after a few months of saving up some funds I made a stop by my local drive shaft shop and custom ordered front and rear shafts. No Bluetooth driveshafts for the truck!

The shop recommended a single piece aluminum rear shaft and heavy walled steel front shaft with full length splines

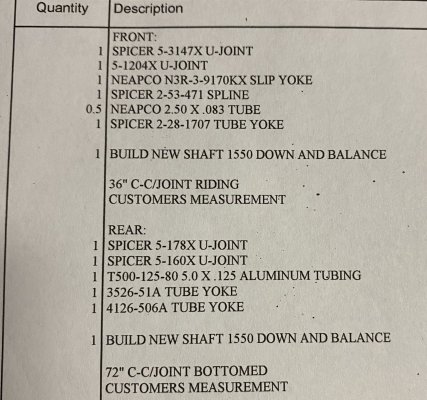

All the details are in the attached order form sheet. For anyone else interested in a Cummins swap driveshaft measurements for this vehicle here you go!

Current application for a 72” rear shaft and 36” front shaft

1997 k2500 ECLB frame with a 6bt/4l80e/np241c drivetrain using the oe 32 spline slip yoke. ‘97 Ford Dana 60 front axle, ‘05 AAM 11.5” rear axle with ORD’s SAS kit up front and a ORD shackle flip on the rear. OE ‘97 k2500 rear leafs with cheap 47” front leafs

The shop recommended a single piece aluminum rear shaft and heavy walled steel front shaft with full length splines

All the details are in the attached order form sheet. For anyone else interested in a Cummins swap driveshaft measurements for this vehicle here you go!

Current application for a 72” rear shaft and 36” front shaft

1997 k2500 ECLB frame with a 6bt/4l80e/np241c drivetrain using the oe 32 spline slip yoke. ‘97 Ford Dana 60 front axle, ‘05 AAM 11.5” rear axle with ORD’s SAS kit up front and a ORD shackle flip on the rear. OE ‘97 k2500 rear leafs with cheap 47” front leafs