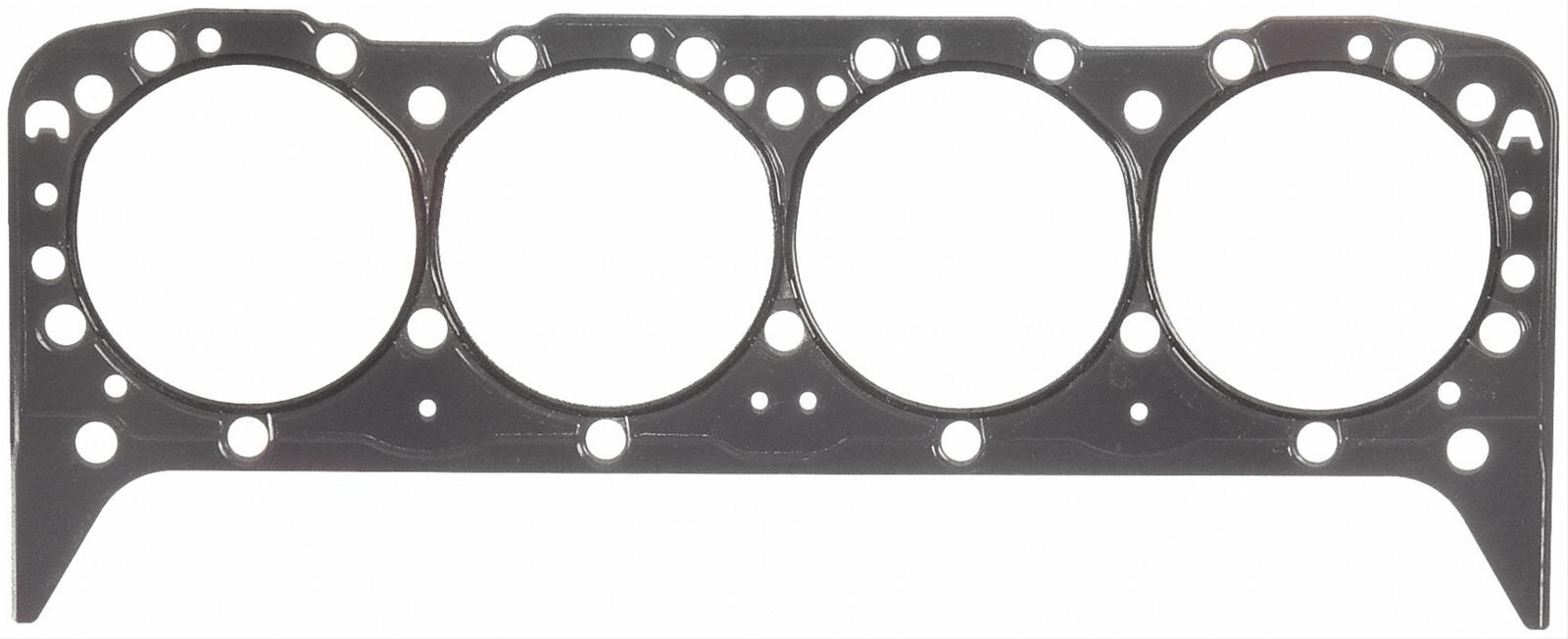

1. Your parts list is...interesting. Ten dollars each for two tubes of ARP sealer? You will not be able to use one entire tube on a two-cylinder-head replacement job. IF (big IF) your existing head bolts are in good condition--not stretched or corroded, for example--REUSE THEM, using that ARP sealer on the threads and some oil or other lube under the heads. Save a hundred dollars. GM head bolts are fine-quality items. Your choice of head gaskets is not optimum. Bore size larger than it has to be, no telling what the thickness is, 'cause it's not listed. Your stock engine has the pistons "in the hole" about .025 already, maybe more. (You should verify.) Mine were about .028. Ideally, a .015 head gasket (thin steel shim gasket) would give you near-perfect quench/squish IF (big IF) the block doesn't need to be decked. If it turns out you need to deck the block, the very thin head gaskets won't work. About the best you can hope for is

Free Shipping - Fel-Pro Performance Head Gaskets with qualifying orders of $109. Shop Head Gaskets at Summit Racing.

www.summitracing.com

as long as the gasket clears the combustion chamber--I'm sure it will. These steel-shim gaskets have a rubbery coating on them, no sealer needed.

Add a container of anti-seize. ANY brand, ANY kind is better than "none". I'm currently favoring Loctite/Permatex "Copper", but I've used 'em all over the previous decades. They all work.

Free Shipping - Permatex Copper Anti-Seize Lubricant with qualifying orders of $109. Shop Anti Seize at Summit Racing.

www.summitracing.com

I would also add a tube of engine assembly lube. Every automotive company on Earth sells their brand of assembly lube. Lubriplate "105 Motor Assembly Grease" is the industry standard. I have a mostly-used-up tube of that in my shop right now.

www.lubriplate.com

However, I also bought a tube of Sta-Lube Moly-fortified engine assembly lube, which I'll begin using when my 105 runs out. And there are liquid assembly lubes, too--but I prefer a grease so it stays where I put it.

xc_hide_links_from_guests_guests_error_hide_media

You'd put a dab of assembly lube on each end of the pushrods, on the rocker-arm pivot balls, on each valve tip where it touches the rocker arm--anywhere there's moving parts making contact that you've disturbed in the process of replacing cylinder heads.

Any fastener that doesn't get oil or moly-based thread lube, or threadlocker, or sealer, gets anti-seize. NO FASTENER gets assembled "dry". And when it comes to flat washers--like those included with the ARP head bolts, you'd lube the underside of the bolt head where they touch the washers, but

NO lube applied to the WASHERS. Lubing the underside of the washer leads to over-torquing and fastener failure. Remember to adjust the torque specs based on the lube on the threads and under-side of the bolt head. The more-slippery the lube, the lower the torque used.

I can't think of anything this job requires that needs threadlocker. You'll probably want a gasket dressing although it's not absolutely essential. My favorite is Gasgacinch; but there's thirty brands and types, and they all work just fine except one. DO NOT use RTV Silicone spread onto a gasket to "seal" it. RTV Silicone is for use ONLY where you aren't using a gasket at all--the cured silicone IS the gasket; or when there's a seam between two gaskets, or between a gasket and a seal. Then a "dot" of RTV Silicone is used only at the seam. For the record, Fel-Pro is likely to include some silicone sealer with the gasket set, if needed. And Permatex "The Right Stuff" is the best silicone-type sealer I've ever used. I'm not sure it's actually silicone. I've heard it's Polyurethane but never been able to confirm.

Free Shipping - SCE Gasgacinch Gasket Dressing with qualifying orders of $109. Shop Gasket Coatings at Summit Racing.

www.summitracing.com

2. $200 is not going to get you headers that will make any difference. Might as well use the stock manifolds IF (big IF) they don't have (obvious or hidden) cracks, and they're not so distorted you can't get them bolted-up again. They actually make manifold spreader tools that you wedge into place, so when the manifold bolts come out of the head, the manifold doesn't warp. And the manifolds will likely need to be planed flat again, too. If the manifolds are smooth and flat, and the exhaust manifold surface of the head is smooth and flat--DON'T USE GASKETS. Bolt the manifold DIRECTLY to the head. Improves heat transfer, manifold runs a little bit cooler. When it was me, I bought shorty headers that connect to the stock exhaust--but that was more than twenty years ago, and they were WAY more than $200 even then. And--truth to be told--they didn't make much difference.

3. Might as well budget for new rocker arms. The ones you have are probably worn-out by now. You can play games with more rocker ratio, with roller tips, and full-roller rockers, but none of that is genuinely needed. The existing rocker arms are "guided" or "self-aligning". Make sure the replacements are, too. Possible you could get by with the existing pushrods, but inspect them carefully for wear and for straightness.

If your new "Performance" heads have

steel pushrod guideplates, you MUST buy hardened pushrods, the stock pushrods will be eaten alive, and you MUST NOT use self-aligning rocker arms.

4. Do these "performance" heads have the

correct intake manifold bolt angles? The center two on each head need to be at a steeper angle than the front and rear pairs.

5. CONFIRM that the valves on these "performance" heads actually seal. There's various hobby-style solutions that generally involve some sort of solvent poured on one side of the valve, and then you look for solvent traces on the other side. An actual machine shop is likely vacuum-testing the valve seal. A vacuum machine is attached to each intake and exhaust port in turn, and the gauge on the vacuum tester shows how close to "perfect" vacuum the machine can generate. There's always some minor leakage past the valve guide, so you'll never see 100% sealing. But 70 percent and better should be fine.

You must be registered for see images attach

Vacuum tester connected to Lumina 3.4L DOHC cylinder head exhaust port, showing 87% perfect vacuum.

The VALVE can be worn-out, burnt, pitted on the valve face, or taper wear on the valve stem, or both. The valve SEAT can be burnt/pitted/eroded, and the valve GUIDE can be worn out. Any one--but it's usually a combination--can lead to poor valve seal. Slapping new valves into worn seats and guides is a short-term "fix".

6. When the intake and heads are off the short-block, pull ONE LIFTER AT A TIME to check for lifter bottom wear. The bottom of "flat tappet" lifters like TBI engines use, is very slightly crowned, like the outside of a contact lens. It should rock slightly on a piece of glass, or a truly flat benchtop (glass preferred.) If the lifter has "indented" wear, like the eyeball side of a contact lens, IT'S JUNK, and SO IS THE CAMSHAFT.

7. Before I pulled the intake manifold off, I'd pop the distributor cap so I could watch the rotor. Turn the crank to TDC in the normal direction of rotation. Then turn it BACKWARDS, as slowly and steadily as you can, while watching the rotor. You'll turn the crank a degree or two before the rotor moves. The instant the rotor turns, stop moving the crankshaft, look on the timing indicator for how many degrees it's turned. 5 degrees or less is good, 10 degrees or more means the timing chain/gears; or the distributor gear is wiped-out. When the distributor comes out, look at the gear--if it's worn excessively (not just "polished"), you need a new one, and if it isn't, you need a new timing set. Between 5 and 10 degrees is kind of a grey area...you "probably" need a new timing set. If you need a timing set, be sure to "degree" the camshaft.

8. As an newbie to engine work, confirm EVERYTHING you do with the Genuine GM service manual; but adjust torque specs as needed based on your choice of thread lubes compared to what GM suggests.

Which aluminum heads did you get? The 162108 ones from Summit Racing I got fit perfectly.

Which aluminum heads did you get? The 162108 ones from Summit Racing I got fit perfectly.