Picked them up a month ago because they where cheap, and because I really like steel wheels

They are OEM 16x6-1/2 from a 91-2500.

I'm contemplating having them widened to 9 or 9-1/2" and Painted black.

Not sure if that is doable though seems there is not enough lip to start with. Also, they seem REALLY heavy, are 2500 wheels different from 1500 wheels?

1990Z71Swede, I share your enthusiasm for steel wheels. And I

always notice

when I see OEM steel wheels from the side, but when I walk around to the front

or the back I see that there's a more generous tire width showing than expected?

I like that even more!

Anyway, like

@RanchWelder recommended in reply #26, getting the right person

involved in widening the wheels is going to be the key to the success of the outcome.

If it was me, I would set myself up for success by doing the following in order to

end up with wheels that not only look good but also drive so smoothly that I

look forward to each & every turn behind the wheel.

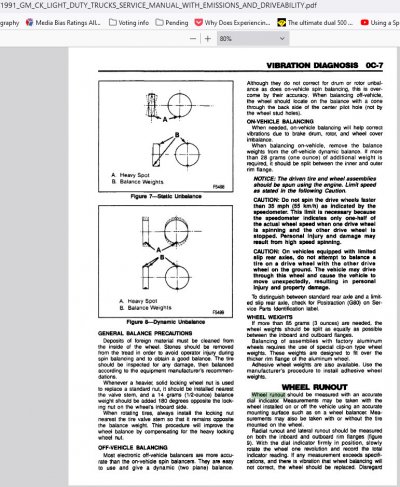

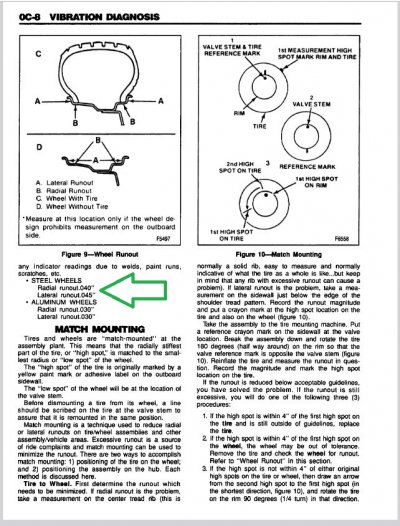

1) Before I do anything, what is considered straight enough to give me a factory

smooth ride? According to the Chevy Engineers, in the Vibration troubleshooting

section of the '91 Service Manual they want to see a maximum of .040" radial

and .045" lateral runout in the customer's steelies.. (See attachments #1 & #2 below.)

2) Are the wheels I have straight enough to be a good starting point for this

project? I'd dismount the right front tire on the truck, and then cycle all 4

wheels through my new test station, looking for how straight each wheel was. (Bonus

points for actually quantifying the vertical & lateral runout with a dial indicator &

writing it down for each wheel. (example: See attachment #3)

3) OK, now *I* am ready to talk to the machinist/welder/magician. You see,

I've learned that when I've got something I really want done *right*, I have to

come across to the other guy like I've done my homework. If I show up with

no specifications & ask if they can widen my wheels, the response you get is

something like this: "well SURE, piece of cake, no big deal!" And afterwards,

no matter how much/how little you pay, it's a complete crapshoot if I get

perfect circles, egg shapes, or something inbetween from the dude.

On the other hand, when I show up with the factory specs + my own

measurements, and ask him if he has the capability to widen my wheels

and still meet the factory limits, then he knows that I know...if you know

what I mean.

And sometimes this is the most important part of the

deal...'cuz although I'd never say that I was going to check his work, by

the same token he is already convinced that I am going to. Good!

From my perspective, I'm simply trying to figure out if this guy is willing to work

with me to achieve results that are worth the money I'm investing in the project.

(And I'm always professional & polite when discussing this stuff. I've always found

that the pros that share my enthusiasm for quality are always super easy to talk to. (!)

And you know what? Early on in this hobby I didn't do my due diligence/homework

before talking to prospective machinists, and this led to several disappointments.

But after deciding to not quit this hobby & take up golf, I got wise and

made sure that I was fully up to speed

before going through the

project interview process with a unknown entity.

Bottom line? Once I ask the right questions, the guys that aren't into the

accuracy always come up with a reason why they can't do my work. And

after talking to a few folks, you find the one guy that can not only meet

the GM specs, he will tell you that he gets them a lot straighter than that!

*That's* the guy you want to do the work for you. Especially if the

local racers also sing his praises.

That's my 2¢ worth. It won't be easy, but it would be well worth the

effort. Happy hunting for the right talent --