I got to the autostore today and replaced the eye connectors on both of the intake manifold ground, immediately high idle seemed to calm down and smoothen out, still seems a little sluggish though when warmed up, tomorrow I’ll probably test the o2 voltage, and I think my throttle cable might be loose (it’s adjustable) so I’ll check that aswell, any idea what voltage the 02 should read with engine running?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hey Guys I Need Help Quick

- Thread starter Nick88

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Oh, now I get it. You're asking about the same problem on the same car on thirdgen.org.

Advice is the same. You need a scan tool.

Advice is the same. You need a scan tool.

0.5V is stoich ie correct mixture (for complete combustion of both fuel and oxygen). Below 0.5V is lean, above, rich.any idea what voltage the 02 should read with engine running?

0.5V is stoich ie correct mixture (for complete combustion of both fuel and oxygen). Below 0.5V is lean, above, rich.

Building on this ^^^ …

At idle RPM, in closed loop, O2 voltage will drift above 0.5v (e.g., ~0.8v) and below 0.5v (~0.3v) for perhaps 1s or longer, as the ECU slowly varies the fuel delivery to match stoich.

If you’re using a DVM, use the DC scale to monitor O2 voltage and watch for this behavior.

At higher RPM this oscillation above / below 0.5v occurs faster and may not be evident on a DVM… it may simply look noisy, although still in the ~0.3v - ~0.8v range.

Yeah lol that’s me Schurkey, I was posting on there too trying to get TBI adviceOh, now I get it. You're asking about the same problem on the same car on thirdgen.org.

Advice is the same. You need a scan tool.

Thank you I’m gonna test it in a little bitBuilding on this ^^^ …

At idle RPM, in closed loop, O2 voltage will drift above 0.5v (e.g., ~0.8v) and below 0.5v (~0.3v) for perhaps 1s or longer, as the ECU slowly varies the fuel delivery to match stoich.

If you’re using a DVM, use the DC scale to monitor O2 voltage and watch for this behavior.

At higher RPM this oscillation above / below 0.5v occurs faster and may not be evident on a DVM… it may simply look noisy, although still in the ~0.3v - ~0.8v range.

Drove truck around just now for a bit to warm it up good, drove like a slug, just backbladed it and highest i could get is . 3 volts, lean i suppose, should I replace the o2 and probably connector, or is something else causing this???

warrantied old o2 for a new one, definitely gonna get a delco one asap, thr new o2 seemed to help a lot though, truck was taking off and getting up to speed like a breeze, i noticed though when i got home the truck has that weird low rpm under load stumble, any idea whats causing that? It has new pump and regulator that hold 11.5psi and i tested under load when i instlaled them and it kept good pressure so im not sure on that

any idea what voltage the 02 should read with engine running?

Drove truck around just now for a bit to warm it up good, drove like a slug, just backbladed it and highest i could get is . 3 volts, lean i suppose, should I replace the o2 and probably connector, or is something else causing this???

warrantied old o2 for a new one, definitely gonna get a delco one asap, thr new o2 seemed to help a lot though, truck was taking off and getting up to speed like a breeze,

Greetings Nick88,

Glad to hear that you are making progress by replacing the O2 sensor. I was getting ready to reply that the

only time I've personally had any luck with troubleshooting an O2 sensor with a DC voltmeter reading was when

the heater circuit was open, either sensor or wiring. (And you aren't running a heated O2 -- at least stock.)

But when it came to the actual signal, if the O2 wasn't bad enough to throw a code I normally couldn't come up

with a good answer via the voltmeter alone on the sensor's output signal? For what it's worth, here's an

actual example of a O2 waveform in action on a TBI vehicle:

You must be registered for see images attach

(credit: google search for TBI O2 waveform)

Schurkey and others will refer to the crossing counts to help determine how good/how lazy your sensor is.

Crossing counts is normally defined as how many times the signal crosses over the 0.5v (14.7:1 stoich) level

per second. The faster the better, but it typically varies from ~1 at idle to 5+ times per second on the highway.

And since you don't have a heated O2 sensor, while sitting at a long stop light the sensor may cool off enough

that your engine reverts back to 'Open Loop' operation until you get going again.

As mentioned previously by the talent, the quickest/easiest way to troubleshoot all this is by having

the computer tell you what it's perception of reality is by looking at the live data. Of course this means

having something capable of this in your hands in 2024 that can graph data from a '88 vintage computer.

(I don't know what the definitive list of advanced functionality scanners that can do this is, but I'm sure that it's a short one.)

i noticed though when i got home the truck has that weird low rpm under load stumble, any idea whats causing that? It has new pump and regulator that hold 11.5psi and i tested under load when i instlaled them and it kept good pressure so im not sure on that

I went through your list of repair parts in this thread, but did not see any mention of the following?

Ignition:

* spark plugs

* spark plug wires

* cap, rotor, coil

Also, especially when low rpm stumble is mentioned:

* EGR valve?

* Knock Sensor?

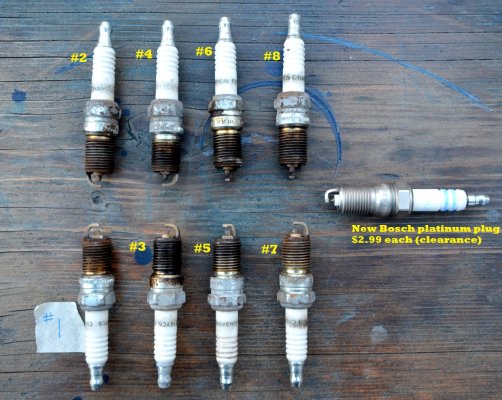

I'm not advocating for the parts cannon, but especially after your gas mileage dropped down to

5 mpg, it's possible that your spark plugs are all carboned up, making misfiring/misbehaving under

low rpm load much more possible to stimulate?

If you were pull a plug and check the color this would be helpful. And if they have a bunch of miles on

them then consider using this episode as an excuse to replace them all with some fresh ones. (No need

to spend a lot of money, they are easy to get to and you're running a .035" gap.) NOTE: If you do

change them out, then take a group photo, organized exactly as they come out of the engine, and this

way we could look for trends. (ie: spark plugs/cylinders fed by left injector pretty, but plugs fed by right

injector very dark/rich, etc.) FWIW, I've attached an example of what I pulled out of my chore truck so

you can see what I'm looking for.

Of course if your truck is already on the mend then you don't need to pull the plugs for me. Your call. But

if the low rpm misbehavior persists then we do need to give the plugs a look for some old-school troubleshooting

hints.

****

Even though you currently don't have a OBD1 scanner capable of graphing live data, you do have en embedded

diagnostic function in your TBI computer that, with a little practice on your part, will allow you to see the air/fuel

ratio that the computer has figured out (right or wrong) based upon the signals it's getting from your O2 sensor.

If you already know how to retrieve the TBI's check engine light codes (paper clip on the 2 pins in the ALDL connector)

during KOEO (Key On Engine Off) then you already know how to get into Field Service mode. Just leave the 2

pins jumpered, start the engine, and as soon as the O2 sensor warms up you will see the fast Open Loop flashing

switch to the slower Closed Loop mode. See the attachment from the FSM where they describe this diagnostic

feature. After reading that, if this piques your curiosity, then follow this link where another member of the forum

actually shared a video of what he was seeing: (TBI SES light in Field Service Mode, unhappy engine demo)

And if you watched the video and the light flashing looks to be semi-random, in actuality there was valid data

being shown. Over here is what I interpreted from that video after reading the FSM description: (graph of Open Loop

vs Closed Loop vs Duty Cycle)

Being perfectly honest, once you get your ride back to the old (good) gas mileage I'd like to see if your vehicle reverts

to the 50/50 duty cycle. (translated: I don't own a TBI truck, but I'd really like to verify the Field Service mode

functionality for similar troubleshooting sessions w/others.)

Anything you could share on what you are seeing would be appreciated. The more hands-on data like this the

stronger the troubleshooting base that we are all working from. (!)

****

To recap, your engine going from good to bad suddenly could definitely be explained by an O2 sensor going

bad. It will be interesting to see what happens from here. As for the stumble under low rpm load, this may

be a temporary hangover from the plugs getting carboned up during the recent too-rich operation. If the

plugs are newish, then maybe an old-school Italian tuneup will clear the fault? Or if the plugs were ready to

be changed anyway, possibly use this an excuse for a fresh set of plugs...and take a photo of the old ones

and post them here? And if you wish to pursue an answer as to whether or not your computer + new O2

sensor is getting the Closed Loop A/F ratios right, then possibly drive around with the ALDL pins jumpered?

Let us know what you discover. Real world results are a big help in upping our game at this remote

troubleshooting thing over time.

Best of luck.

PS - Part of the reason why I jumped in was that for about a year I owned an '88 K5 Blazer with a 350/granny

4-speed, and I miss it mightily. Anything I can do to help keep one of those on the road feels right. :0)

Attachments

Last edited:

Hey sorry I couldn’t reply sooner, but the cap rotor, coil, plugs, wires, are all brand new 1000-5000miles max on each, last night I unplugged the knock sensor and it really helped, for about 10 minutes then it acted like a slug again with knock sensor unplugged. Still idled kinda funny with it unhooked though. I think I’m gonna try out switching out my new auto zone dura-crap iac later for the factory see if that fixes my idle issues. I’m not sure if the iac would cause lack of power driving around though???Greetings Nick88,

Glad to hear that you are making progress by replacing the O2 sensor. I was getting ready to reply that the

only time I've personally had any luck with troubleshooting an O2 sensor with a DC voltmeter reading was when

the heater circuit was open, either sensor or wiring. (And you aren't running a heated O2 -- at least stock.)

But when it came to the actual signal, if the O2 wasn't bad enough to throw a code I normally couldn't come up

with a good answer via the voltmeter alone on the sensor's output signal? For what it's worth, here's an

actual example of a O2 waveform in action on a TBI vehicle:

You must be registered for see images attach

(credit: google search for TBI O2 waveform)

Schurkey and others will refer to the crossing counts to help determine how good/how lazy your sensor is.

Crossing counts is normally defined as how many times the signal crosses over the 0.5v (14.7:1 stoich) level

per second. The faster the better, but it typically varies from ~1 at idle to 5+ times per second on the highway.

And since you don't have a heated O2 sensor, while sitting at a long stop light the sensor may cool off enough

that your engine reverts back to 'Open Loop' operation until you get going again.

As mentioned previously by the talent, the quickest/easiest way to troubleshoot all this is by having

the computer tell you what it's perception of reality is by looking at the live data. Of course this means

having something capable of this in your hands in 2024 that can graph data from a '88 vintage computer.

(I don't know what the definitive list of advanced functionality scanners that can do this is, but I'm sure that it's a short one.)

I went through your list of repair parts in this thread, but did not see any mention of the following?

Ignition:

* spark plugs

* spark plug wires

* cap, rotor, coil

Also, especially when low rpm stumble is mentioned:

* EGR valve?

* Knock Sensor?

I'm not advocating for the parts cannon, but especially after your gas mileage dropped down to

5 mpg, it's possible that your spark plugs are all carboned up, making misfiring/misbehaving under

low rpm load much more possible to stimulate?

If you were pull a plug and check the color this would be helpful. And if they have a bunch of miles on

them then consider using this episode as an excuse to replace them all with some fresh ones. (No need

to spend a lot of money, they are easy to get to and you're running a .035" gap.) NOTE: If you do

change them out, then take a group photo, organized exactly as they come out of the engine, and this

way we could look for trends. (ie: spark plugs/cylinders fed by left injector pretty, but plugs fed by right

injector very dark/rich, etc.) FWIW, I've attached an example of what I pulled out of my chore truck so

you can see what I'm looking for.

Of course if your truck is already on the mend then you don't need to pull the plugs for me. Your call. But

if the low rpm misbehavior persists then we do need to give the plugs a look for some old-school troubleshooting

hints.

****

Even though you currently don't have a OBD1 scanner capable of graphing live data, you do have en embedded

diagnostic function in your TBI computer that, with a little practice on your part, will allow you to see the air/fuel

ratio that the computer has figured out (right or wrong) based upon the signals it's getting from your O2 sensor.

If you already know how to retrieve the TBI's check engine light codes (paper clip on the 2 pins in the ALDL connector)

during KOEO (Key On Engine Off) then you already know how to get into Field Service mode. Just leave the 2

pins jumpered, start the engine, and as soon as the O2 sensor warms up you will see the fast Open Loop flashing

switch to the slower Closed Loop mode. See the attachment from the FSM where they describe this diagnostic

feature. After reading that, if this piques your curiosity, then follow this link where another member of the forum

actually shared a video of what he was seeing: (TBI SES light in Field Service Mode, unhappy engine demo)

And if you watched the video and the light flashing looks to be semi-random, in actuality there was valid data

being shown. Over here is what I interpreted from that video after reading the FSM description: (graph of Open Loop

vs Closed Loop vs Duty Cycle)

Being perfectly honest, once you get your ride back to the old (good) gas mileage I'd like to see if your vehicle reverts

to the 50/50 duty cycle. (translated: I don't own a TBI truck, but I'd really like to verify the Field Service mode

functionality for similar troubleshooting sessions w/others.)

Anything you could share on what you are seeing would be appreciated. The more hands-on data like this the

stronger the troubleshooting base that we are all working from. (!)

****

To recap, your engine going from good to bad suddenly could definitely be explained by an O2 sensor going

bad. It will be interesting to see what happens from here. As for the stumble under low rpm load, this may

be a temporary hangover from the plugs getting carboned up during the recent too-rich operation. If the

plugs are newish, then maybe an old-school Italian tuneup will clear the fault? Or if the plugs were ready to

be changed anyway, possibly use this an excuse for a fresh set of plugs...and take a photo of the old ones

and post them here? And if you wish to pursue an answer as to whether or not your computer + new O2

sensor is getting the Closed Loop A/F ratios right, then possibly drive around with the ALDL pins jumpered?

Let us know what you discover. Real world results are a big help in upping our game at this remote

troubleshooting thing over time.

Best of luck.

PS - Part of the reason why I jumped in was that for about a year I owned an '88 K5 Blazer with a 350/granny

4-speed, and I miss it mightily. Anything I can do to help keep one of those on the road feels right. :0)

Similar threads

- Replies

- 14

- Views

- 678

- Replies

- 32

- Views

- 4K

- Replies

- 12

- Views

- 4K

Members online

- Fluffyfreak505

- JDGMC

- Stumpy

- Drunkcanuk

- bloodshot612

- HolgadoGuitars

- Caman96

- scott2093

- patrick5050

- movietvet

- rzr6-4

- dubless

- amrush2112

- Minn95Dually

- Charlesteneows

- Road Trip

- termite

- 95SUBURBANLM7

- Komet

- SexyRedDad

- JPVortex

- gchavonne

- L31MaxExpress

- jus10inbrla

- Rexall

- S_det

- Laredo

- 0L94fan

- Reaper52

- heskahoka

- 93Chevy93

- kenh

- VIKING_MECHANIC

- Zack8

- tayto

- rhinostacy

- 96stepsideobs

- therealjlove

- chris1371

- Connorpod

- JFanchier

- bingobobby

- the_elegant_fox

- thatguyHoBo

- bluex

- Grooter8824

- 68corvair

- Aaron Poston

- johnckhall

- Sofaree

Total: 1,839 (members: 70, guests: 1,769)