ETA,

Your theoretical build of a LS-based endurance engine is an interesting proposition.

I have been looking, but it seems that there is a dearth of information for setting up

LS motors for 24-hour style racing? But there's plenty of info for short-duration

racing like the drag strip?

I got to thinking about this. Syracuse & it's suburbs are ~650,000 people. At the

local drag strip (

ESTA Safety Park) I'll bet that there is a max of 650 different participants

from the metro area during the year? So if you are a drag racer, you make up 0.1% of the population?

And what is the ratio of 24-hour endurance racers to drag racers? 1 endurance racer for every

1000 drag racers? Making you and your ilk such a tiny audience (0.0001%?) that

this is the reason for so few articles/discussions?

****

Anyway, there are countless articles about making huge amounts of LS power for short bursts,

but that's not solving your stated problem. You've already said as much, but it seems that the

key to success to still be hard charging after 24 hours of max effort is

thermal management.

Instead of discussing the obvious about cooling systems, I thought that I'd discuss an area that

may give you a performance & reliability edge.

More specifically, I'm thinking of cooling the underneath of your pistons using piston oil squirters.

(Note: Chevy does this to the LS9 & LSA motors -- both boosted from the factory.) Simply put,

the piston face is the bottom 1/2 of the combustion chamber, and normally ALL of the heat that

the piston gains during operation is sinked to the water jacket via the piston rings. Of course,

the center of the piston is the furthest away, so there's a distinct thermal gradient from the

center to the ring lands > rings > bore > water jacket. And this also helps to explain where

the majority of heat-related holing of the pistons occurs.

Meanwhile, the upper half of the combustion chamber is surrounded by the water jacket,

so the excess heat from combustion doesn't have nearly as far to travel.

So the idea of oil-cooling the inside center of the pistons makes perfect sense. Of course

there's always a tradeoff, in that you will need more oil volume from the oil pump, and also

that you really need to employ a good windage tray to take that (hopefully) heated

additional engine oil and get it back to the pan...instead of it all winding up in long hp-robbing

viscuous ropes around the spinning crank assembly.

Since GM reserves the piston oil squirters for factory supercharged motors, most folks

don't think it's necessary. But *you* the endurance racer are a 0.0001%'er, so even

though you staying NA, you are doing so for 24 hours at a time. Not only will you be

gaining piston strength (by lowering it's operating temperature) you can also avoid

having to use excess fuel for cooling like some do. (Or looking at it another way,

not having full power at the beginning of the race, but having the knock sensors/computer

pulling timing at the end of the race where you still need it all?)

EDIT: It was your 12:1 compression comment that got me to thinking about what

you would need to do in order to be able to up your mechanical compression ratio

without having to pull timing out of the tune.

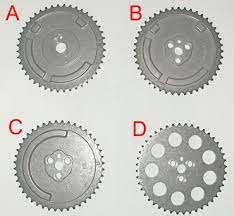

Poking around a bit, I found 3 photos of interest showing LS owners adding piston

oil squirters to their motors. (Discussion

here.)

****

And while we are busy thinking about keeping things cool while running nonstop

for 24 hours at a time, how about the valvesprings? Every time we compress &

relax a valve spring, this creates heat. In your travels around the interwebs, have

you read about anyone using oil to control valve spring heat in LS motors?

Bottom line, I think that doing this upgrade to a LQ9 endurance motor would

be something to look into. Food for thought...