Ok, this is probably the last update for this one, barring an unforeseen disaster.

Parts list...I only replaced the aux hoses. The ones for the front heater looked almost new, they can't be more than a couple of years old. So I only went from the splitter in the engine bay to the rear of the truck.

On my truck, all the hoses were 3/4". I saw some conflicting information out there about that. Dorman 800-411 is the quick connect that fits that hose and the metal lines; you'll need four of them. I used just shy of 6' of hose...if you're replacing the front hoses, you'll need more. I didn't replace any of the metal lines.

A clearer description of how GM set this up: Beneath the air intake box on the passenger side of the engine bay, you can't miss the splitter. From there you can follow the hoses to the regular heater core, and to the engine and radiator. You'll see the two quick connects next to the exhaust manifold, and the hoses they're crimped to are wrapped in some thermal protection stuff. The hoses head downwards and aft, and just out of your reach they are crimped onto aluminum tubing; the two tubes are clamped together in a couple of locations. That aluminum tubing is pre-bent to fit around the frame, with a small bracket that bolts to the inner side of the frame near the front wheel. You can easily see it from beneath. Then the tubes continue just behind the front wheel and bend outward and poke through a hole in the frame, with another bracket that bolts to the frame where they poke out. From this bracket all the way to those plastic quick-connects, both lines, is one assembly. If you can find it, buy it. If you can't, you should be able to take it apart and re-use all the metal parts and just replace the hoses, plastic connects, and the heat wrap. Note that my parts list above does NOT include this, so that's 2 more connects and more 3/4" hose. Shockingly, the assembly is not difficult to maneuver out of there. You'll end up spinning it about 180* and shoving it further back, then getting the front end free first. Installation is the reverse. I expected this to be the worst part of the whole thing, but it took about 2 minutes to actually get it out, and less to slide the new one in place.

From here I'll only mention one line, but both of them are virtually identical and run alongside each other. The only differences is a couple of inches of rubber hose just based on bending radius. At the connection point poking through the frame, there's a quick connect hidden under a boot (the front assembly comes with the boots, and I wish I could've found them to use on every connection), then 6-10" of rubber hose crimped onto more aluminum tube. I didn't mess with that tube at all...it's well mounted and in good shape. It's prebent to go all the way back and over the rear axle. At that point, another crimp to a rubber hose that makes a large bend (make sure you don't kink the hose), then a quick-connect into the aux heater core. I'll be wrapping these quick-connects in electrical tape or something...the boots GM used elsewhere really made a difference in being able to remove these things, so I want to do something to protect them and keep crud out in case I ever have to mess with them again.

Here's the FSM diagram, which isn't of great help. On View B, you can see the vertical quick-connects plugging into the core, then the large loop of rubber hose terminating in those wide crimps (a dremel works great, just be careful not to go too deep). Everything else in that diagram is just aluminum tube running forward. A couple more feet and you'd see the next section of rubber hose right behind the front wheel, which bends inward to the frame-hole-connects.

Hopefully this helps someone at some point. The part numbers are probably the most useful.

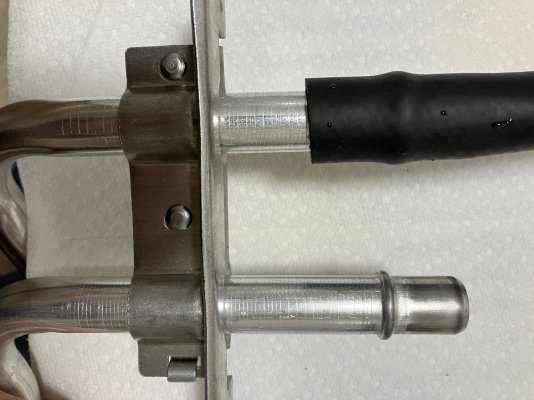

Edit: I forgot to mention, if you do find that front assembly make sure you compare the new to the old after you remove it. The small bracket on my new one was roughly backwards compared to the old one. I didn't compare before trying to install and the bolt hole was like 3" out of position. I removed it again and compared, and realized it was never going to be able to line up so I had to swap brackets. Not a big deal, but a minor hassle. You can see the difference in the photo. Otherwise the fit was perfect.