Okay so I went through hell since Wednesday I worked on the truck day and night. The truck WOULD not fully start for the life of me no matter how many times I put the engine at TDC. Everyone kept saying timing, timing, timing.

heyitzjoel,

Believe it or not your problem really was timing, timing, timing.

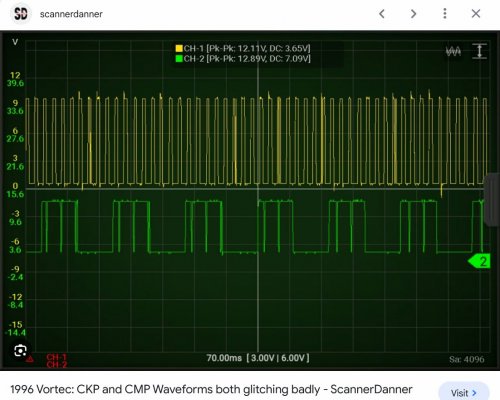

Absolutely everything having to do with triggering the fuel injectors

to firing the spark plugs are 100% dependent upon the master signal,

which we refer to as the CKP signal.

From a safety standpoint, if the ECU can't 'see' that the engine is spinning,

it will absolutely not fire the fuel injectors. There's a lot of sensors that, if

they drift out of calibration, the ECU will substitute a 'nominal' value and keep

the engine running, albeit with a lesser efficiency and power delivery.

But without the all-critical CKP signal, there's no life in the engine bay.

And there's the 4 levels of troubleshooting based on increasing test equipment capability/resolution.

* Old school voltage measurements using a multimeter & following fault trees. (No ECU codes, you are on your own.)

* Code reader. OK if a code is stored and the fault trees are extensive enough.

* Scan tool with live data display capability. A large step up, for now we get to

know exactly what the computer is made aware of, is it being lied to, and how it has

decided to respond.

* And then there's the scope dudes who look at the raw analog signals in order to

fix beyond what the computer was programmed to anticipate understand. This proves helpful

when a signal or sensor has failed in a way in 2024 that wasn't anticipated by the

designers back in the '88-'98 timeframe.

It goes without saying that the higher you go with test equipment resolution the

easier/faster it is to locate a tough no-start like this.

To do this with just a multimeter is no mean feat.

Well played.

Attachments

Last edited: