Awesome! Thanks for all the help everyone...

So, when trying to test knock sensor ac voltage output, it's so cramped in there, I can't get a good whack at anything while holding three things at once but I can see maybe 100mv on the meter when I tap lightly on the ks housing. I know the tek scope can pick up just about anything but I'd be wanting to see the signal do something with the computer ultimately so I'll wait to bring it out I guess.

too bad I can't see knock counts in memory? Maybe I can?idk.... hard being solo. Could drive with scanner but, I need glasses to read things like the scanner but can't drive with them very easily...I could then at least see what that pinging is doing. It's easy enough to duplicate..

I'll get some extra hands and eyes to really try..,... when I was able to see the scanner and whack the intake pretty good, I wasn't looking for voltage. Just looking for knock activity on the scanner. I feel pretty good I can get it to produce some good signal/voltage on the meter when I try looking at that. Hopefully anyway.

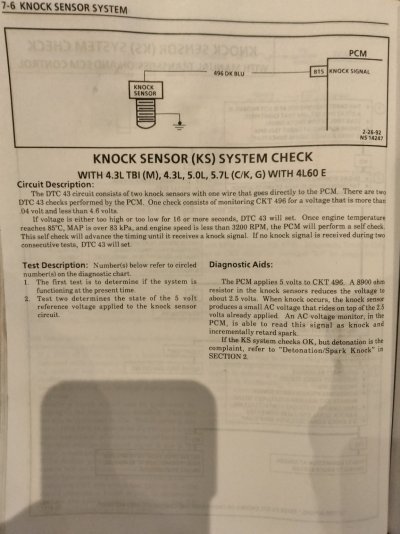

Maybe the scanner won't pick up anything until certain conditions are met anyway is what I'm hearing? Or just being able to see the timing retard won't happen until certain conditions are met? I did see something about how the DTC 43 needs certain conditions to be met or something. I'll get a shot of that blurb in manual...edit...added pic

Which is going to possibly leave me with why, after seemingly needlessly replacing the knock sensor, am I getting this new pinging? Knock sensor too tight? Too loose? Coincidence I got some bad gas pretty much the same time? Man I hope it's not something worse. Flexplate or something...

The emissions manual says "engine idling at normal operating temperature. Tap engine near sensor to look for knock signal on scanner"... I tried that..

Has me a little concerned I drowned the new sensor but so far it seems like maybe it's ok. I'll see what kind of voltage I can get out of it with some good whacks... I'll give it a go tonight after work. God willing of course.

thanks again..

So, when trying to test knock sensor ac voltage output, it's so cramped in there, I can't get a good whack at anything while holding three things at once but I can see maybe 100mv on the meter when I tap lightly on the ks housing. I know the tek scope can pick up just about anything but I'd be wanting to see the signal do something with the computer ultimately so I'll wait to bring it out I guess.

too bad I can't see knock counts in memory? Maybe I can?idk.... hard being solo. Could drive with scanner but, I need glasses to read things like the scanner but can't drive with them very easily...I could then at least see what that pinging is doing. It's easy enough to duplicate..

I'll get some extra hands and eyes to really try..,... when I was able to see the scanner and whack the intake pretty good, I wasn't looking for voltage. Just looking for knock activity on the scanner. I feel pretty good I can get it to produce some good signal/voltage on the meter when I try looking at that. Hopefully anyway.

Maybe the scanner won't pick up anything until certain conditions are met anyway is what I'm hearing? Or just being able to see the timing retard won't happen until certain conditions are met? I did see something about how the DTC 43 needs certain conditions to be met or something. I'll get a shot of that blurb in manual...edit...added pic

Which is going to possibly leave me with why, after seemingly needlessly replacing the knock sensor, am I getting this new pinging? Knock sensor too tight? Too loose? Coincidence I got some bad gas pretty much the same time? Man I hope it's not something worse. Flexplate or something...

The emissions manual says "engine idling at normal operating temperature. Tap engine near sensor to look for knock signal on scanner"... I tried that..

Yes it was coming out good...it sucked.....maybe like when you're past halfway through draining the oil.Unless there's debris in the hole, or the radiator cap is still tight...the coolant should have been GUSHING out of that hole.

Has me a little concerned I drowned the new sensor but so far it seems like maybe it's ok. I'll see what kind of voltage I can get out of it with some good whacks... I'll give it a go tonight after work. God willing of course.

thanks again..

Attachments

Last edited: