Big_Red9

Newbie

Hello GMT400 world,

I am a new poster to this website, but I've been scrolling through these forums for the past ~6 months. After putting countless hours into my newly acquired '97 Suburban, I figured it's time to finally post the issues I've been battling with in lieu of going to a mechanic.

I'll begin with what my problem is: I have been consistently getting a P0420 code thrown (Catalyst System Efficiency Below Threshold Bank 1) as well as other related codes occasionally such as P0131 and P0151. I know this is an indication to replace my cats, but what I am trying to figure out is WHY they went bad. I will also add that if I am driving under heavy load (******* it up a hill) I'll feel the engine missing and usually that's followed by a flashing P0300. This has lead me to believe that I ruined my cats because my engine has misfired many times.

Here is what I've done so far (I will probably forget some things too):

- New plugs/wires

- New distributor cap & rotor

- New coil and module

- New cam/crank shaft position sensors

- Inspected distributor gear; looked mint

- Timing test; timing was good

- Cat temp test; did not read any major temp difference upstream & downstream of cat after driving for a while

- Fuel pressure test on the fuel rail; ~60 psi while driving and held steady through various driving ranges

- Compression test; all cylinders were the same around 170 psi

- Smoke test; no vacuum leaks

- Intake vacuum pressure check; took the brake booster line off and vacuum met criteria outlined in Haynes manual (20.5 inHg)

- Etc. you name it, I probably replaced/checked it

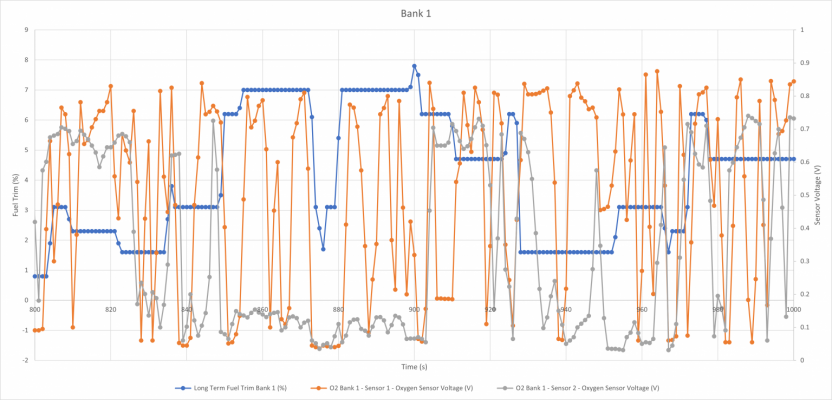

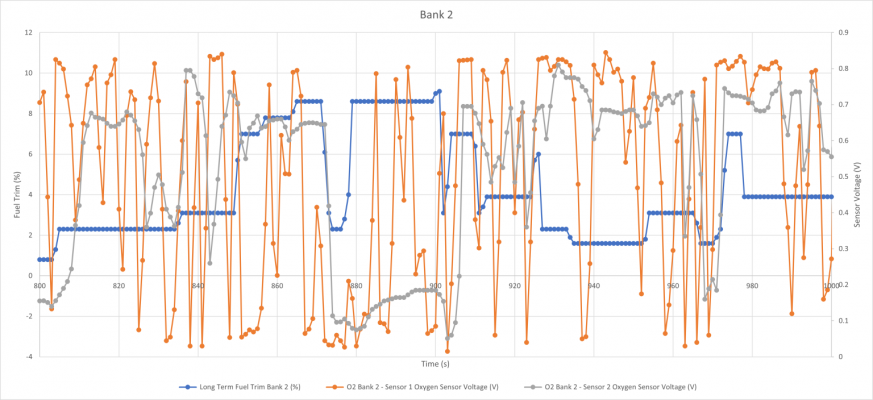

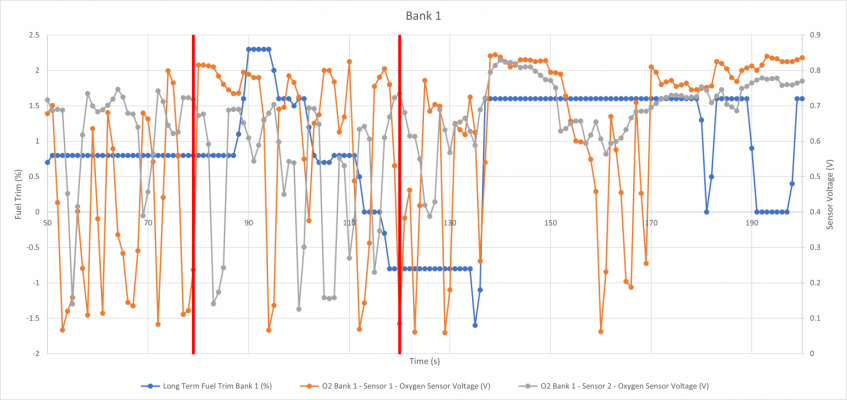

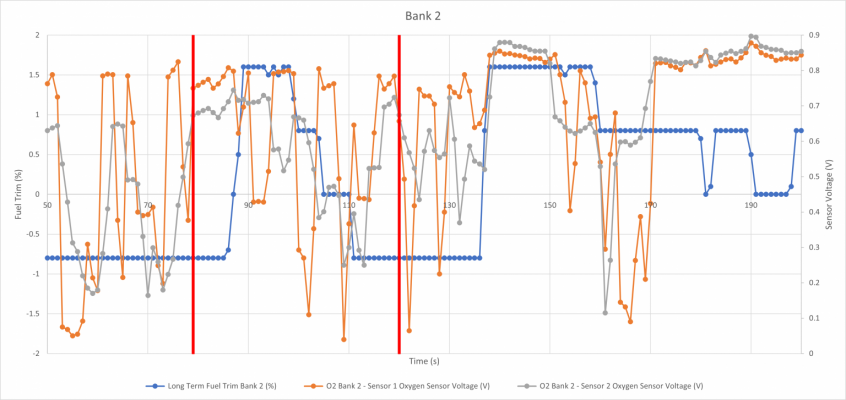

I am done firing the parts canon at it until I really understand what going on here. On my drive into work today, I recorded fuel trims and O2 sensor readings. I'll attach them here - I narrowed it down to a 3 minute snippet of the entire drive just to make it easier to look at, but these snips are a good representation of the rest of the trip.

This is already a long post so I'll wrap it up. It is my understanding that cats don't go bad without some reason. I thought the reason was due to misfires. I can't figure out why it's missing, but I also am not 100% convinced my cats are shot since I didn't seem to have any backpressure on the intake vacuum test and their temp differences were not significant. So what da heck is goin' on?? Any help will be appreciated.

I am a new poster to this website, but I've been scrolling through these forums for the past ~6 months. After putting countless hours into my newly acquired '97 Suburban, I figured it's time to finally post the issues I've been battling with in lieu of going to a mechanic.

I'll begin with what my problem is: I have been consistently getting a P0420 code thrown (Catalyst System Efficiency Below Threshold Bank 1) as well as other related codes occasionally such as P0131 and P0151. I know this is an indication to replace my cats, but what I am trying to figure out is WHY they went bad. I will also add that if I am driving under heavy load (******* it up a hill) I'll feel the engine missing and usually that's followed by a flashing P0300. This has lead me to believe that I ruined my cats because my engine has misfired many times.

Here is what I've done so far (I will probably forget some things too):

- New plugs/wires

- New distributor cap & rotor

- New coil and module

- New cam/crank shaft position sensors

- Inspected distributor gear; looked mint

- Timing test; timing was good

- Cat temp test; did not read any major temp difference upstream & downstream of cat after driving for a while

- Fuel pressure test on the fuel rail; ~60 psi while driving and held steady through various driving ranges

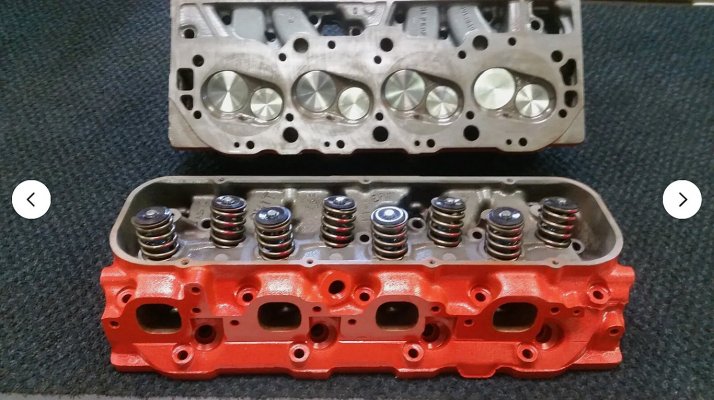

- Compression test; all cylinders were the same around 170 psi

- Smoke test; no vacuum leaks

- Intake vacuum pressure check; took the brake booster line off and vacuum met criteria outlined in Haynes manual (20.5 inHg)

- Etc. you name it, I probably replaced/checked it

I am done firing the parts canon at it until I really understand what going on here. On my drive into work today, I recorded fuel trims and O2 sensor readings. I'll attach them here - I narrowed it down to a 3 minute snippet of the entire drive just to make it easier to look at, but these snips are a good representation of the rest of the trip.

This is already a long post so I'll wrap it up. It is my understanding that cats don't go bad without some reason. I thought the reason was due to misfires. I can't figure out why it's missing, but I also am not 100% convinced my cats are shot since I didn't seem to have any backpressure on the intake vacuum test and their temp differences were not significant. So what da heck is goin' on?? Any help will be appreciated.