I had to run in after 1 minute to post this...wtf is this?

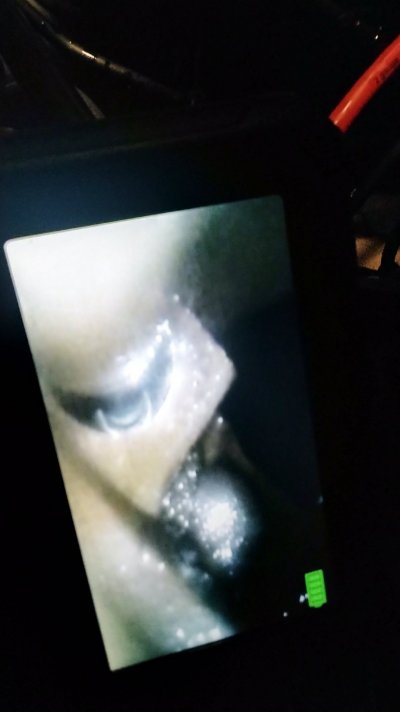

I was spelunking and happen to fall next to the oil pump drive.....distributor mounts above...at least I'm pretty sure that's where I went.....

I'll be back...

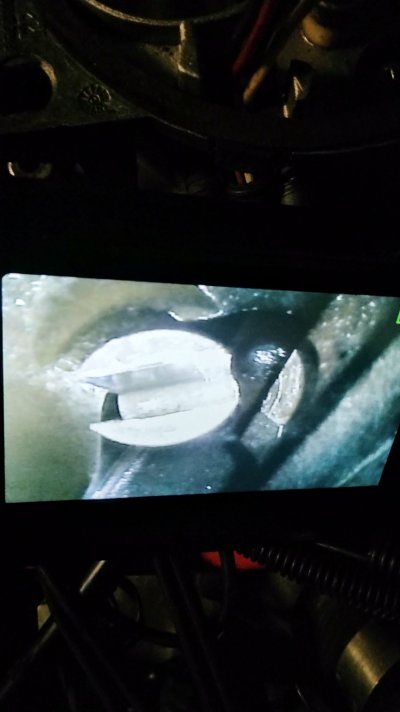

I've been pondering the photos you've posted in the vicinity of the cam/distributor gearing.

Although the low resolution images make it difficult to say for sure, it does look like there's

glitter residue below where these 2 gears mesh.

And I said earlier that *normally* the distributor gear wears first while the cam gear remains

in new condition. And if you think about it, you really want the replaceable gear on the distributor

to be ever so slightly softer than the non-serviceable gear ground into the cam core.

And this is what happens when you mesh the correct distributor gear with the camshaft. And since

this is a roller cam-equipped engine, unless the engine came with a brand new distributor from the

remanufacturer, no doubt the expectation was that the customer would install a

Vortec distributor (or TBI dizzy

upgraded to a Vortec-style gear)

that's compatible at a metallurgical level with the roller cam.

I know it's been awhile, but when this engine went into your '93 ~15 years ago, did this crate engine come with it's

own distributor, or was the old distributor from the original TBI engine installed into this engine?

IF the old TBI distributor was installed into this (Vortec style) roller cam engine, then we may have figured

out where the glitter in your oil is coming from. (Reply showing excess metallic glitter in engine oil. LINK to Reply #107)

Here's what John Lingenfelter said about this scenario back in the early '90s when the new steel core roller cams

were just coming out:

You must be registered for see images attach

Given the underlined sentence above, check out this comparison photo of a Melonized distributor gear versus the original cast iron gears that we

all grew up on:

You must be registered for see images attach

(credit: On All Cylinders article:

Distributor Gear Compatibility: How to Choose Which Distributor Gear to Use -

Short article - Recommended Reading)

****

Now to pull this all together and take all of your latest findings and try to turn them into a plan of attack.

I'm going to list a bunch of questions, and your answers will help determine the path from here.

1) In this reply back on March 7th you showed us oil drained from your engine that had that metallic

paint look to it. At the time we hadn't figured out that your 'TBI-era Yukon' wasn't running a flat tappet

cam that matched the one that it came off the assembly line with, so I was thinking that one or more

cam lobes and/or lifter bases had been worn away.

But once you started removing the roller lifters for inspection/cleaning and the pics of the intact cam lobes and lifter

rollers were posted, the mystery deepened. Except for piston rings, there aren't that many other places where magnetic

debris can be generated. If your roller cam engine ended up with the old TBI distributor (with the cast iron gear that's

incompatible with the roller cam) ...then the photos showing an unworn distributor gear but worn cam gear now makes

sense. And would also help to explain the glitter in yesterday's photos.

And IF the current engine oil is just as full of fine metallic debris as what you removed ~6 weeks ago, then this may

help to explain why your lifters aren't staying pumped up after shutdown. When you have this much metallic debris

showing in your oil the engine it came from is never as quiet as a fresh engine with clean oil and all factory clearances.

I don't want to be a Negative Ned, or on the other hand traffic in false hope, but the status quo is unsustainable.

We need to stop the

generation of debris asap. Somehow get the debris out of the engine. Evaluate the current

health of the rings, bearings, oil pressure at hot idle and on the highway, and finally, careful measurement of

current oil consumption in how many miles per quart?

If we were neighbors, I could see this playing out a couple of different ways. At one extreme you need the truck

healthy sooner rather than later, and declare that after 15 years of service the engine in the engine bay has

finally crossed the finish line. You swap it out with a Jasper-level roller cam reman. And if the reman engine doesn't

come with a dizzy, put a Melonized gear on the dizzy you've got and away you go. Buy once, cry once, drive much.

At the other extreme you decide to just upgrade the distributor gear to a Melonized one, start changing the oil

every 1000 miles or so, roll the dice, and see what happens. In the land of unicorns & rainbows, the new dizzy gear

all but stops the cam gear wear, the engine oil eventually stops looking like metallic paint, the oil consumption

is within reason, and the hot engine oil pressure stays in the 10 lbs per 1000 rpm range. And best of all, with clean

oil the lifters quiet down, and no longer bleed down between trips.

* Or do you replace the dizzy gear AND a roller cam with a NOS factory takeout in new condition?

* Or do you replace those 2 items and add 16 new roller lifters to the tally?

* Or do you decide to pull the engine, strip it down, get it absolutely clean, hone/rering, fresh bearings,

oil pump, gaskets, etc? Where do you stop? Do you have the heads refreshed too?

There's some real calculus required to come up with the best answer for this scenario. On the one hand,

after 15 years of service this engine doesn't really owe you anything, and if the rest of the truck still has

plenty of life left in it, then maybe cutting clean and plugging in a new motor is the best answer? If you

do that, you really have to read the fine print and make sure that you don't run afoul of whatever warranty

requirements are in place that preserve your ability to make a claim if something were to go wrong post installation.

If all depends on how deep is your fleet, and just how bad your family needs the vehicle for essential transportation

versus performing double duty by providing you with something to hone your mechanic skills on?

There are probably as many well thought out opinions on this as there are members. No doubt there are those who would lower the

hood, turn up the radio, and just use it up until it fails to proceed. (Treat truck as replaceable old appliance.) Then there are others

who, for sentimental reasons, would decide to repair the truck instead of going out and looking at the cost of a new/newer

replacement.

Lot's to think about. Anything can be fixed, that's the easy part. The hard part is figuring what is the optimal

measured response to the problem at hand.

That's all I've got, but at least on the technical side of things we're starting to piece together what's really going

on with this clacky powerplant. And thanks to the borescope photos you've shared, I have upgraded my

personal borescope purchasing criteria from purchase to invest.

Wish I had better news to share. It's all fun and games until somebody gets the metallurgy all crossed up.

And unfurtunately, the newer the engine, the more fussy all this stuff becomes. Cam phasers and timing chain

kits can be breathtakingly spendy. :-(