a good friend and myself have a running joke about this. how the youtuber is the BEST on youtube. it's like this on every channelIt’s all just content made to get views at the end of the day. His YT comments are full of people who love him.

My GF and I were talking about this the other day. YT comments are FULL of people worshipping these creators. It’s so ******* weird.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

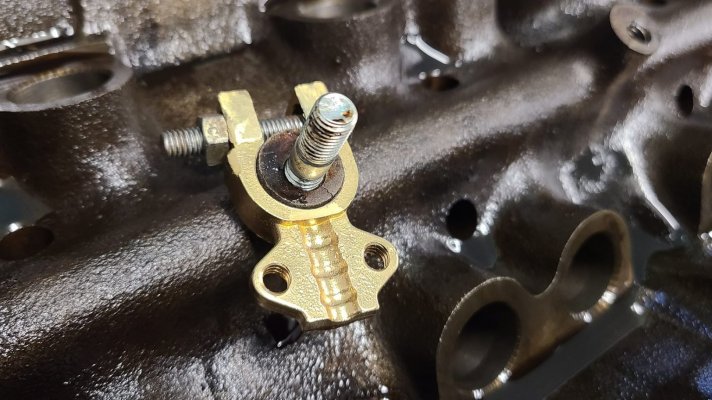

Broken Lifter Spider Mounting Hole

- Thread starter Majoraslayer

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Hipster

I'm Awesome

You guys read the comments? I usually don't get that far in before the "I'm done with this drivel" kicks in.a good friend and myself have a running joke about this. how the youtuber is the BEST on youtube. it's like this on every channel

i try not to, but this is usually in the top comments no scrolling requiredYou guys read the comments? I usually don't get that far in before the "I'm done with this drivel" kicks in.

Majoraslayer

I'm Awesome

Get ready, here comes your "it's so stupid it doesn't deserve to work, but it does" of the day. The piece broke clean, so I was able to clean everything really well and just set it in place like a puzzle piece. After grinding down on a spare battery terminal to eliminate the inner bevel and make it thin enough not to interfere with the spider mounting height, this gives a clamping force all the way around the boss without the worry of losing pieces of epoxy or JB Weld in the engine over time. The stud has a very good grip and is attached with red Loctite. I'm pretty confident that if that stud is subjected to enough force to pull this apart, I have another problem big enough that it won't matter much anyway.

Attachments

i would have never thought of using that to make a repair but it should work others may disagree. If it where me I would make sure to do something with that nut so that it doesn't back off and end up somewhere it shouldn't. Saying that might just be me overthinking though.

Hipster

I'm Awesome

Now that's some outside the box thinking! lol With the tray on it's captured so hopefully all works out. I'd be tempted to put a fender washer( small id big od) over it before the tin retainer, a little height difference probably not critical.

you- "A battery terminal will fix this" me-"Have you lost your mind????smh" lol

you- "A battery terminal will fix this" me-"Have you lost your mind????smh" lol

Last edited:

Get ready, here comes your "it's so stupid it doesn't deserve to work, but it does" of the day. The piece broke clean, so I was able to clean everything really well and just set it in place like a puzzle piece. After grinding down on a spare battery terminal to eliminate the inner bevel and make it thin enough not to interfere with the spider mounting height, this gives a clamping force all the way around the boss without the worry of losing pieces of epoxy or JB Weld in the engine over time. The stud has a very good grip and is attached with red Loctite. I'm pretty confident that if that stud is subjected to enough force to pull this apart, I have another problem big enough that it won't matter much anyway.

Brilliant!

i would have never thought of using that to make a repair but it should work others may disagree. If it where me I would make sure to do something with that nut so that it doesn't back off and end up somewhere it shouldn't. Saying that might just be me overthinking though.

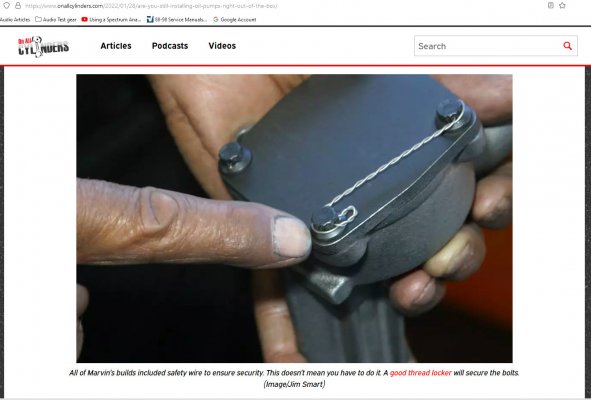

Your thought process is on the money. Here's how we make that nut stay in place forever:

Step #1: Buy a pre-drilled nut like this:

You must be registered for see images attach

Step #2: After tightening, safety wire drilled nut to immovable object like so:

You must be registered for see images attach

NOTE: See attached safety-wired oil pump cover bolts for an idea of what it

should look like when done.

By securing your cast iron reinforcement with a little bit of safety wire,

you will have an aerospace quality permanent lock on top of your

brass bandaid.

For what it's worth, I have *never* been let down by a quality safety-wiring,

and that includes numerous sets of eyes inspecting it after the fact, often

for weeks/months post repair. (Remember, I have to sign off/take credit for

all my on-aircraft work, and this documentation is a forever thing.)

As a matter of fact, if this was going into one of my daughter's vehicles,

I wouldn't hesitate to do this. (That's my highest rating. :0)

Whaddaya think?

Attachments

Last edited:

Majoraslayer

I'm Awesome

That would definitely be a great idea, but I kinda got ahead of you. Actually I did go back and add some reinforcement using inspiration from everyone here: I added some red Loctite to the battery terminal clamping bolt to make sure it stays secure, and I used blue Loctite on the top retention nut so it can still be removed if I ever need to work on the lifters. There's also a washer underneath the retainer nut so it has a good grip on the spider per Hipster's suggestion, and test fitting my intake doesn't indicate any clearance issues.

Hipster

I'm Awesome

Only thing left is to strength test your repair, grab your biggest bfh, wind up like a lumberjack......... no, no, no. lol

GMT400 in 20 years ...

Hey y'all, check this out! I pulled off the spider and found this! WTF?

Hey y'all, check this out! I pulled off the spider and found this! WTF?

Similar threads

- Replies

- 33

- Views

- 3K

- Replies

- 3

- Views

- 656

- Replies

- 2

- Views

- 322

Members online

- PM18S4

- Gordy_

- Chevyman1969

- rtbwmu

- gburg006

- 98tnk1500

- MARKD

- CumminsFever

- 93oldblue

- 89RCLB

- termite

- 1owner1990

- HotWheelsBurban

- RichLo

- Asjr1026

- Charlesteneows

- iz_lesa

- Sean Buick 76

- Caman96

- BigJake03

- CasillasJoseDaniel

- Trunzo

- Tom400CFI

- LTC_

- Beason

- rzr6-4

- Supercharged111

- caw_86

- man-a-fre

- Vikingdude

- Nostradamus1214

- 454ss1990

- Grassflatsfisher

- JBis

- Sdjones919

- jacob taylor

- PlayingWithTBI

- Zulu Kono

- Skip Fix

- Olemus14

- DavidH88

- GrimsterGMC

- scott2093

- Gezrcrew0406

- Murphdawg19

- Austindarksaber

- Alteca

- Olnickyjoe

- Gmcjon

- GeniusNdisguise

Total: 1,729 (members: 75, guests: 1,654)