stutaeng

I'm Awesome

Thank you for your advice. I can't feel any difference when I rub my finger or nail across that area. It just looks bad, that's why I think it's staining. The thing has been sitting outside for a number of years by now.Further consideration: I'm not used to using a 3-stone hone. Since my hones are different from your hones, I don't know what's normal for that style tool.

Is it possible that the "staining" you're showing on those cylinders is where the stones aren't touching the cylinder wall, due to some wear in the cylinder bore?

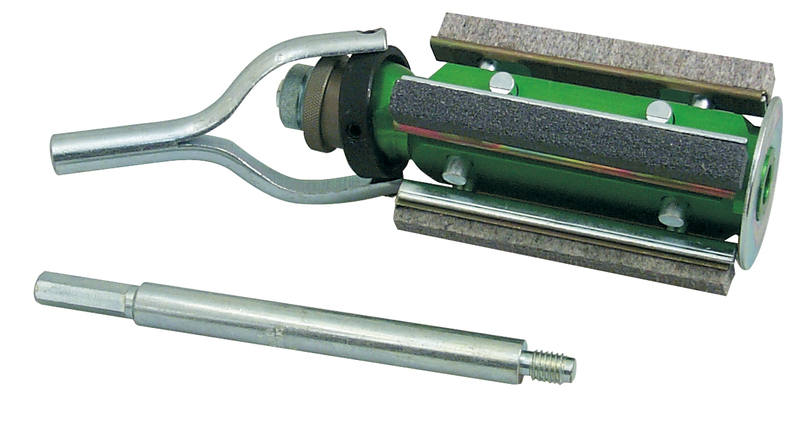

I'd really like to see you haul that to a machine shop for a professional opinion. I lean toward spinning a rigid-hone through some of those cylinders to see if they clean-up visually.

I decided to stop before I make things worse.

I'll take it a machine shop I called last week for evaluation.