Ok. I'll do it in the am.. Tbh, I didn't let the engine warm up too much and it could have/probably was still in open loop.. not sure if that would matter or if I wasn't paying attention..pretty sure it stayed retarded though...That's NOT what I'd expect. The knock sensor when activated, should cause the timing to retard for a few seconds. Not "permanently". Your regular timing advance should come back by itself, probably not more than ten seconds. Five, maybe.

Now I'm concerned again.

Whack it again, see if the idle slows, then recovers.

hmmm. so 3v?I just rewatched my old video in Post #10, and I had channel A set to 1V/division,

so with light tapping I was able to get a 6 division peak-to-peak output displayed

from the sensor alone. (Unpowered, not in circuit, just working into the high

impedance of the o-scope. Peak output could well be different in circuit.)

Hopefully my little janky vice set up and balancing act with meter leads and force was was just different or these sensors are different specs?

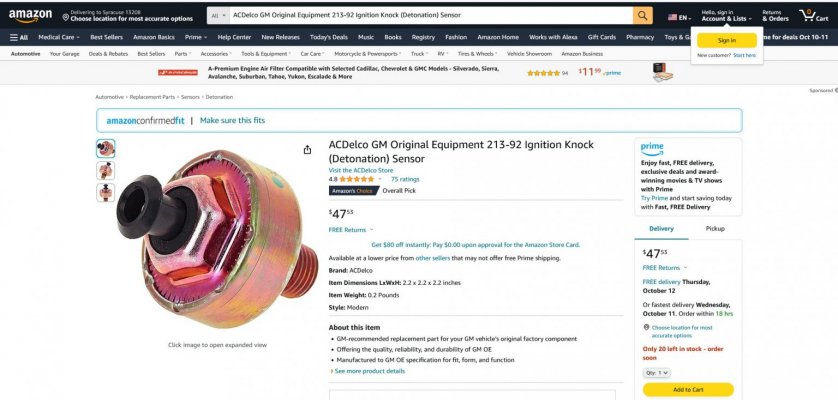

I still want to get a new one. Especially now I have the plastic bag trick..lol

The old one looks pretty rough and the terminal had play where the new one didn't . almost like a plunger action where I actually made the extra effort to squeeze the connector to attach it to keep it from moving. Not sure if that's supposed to be like that or not.

I mean I did get the signal pretty easily and the timing did retard but, maybe it's supposed to be more sensitive. I'll test it's output tomorrow with it installed....

Was nice that it had proper ground at 14lbs torque.

Not sure if I feel good assuming the new sensor was goofed from the get go. It did take a bath in antifreeze and I did have to torque it to, would guess maybe 35lbs to get ground... Maybe that was from the bath..idk...

Thanks again!

Attachments

Last edited: