stutaeng

I'm Awesome

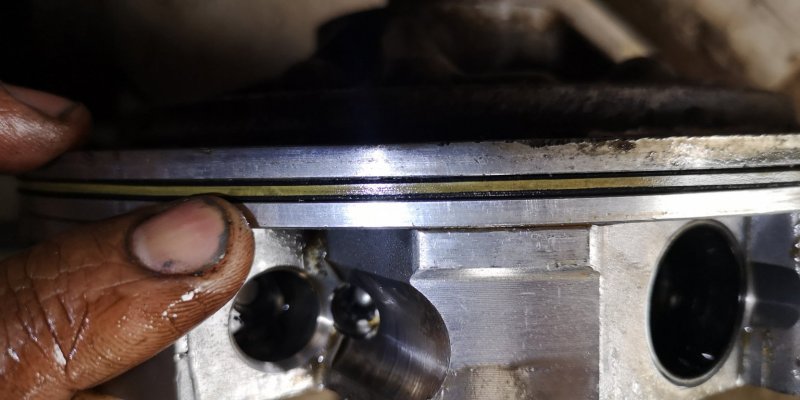

You will need a puller to remove the pump. Everyone (including myself) just stick a big flat screwdriver on the casting near where the red arrow is shown to gently pry out the pump. Be careful. The pump is heavy. Yes just remove the lockup oring, remove the bolts and pry out.

Get a new pump-to-case seal, lockup oring and the little seals on the pump bolts. It is recommended to install a bit of RTV on the bolts when installing as extra precaution to prevent leaks at the bolt heads.

I'm still confused though. Have you determined that the transmission is not burned up? Remove your oil pan. No sense in changing the front main seal if you find all the clutch material is on the pan...

How many miles or Km are on your truck BTW?

Get a new pump-to-case seal, lockup oring and the little seals on the pump bolts. It is recommended to install a bit of RTV on the bolts when installing as extra precaution to prevent leaks at the bolt heads.

I'm still confused though. Have you determined that the transmission is not burned up? Remove your oil pan. No sense in changing the front main seal if you find all the clutch material is on the pan...

How many miles or Km are on your truck BTW?

Last edited: