if you have a suggestion i'm all ears, I couldn't find anything.

Here's an example of the detail one can find, on RockAuto anyway for Hayden p/n 2614 (take this link and scroll down to see the matrix of specifications, look for the measurement they give on

Overall Height and use this to compare different clutches):

Also note the Rotation (reverse or standard), the Fan Bolt Circle (it needs to jibe with the fan you're trying to mount), and the Fan Mount Diameter (the pilot hole in the center of the fan needs to be this big or larger).

Hayden's site may have this information as well.

I've a list of

part numbers you can check, below. Read on...

Back around 2004, I went into a NAPA, looked through all (or most of) their clutches appropriate to my application, and measured them, looking for a perfect fit for my S10 (w/ L31 retrofit, as radiator clearance was an issue).

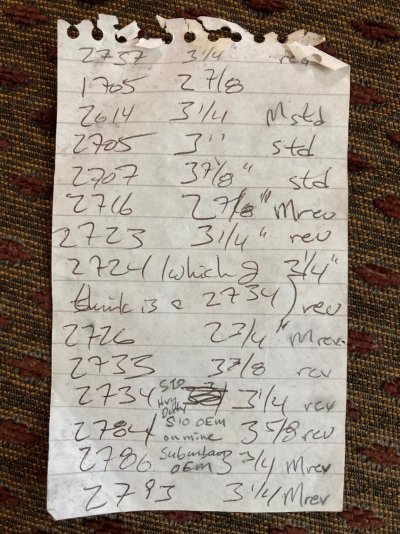

Here's the scrap of paper with my notes (attached). These are both regular and reverse rotation clutches, and those with thread-on style mounting (1996+ water pump) and pedestal mounting (1995- water pump).

Looking over them now, it seems there was about 1" of variability between the shortest and the longest.

Those are Hayden part numbers (4-digit) and may cross to others.

My notation was:

Part number : distance : threaded ("M") or pedestal base (blank) : rotation (std or rev)

I won't guarantee the accuracy of these notes. Check on-line or in-store.