Please reply back with what you

discover. I am looking forward to your observations.

Cheers --