That’s really cool. I haven’t thought about making it appear stock. The distributor does mount to the front… you’ve got my wheels turning.I put an HEI 4 pin on a Mopar electronic distributor. Both the GM HEI and Mopar reluctors emit a square wave signal, so it works just fine. Mopar points, and electronic distributors use the same cap and rotor, so this works fine to hide it to appear stock. Just going to either ditch the ballast resistor, or hollow it out and put a jumper wire in it to complete the deception. Pertronix units work fine, you need to ditch the ballast wire or ballast resistor for them to work.

My buddy built a 68 chevelle with a 396 and put the ole fat cap HEI in it. Again not a big fan. I think those are the ugliest looking distributors ever made. They work great, but fit like crap. Anyhoo, the car would nose over at 4,500 rpm. I asked him if he removed the ballast wire under the dash going from the ignition switch to the coil. He said no. I told him to ditch it for a regular copper wire. Told him he wasnt getting a true 12V to the HEI. After that, this thing would pull hard to 6,500.

Heres pix of my GM HEI 4 pin Mopar electronic distributor. I made a homemade wire adaptor plug that plugs into the GM module, and Chrysler pickup. The other 2 pins go to an oil filled pertronix 50,000 volt oil filled ignition coil to complete the deception. The module mounting bracket I actually bought pre made off the interwebs. $25 it was not worth it to try to engineer anything similar.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom made shop tools

- Thread starter Moparmat2000

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Frank Enstein

Best. Day. EVER!

Get long bolts and cut the heads off. Screw them into the heads in place of the real manifold bolts in the 4 corners. Drop the manifold on and it will have no choice but to go into the right place. toss the distributor in just to make sure the holes in the block and manifold line up. Put the rest of the manifold bolts in finger tight, swap the corner bolts and torque away!A strap across the two rotor screws (or rotor) brought out, bent 90 degrees downwards, and clamped to the dizzy body might work. The body of the dizzy is plastic - so not the strongest to be working with.

I'll let you know how my tool works next week. Aligning the shaft within the body is easy - a gear tooth out is obvious from a marker pen mark. Providing the body can be re-installed accurately . By everything I've read - there is no overthinking this if a scan tool isn't at hand.

Tell me about it!

My inlet gaskets were supposed to be done last year in the summer - but so much other stuff got in the way.

If you are going to change yours - budget plenty time. EGR pipe soaked up time on mine and there's a lot of stuff to move/remove for access. I'm not looking forward to dropping the manifold back in - given it has to go in bang on square to avoid smudging the RTV on the china walls.

That is how I did it!Get long bolts and cut the heads off. Screw them into the heads in place of the real manifold bolts in the 4 corners. Drop the manifold on and it will have no choice but to go into the right place. toss the distributor in just to make sure the holes in the block and manifold line up. Put the rest of the manifold bolts in finger tight, swap the corner bolts and torque away!

Remembering back, I think there was a lack of height at the back corner on drivers side - manifold was fouling firewall and couldn't go back far enough to align with that bolt so had to ditch that one.

Two bolts diagonally opposite are usually enough for this kind of thing. This technique makes a massive difference for reassembling components secured with bolts. When space (height) is tight, slotting the cut down bolt to enable slackening with a screwdriver will allow it be shorter than than the depth of the hole in the component so long as final extraction with a magnet is viable. Do a dummy/dry run first!

You must be registered for see images attach

You must be registered for see images attach

I had one spare bolt that matched the threads and it was only 1” long so I couldn’t use that as the handle. It got shoved into the end of this Jack handle and hot metal glued.

Moparmat2000

I'm Awesome

May or may not be a custom made shop tool, but I needed an overdrive trans for a project I am working on. It was waaay cheaper to just buy a truck, part it out, and make a trailer out of the remains. Spent $400 got trans and trailer out of it, and sold $400 worth of parts, scrapped the rest. So I essentially got a free trans, and a free trailer.

Attachments

Last edited:

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

You must be registered for see images attach

Another IH scout tool… these clutches are supposed to ship with spacers that push the fingers down. I found another Jack handle, a scrap u joint strap and stuck it all together. First I made the wooden spacers that the FSM specs out but they weren’t even close so eventuallly I found three random spacers that worked perfect. Paint it all red to identify it as “special tools”.

Hopefully get the engine, trans, transfer case together and in the frame this week.

Moparmat2000

I'm Awesome

Not sure if it can be a shop tool, but it is making something useable for nothing. Son needed a manly man trash can for his room. I took a metal 5 gallon alcohol can from the scrap bin at work, and cut the top off. I cut carefully inside the lip, and there were no sharp edges. Going to put hot rod parts stickers on it. The smaller "wimpy" walmart one, I stacked his hot wheels tracks inside.

Attachments

Moparmat2000

I'm Awesome

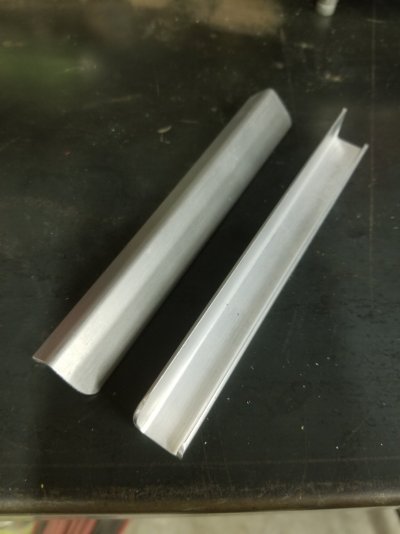

We do that at work ( the machine shop) all the time. Works grate.Picked up a bigger 6" vise from China Freight. Made soft jaws out of some small pieces of aluminum extrusion I had at work.

Similar threads

- Replies

- 58

- Views

- 6K

- Replies

- 95

- Views

- 4K

Latest posts

-

-

Really wish ppl would stop bringing me trucks with hydraulic fluid in trans

- Latest: 454C2500Longbed

-

Staff online

-

df2x44L60E Destroyer

Members online

- Striker1423

- Lmartinez7

- 454C2500Longbed

- dg60ford

- Dsperado

- HoosierK2500

- Wildcat465

- l1lartur0

- T3B3

- jimmyjel

- 97c1500G

- df2x4

- BeXtreme

- CletusPetus

- Gotcrits

- jimdaug

- Murphdawg19

- Drunkcanuk

- Fireball5657

- 1990Z71Swede

- crusty

- Frank Enstein

- ngaobs48

- Charlesteneows

- Alteca

- 94mexistepside

- jaddengripp

- Junior_97

- scott2093

- Krissies

- Hosstyle Motorsports

- jjester6000

- RQ Jay

- BEARDEDBASSMAN

- shaneroze

- Nostradamus1214

- Canadian Rust Bucket

- John Moore

- gunner70

- modernbeat

- Andre

- mehcs

- hohl

- kylenautique

- Griffin

- dizzysixx

- Seabee

- DerekTheGreat

- 0xDEADBEEF

- chevyshaw

Total: 1,662 (members: 59, guests: 1,603)