Any ideas why the truck ran so good for a bit with knock sensor disconnecEd then ran like crap again after 10 minutes of it disconnected?

Nick88,

Upon further digging I think that I may have been giving the 'TBI-era' ECM too much credit? As in,

thinking that the older/slower technology TBI computer is running the more complex '96+ Vortec-era'

KS check algorithms?

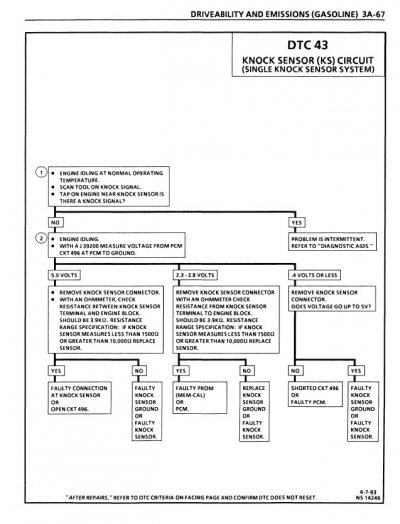

To be more accurate, let me quote a TBI-era FSM on the KS check:

You must be registered for see images attach

So many people look down upon on the inherent simplicity of the TBI design. I happen to subscribe to the notion that

simplicity is the sign of good engineering.

Anyway, to improve the signal/noise ratio, instead of just having the Knock Sensor feedback signal rise up from 0 volts, the engineers

instead have set up a voltage divider network, where the +5v reference signal is sent from the computer to the Knock Sensor.

And thanks to an internal 3900 (3.9K) ohm resistor, this results in a steady mid-range value of 2.5V DC.

And then the actual Knock Sensor feedback signal (similar to a microphone output) AC dances on top of the steady 2.5V DC voltage.

By doing the above, this also allows the engineers to be able to detect an Open Circuit (at/near +5v reference) or a Short to Ground.

(at/near 0 volts) Re-reading the above, it looks like >4.3v or <.64v is supposed to set/store the DTC 43 code. (!)

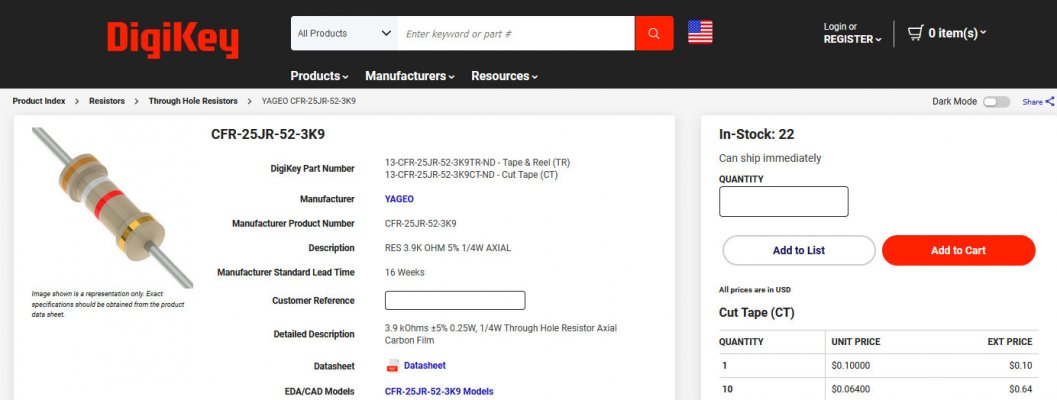

Check this out. For the affordable price of a single 3.9K ohm resistor (see attached) we could temporarily substitute this resistor

in place of the Knock Sensor, which will prevent the ECM from kicking the DTC 43 code and going into the Limp Home ignition timing

mode. So, if by faking the TBI-era ECM to believe that the Knock Sensor is in circuit, and it proceeds to drive right, then we have

identified the Knock Sensor as the root cause of the driveability issue.

I know that I sound overcautious about all this, but I hate the thought of spending other people's money with via a remote diagnosis

parts cannon.

So, in increasing order of confidence, here's the path from here.

* 1) Replacing the Knock Sensor based on the 10 minutes of improved running right after previous disconnection. (promising, but a bit iffy)

* 2) Clearing the ECM memory, getting the bad driveability to reoccur, disconnect the KS a second time, and again this temporarily

fixes the problem. (I'd take this as confirmation, and would personally change the Knock Sensor.)

* 3) Temporarily substituting a 3.9K ohm resistor for the KS, clear ECM memory, and then truck drives nicely for extended periods of time?

I would recommend in public that you change the Knock Sensor.

* 4) Get a Schurkey level dude with a period-correct pro level OBD1 scan tool involved. Take them for a ride-along while monitoring the data.

Do whatever they recommend. (Failsafe approach. :0)

****

Don't know how much electronics background you have. If this isn't in your comfort zone, do you have a zany

buddy who's a sparky type? If so, show him the circuit in the FSM and the resistor listing. If he's good, he may

have one of these resistors sitting in his stash. It's not as Macguyerish as it sounds. It's a simple fake for a simple ECM. :0)

EDIT: I've added the associated troubleshooting tree as an attachment for your sparky type to review. Of

course live data is the best of all, but this gives you an idea of how the General wanted the techs to verify

proper KS circuit operation.

****

One last thing. I'm seeing others recommending timing, vacuum, and compression checks. I'm assuming that

from your previous comments that all this has already been adequately covered. And I know that I won't start

messing around at this level unless I'm at the point where I know that the engine would be running just fine

with a conventional carb & mechanical distributor involved...so I'm just dealing with a 'ECM management' issue?

Apologies for any convolution here, this is a bit hard to explain via the written word from a remote location.

At the very least, run that KS disconnect test a 2nd time (per the instructions above) ...and let's see what you got.

For what it's worth, if everything else is accounted for, then it's starting to smell like a bad KS to me.

EDIT: The only question mark remaining is why no stored codes/steady SES light when the KS was

disconnected? If we decide to replace the KS and the problem remains, then there's the outside chance

that the ECM is starting to flake out due to old age? But given the cost associated with a rebuilt ECM,

I for one will try everything else first and only replace the ECM as a last resort. (Just trying to cover all

the bases for completeness. The 10 minutes of good running gives me hope that you are within a KS

replacement of restoring good behavior in the engine bay.)

Best of luck. Looking forward to seeing what you discover.

Attachments

Last edited: