Hi, I've been planning this rebuild for a while now and I'd like a second set of eyes to go over my parts list. I've rebuilt dirt bikes before but this will be my first performace rebuild on a 350 so I'm sure there's some things I need to know.

I have a 1995 K2500 350, with a 5spd (NV4500) and 14 bolt rear end. 150,000 miles on the truck. Its going to be my daily so it needs to have a fairly flat torque curve. I'd like to make 380 ish hp. I don't tow regularly.

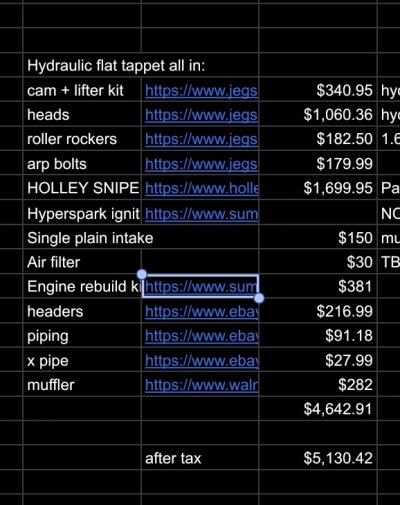

So far my list is this:

Comp Cams Xtreme Energy Hydraulic flat tappet (#CL12-249-4) cam and lifter kit (Lift: .434" /.444" Duration: 249°/260° RPM Range: 1000-5000)

Jegs aluminum heads 195cc intake, 64cc chamber (#555-514063)

Speedmaster Aluminum Roller Rocker, 1.6 Ratio (#746-PCE261100801)

ARP bolts and studs kit

Holley sniper II with full fuel system

Single plain intake (tbd)

Rebuild kit from summit (#SUM-SBCKIT3-311)

Shorty headers (tbd)

3in dual exhaust with X pipe and 2 straight through magnaflow mufflers

Looking at electric water pumps and high output oil pumps aswell (recommendations are appreciated)

From what I can gather this should get me in my desired hp/tq range and run fairly reliability.

Questions:

1. Is the rebuild kit going to fit my stock block and rotating assembly? It says it's meant for pre 86 350s but I cannot find a good complete kit for 90s 350s.

2. Am I going to make the kind of power I want?

3. Will I make this power reliably

4. Assuming I tear my block down and there is not extreme wear, should I still get it decked and honed? I would like to avoid this if possible because I'm already planning on spending alot of money ($5200 give or take after tax). If its something I cannot avoid then how much will it cost me?

Any input is appreciated

Thanks

I have a 1995 K2500 350, with a 5spd (NV4500) and 14 bolt rear end. 150,000 miles on the truck. Its going to be my daily so it needs to have a fairly flat torque curve. I'd like to make 380 ish hp. I don't tow regularly.

So far my list is this:

Comp Cams Xtreme Energy Hydraulic flat tappet (#CL12-249-4) cam and lifter kit (Lift: .434" /.444" Duration: 249°/260° RPM Range: 1000-5000)

Jegs aluminum heads 195cc intake, 64cc chamber (#555-514063)

Speedmaster Aluminum Roller Rocker, 1.6 Ratio (#746-PCE261100801)

ARP bolts and studs kit

Holley sniper II with full fuel system

Single plain intake (tbd)

Rebuild kit from summit (#SUM-SBCKIT3-311)

Shorty headers (tbd)

3in dual exhaust with X pipe and 2 straight through magnaflow mufflers

Looking at electric water pumps and high output oil pumps aswell (recommendations are appreciated)

From what I can gather this should get me in my desired hp/tq range and run fairly reliability.

Questions:

1. Is the rebuild kit going to fit my stock block and rotating assembly? It says it's meant for pre 86 350s but I cannot find a good complete kit for 90s 350s.

2. Am I going to make the kind of power I want?

3. Will I make this power reliably

4. Assuming I tear my block down and there is not extreme wear, should I still get it decked and honed? I would like to avoid this if possible because I'm already planning on spending alot of money ($5200 give or take after tax). If its something I cannot avoid then how much will it cost me?

Any input is appreciated

Thanks