in my truck specifically, if ending up in a scenario that warranted it ,I would need a new type of cam (roller) and could run something like these? Sorry if that's obvious. Trying to put names to faces with some terms I've heard.

But back to the visual inspection. If I were to look at them all and find 1 or 2 damaged lifters, the chances of the cam lobes being goofy are high enough to be thinking of replacing the cam and all lifters?

What if the cam looked good? All lifters that look and tested good go back to their original spots and new lifters (Delphi)? can replace the damaged ones? Or better, new lifters can be used with the existing cam if not damaged

I'm pretty sure I'm seeing metal particles in my oil from changing last night. My tubs are so contaminated that I can't be sure how bad but, peeking down the oil filter with a light and layering my 1.25 and 2.75 readers..lol...I can see something glittery in the small amount of oil when really focusing. My optivisor 10x are a bit too bulky I'd imagine.

I've read that the oil filters themselves can shed aluminum but, the look of the tub I dumped oil into has me doubting that is the case.

I plan to cut the filter open in a while once I can make some noise to see if I can find anything.

Assuming I do, I obviously need to start planning my next move. Hoping that the engine treatment is just cleaning off stuck stuff that happens to look suspicious would be nice but, the intake gaskets are coming off as soon as I can get to them and, I'm guessing that is the time to dig deeper. I need to start reading up and learn about valve removal and all that....

I'm obviously a fan of keeping things going and do get satisfaction from doing the minimal necessary to do this but, time is very valuable and if I'm understanding right and a new cam and lifters is an option, in my hasty opinion atm it sounds like my focus should be directed there at least to some degree?

Hope I'm making sense...

This thread is like the opposite of people talking over each other..

Like dumping years of coins in a pile to grab all of the quarters first, and going back to make sure you actually did get all of them and finding several more ... and a few Susan Bs

Good morning Scott,

Due to the underlying complexity of a modern valvetrain, we've been forced to cover a *lot* of ground during this thread.

Which certainly can be confusing. And doing this remotely via the written word makes this even harder.

It's one thing to describe a finite task such as how to replace the air cleaner element on a GMT400. It's quite

another to describe how to evaluate valve train noise and then attempt to quiet it in the least number of moves.

And at some point the task is so complex that the written word is insufficient, and instead textbooks, some video,

formal lecture/lab, and possibly working under a mentor is a common-sense requirement. (Think open heart surgery. :0)

But with a willingness to learn and an ability to not let frustration boil over I think that it *is* possible for a solid DIY guy or gal

to learn enough about adjusting the valves on their engine remotely, either as a diagnostic tool (to help figure out which part{s}

have reached the end of service life and require replacement) or as a way to set up a collection of good parts for many years

of quiet, smooth operation.

Elsewhere in this forum there are threads where something complicated like an engine swap has been attempted

as a necessary evil to save money instead of a desire to add a new skill or an opportunity to learn more about how

to be more self-reliant with your ride. It's hard to watch (even remotely) when someone is hitting snags and hating

every second of the project. :-(

****

But from here it seems that you've maintained a positive outlook on all this despite a steep learning curve.

And I remember back to last October when you successfully worked through not 1 but 2 brand new, bad

AC Delco Knock Sensors simply by making the measurements, following the data, and eventually finding

the fix via a NOS part. That was a good fix!

Given all of the above, I think that we should pause, take stock of where we are, go back and reread

some of the replies in this thread to help cement a mutual understanding of how this mechanism works,

and then come up with a plan that will minimize the risk while maximizing the benefit for you. (ie: I don't

want to be the Pied Piper that talks you into tearing apart the vehicle you need in order to get to work just

to fix a nuisance noise that isn't going to affect the overall reliability of your vehicle.)

****

As for the noisy valvetrain, I firmly believe in a measured response to any problem. Here is what the path

looks like:

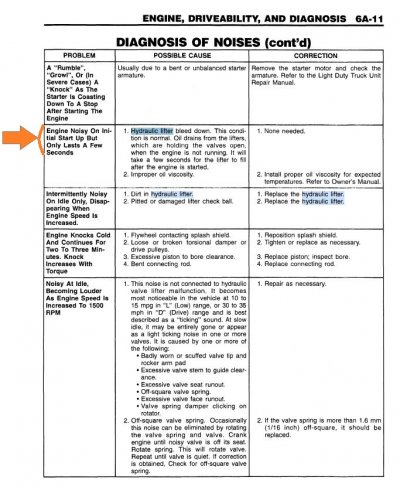

1) Occasional lifter noise immediately after startup, which subsides after a few seconds. Per GM's own FSM, this is normal

and acceptable, no maintenance required. (See attached.)

2) Steady lifter tapping that does not subside from one, a few, or all 16 assemblies. The noise is cured via

external adjustment. And stays away. Problem solved with zero hard parts, just labor, gaskets, & oil change.

3) One or more lifter assemblies remains noisy despite the adjustments in step #2. The noisy lifter(s) are removed,

pass a careful visual examination for excess exterior wear. The diagnosis is suspected varnish buildup not allowing the

inner lifter parts to move as needed in order to keep the rest of the valvetrain assembly in a state of zero lash. Lifter

is disassembled, cleaned, reassembled, verified that it pumps up properly, reinstalled, and the preload set. Noise

goes away and stays away.

4) IF we arrive at this step, it's because the lifter

failed the visual inspection in step #3.

Decision time.

4a) Put back together, set preload for quietest operation, and drive vehicle until engine fails, send worn-out vehicle to

junk yard.

4b) You have a backup vehicle, allowing you enough time to pull the existing engine, remove all debris, refresh the

rings & bearings, new cam/lifters/timing chain, refresh the cylinders heads, etc. This takes time.

4c) You don't have a backup vehicle, but you can afford to be down for a weekend. While driving on the existing engine,

you locate a rebuildable donor out of the treasure yard/running 350 in a donor vehicle/reman engine from a parts store with

a warranty/GM crate motor/etc. Once the replacement motor is ready, start pulling the old motor on Friday after work,

and by Sunday afternoon have the new engine installed, fired up, and ready for duty.

5) After evaluating Step #4, you decide instead to take it to a trusted mechanic and have them do what it takes to install a

lasting fix in the engine bay. NOTE: If the cam or lifters have worn down until they became noisy, then paying a mechanic

to only change the cam & lifters on the existing motor is

not a lasting fix. In this situation, there is simply too much hardened

debris inside the motor that will cause the kind of wear that will eventually lead to a plummeting oil pressure > failure.

****

The above is pretty much the unvarnished truth about your situation. I'm hoping that after a careful Step #2 is performed

(either cold or running preload, your choice) that your engine reverts back to Step #1, and this remains the status quo for

many miles. This is *still* a possible outcome. Going from here all the way to Step #3 for one or two lifters is also possible,

and again assuming the parts involved pass a careful visual inspection, this devarnishing can result in a quiet valvetrain,

allowing you to revert back to Step #1 for a long time.

It's when we have to escalate to Step #4 or Step #5 (after one or more parts fails a visual inspection) that things get expensive in

a hurry. And all of this involves a cost/benefit analysis that

only you can make for yourself.

Again, I'm all about a careful evaluation of any noise, followed by a measured response. And an engine that's quiet enough for

a 27 year old DD may not be quiet enough if swapped into a powerboat. So when it comes to noise, there's no one right answer,

but instead a range of acceptable answers, which depend upon the priorities of the owner.

I'm going to go back and reread this thread so that I am sure that I've gotten my explanations right. Please give those 5 levels of

measured response some thought, and afterwards we'll figure out what is the best common-sense path forward for your situation.

Cheers --