Also, could I take a multimeter to the knock sensor to ensure it's functioning correctly?

Greetings Moss,

Measuring the DC resistance of the knock sensor with an ohmmeter will only help to

prove/disprove gross internal connection failures. The fact that the live data in

reply #12 shows that the computer

is receiving a signal from the KS, which means

that we're probably past the point where a resistance reading of the KS will uncover anything.

(But even so, I still recommend the check, for at least we will know what the

problem

isn't, which helps to improve our troubleshooting confidence down the

road. Not to mention this bit of data can be obtained for free.)

Reading the output of the KS with a voltmeter while tapping on the block may or

may not give you helpful troubleshooting data. (Not everyone has an overachieving

Fluke in their toolbox.) An oscilloscope would really give you the necessary resolution to

see if the KS is reacting properly to stimulus. (Versus

over-reacting -- and this is the

question posed by the data graphs in reply #12?)

Problem is, this many years after it was made hardly anyone is still troubleshooting to

this level on a TBI SBC, so the only way you would be able to make an informed decision

would be if you had a 'known-good' reference knock sensor on hand that you could

swap in and then compare the results side by side with the original KS after identical

test drives.

But elsewhere in this forum we recently troubleshot a knock sensor issue, despite

having a couple of new, DOA, knock sensors from a normally trustworthy brand

thrown into the mix to make the troubleshooting just a little more challenging. :0)

If you haven't already seen this thread, if may help you become a little more familiar

with the knock sensor circuit: (

New KS x 2 no bueno -- NOS KS Good)

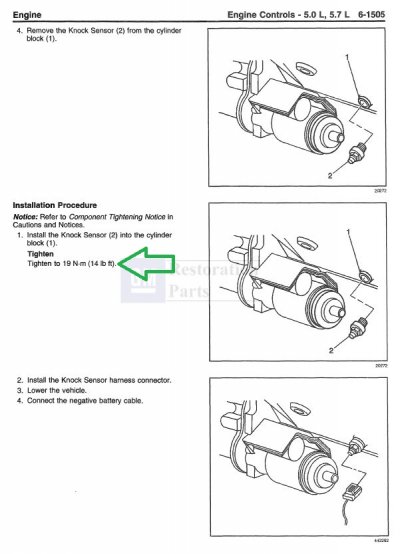

That reminds me, improper torque (~30 Ft/Lbs IIRC) on it can give you false KCs too. Maybe your FSM will help on troubleshooting it...

Over the years I have collected a bunch of GM service literature. Links to PDF Scans of service and STG manuals and a links to the Parts manuals. You'll need the FREE Adobe Acrobat reader to open these files. Get it directly from Adobe here {http://get.adobe.com/reader/} If you're not...

www.gmt400.com

^^^^ Like PlayingWithTBI said. Follow the Factory Service Manual's torque

recommendations (14 ft/lbs, see attached) and for best results, try to treat

this sensor more like it is a piezoelectric microphone instead of a lug nut

hammered on with an impact, and you should be good to go.

****

That's all I've got at the analog level for the knock sensor. I'm going to

step aside here and let some of the resident ECM/VCM tuner gurus

figure out if the knock sensor is so busy because of a over-aggressive

tune, a non-stock parts combo requiring higher octane that you are currently

feeding it, or even something as simple as 'too much of a good thing' base

timing cranked in at the distributor by some previous well-intentioned but

ham-****** mechanic. :0)

The bottom line is that since you are able to share live data, there's enough

talent & experience in this forum that a good solution should be found.

Hope you find the above helpful.

Best of luck!

www.gmt400.com