he just built a 383 Mopar that was overbored .010" with standard pistons and drove it 2000 miles.

I worked for a company that had a "parts runner" van. They bored it .020, knurled the standard pistons, and twisted 20-over rings onto 'em.

Knocked like a diesel. That "rebuild" had 20K miles on it.

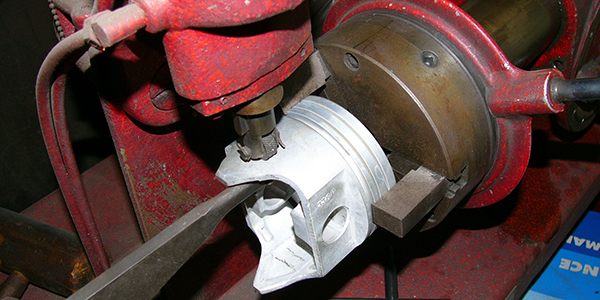

Knurling pistons (and valve guides) is mostly a lost art; a practice that's gone LONG out of style. Most piston knurling tools make a diamond- or slash-shaped impression, not so different from what you'd find on older ratchet handles.

Thanks to my late friend Pete Baldoni, a former NAPA store owner many years ago, I am the proud owner of a genuine Perfect Circle Piston Nurlizing Machine (Note: Perfect Circle spelled knurl with an N). Pete gave me that PC machine years ago, after closing the machine shop part of his NAPA store.

www.enginebuildermag.com

www.enginebuildermag.com/2017/09/lost-art-knurling-pistons-takes-skill-guts/

You must be registered for see images attach

The knurling tool set from Perfect Circle impressed the letters "PC" into the metal.

You must be registered for see images attach

Any way you look at it, knurling pistons is pre-1960 technology; when pistons were heavy enough to withstand the process, had giant skirts (or--like Buick continued to use--FULL skirts, not slipper skirts)

and labor was cheap.

Labor isn't cheap...but here we are, living in the age of VOWL-19, Biden, and automotive parts shortages so bad that my friend who owns the machine shop's biggest headache is getting parts AT ALL; it's a bonus if he can score them from a single warehouse so he doesn't have three separate shipping charges. Eight weeks out is good news, 'cause otherwise it's three months or Just Not Available.

So maybe piston knurling will come back.

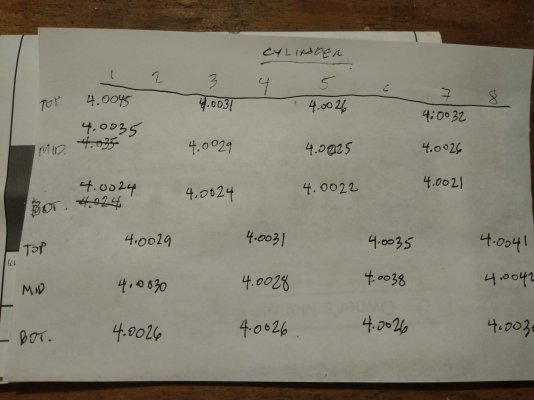

You might get some piston slap in cold weather if you hone it out to 4.0050", but I'd run it. The big question is whether you want to spend $300-500 boring the engine, buying new pistons, and having the machine shop swap the pistons onto the rods. If this is your pride and joy, spend the money. If you're a cheapskate like me, hone it and run it.

That's an option. I still want a pro to measure and inspect that block.

IF (big IF) the tools or technique were giving ~.002 error--the bottom of the cylinder was .002 larger than spec, and only about .002 smaller than the top, which MAYBE means the cylinders have only worn ~.002--a quickie hone might be all it needs.

It depends on your use case. I was watching something last night and the piston manufacturer spec'd .009 for a marine turbo application.

That seems like a lot. And a great deal depends on the expansion of the piston. The ancient "battleship" TRW forgings often called for .005--.007 clearance when run hard (and a Turbo would qualify), then add two more because it's a marine engine probably cooled by lakewater. The cylinders fight to get to 140 degrees--the barrels never get warm enough to expand like a normal engine, but the pistons are hot as hell.

Modern forgings generally need less piston-to-wall clearance; and a non-Marine engine with regulated coolant temp wouldn't need the extra .002.