I didn't do this...I remove the damper bolt and bigass washer. Set the washer aside, put the bolt with no washer back into the crank. Then the puller pressure screw pushes on the hardened head of the bolt instead of the cast-iron surrounding the threaded hole.

I'm going to try it. So you leave the crank bolt a little loose and the balancer pulls to it? Guessing there's not room to get a wrench on that crank bolt to leverage while using the puller?

edit/////guess I don't have the right sets of bolts... They're too short if I leave the crank bolt in... Have to grab some tomorrow I guess....

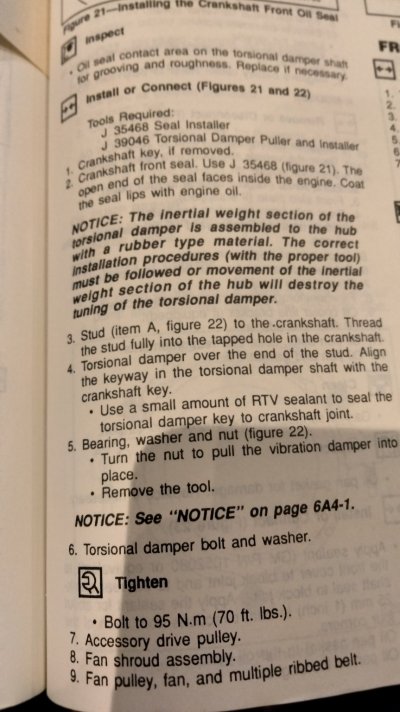

Here's a pic from video I saw...This is kinda what I'm thinking to remove this thing...

Attachments

Last edited: