1998 K1500 5.7L. 167,*** miles. I'm wondering what parts to upgrade for motor longevity.

Engine longevity should be a distant second priority. FIRST priority is to verify that the vehicle is SAFE to drive--

steering, suspension, brakes all functioning properly. If the engine fails, you're late for work. If the vehicle doesn't stop, or stay controllable, you maybe kill someone.

Having said that, the ABSOLUTE BEST THINGS you can do to assure engine longevity are:

1. Get several oil-sample kits. Send off an oil sample for lab analysis NOW. If the report suggests problems, fix whatever is needed. Send another after the oil has ~6 months/6000 miles on it. You may find that once-a-year oil changes are perfectly acceptable, and maybe you don't even need to change that frequently. My Trailblazer gets the filter changed at 13,000, oil level topped-off, and I don't change oil until ~26,000 miles--and the oil analysis still says the oil is "fit for further use". But that can change if the thermostat fails, or an injector leaks, or you have some other engine-related failure like leaking intake gaskets. Does oil analysis really work for extending oil-change intervals? I don't really know. That Trailblazer only has 21 years and 280K miles on it with nothing more than replacing the ignition coils and spark plugs, so I don't really know how this is going to work-out long-term.

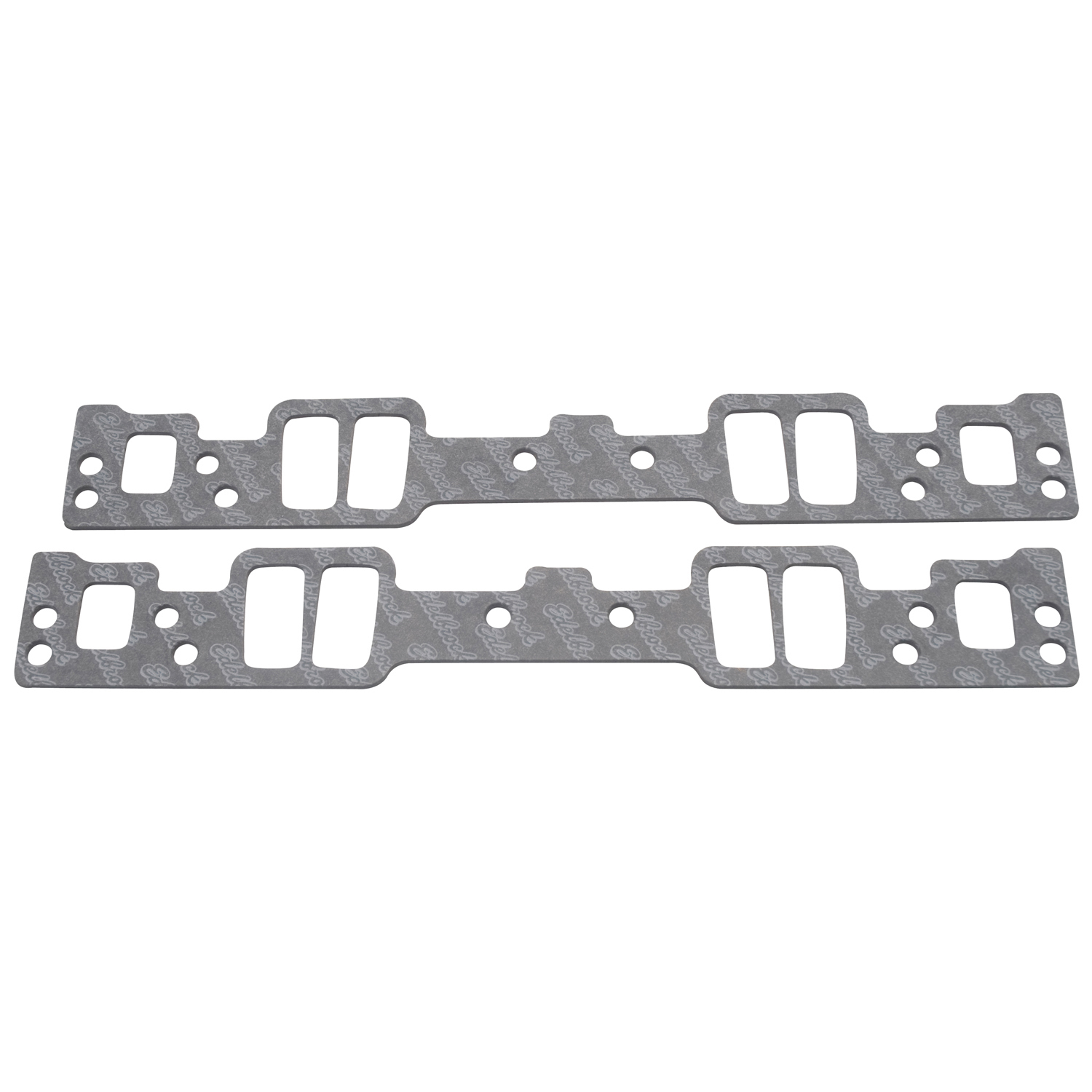

2. Maintain all the usual "tune-up" items in good condition. Cap, rotor, plug wires, plugs, EGR system, PCV system, spark advance, knock sensor system...you get the idea. Vortec engines are susceptible to distributor cap and intake gasket problems. The poppet-style injector spiders are known for failure, generally replaced with electronic injector spiders. O2 sensors, and MAF sensors have an expected service life, they deteriorate in use. An O2 sensor, for example, is questionable after 50K miles, even if it seems to be OK. All the other sensors are good until they aren't. You should probably replace ALL the O2 sensors soon.

3. Buy an aftermarket, bypass oil filter system. Plumb it into the engine oiling system. I get mine used, or NOS from eBay. Amsoil sells "new" ones, as do several other manufacturers. The kind I get--the old SKY-brand "Frantz" toilet-paper filters use a roll of cheap assrag to keep the oil cleaner than new. Filters-out particles as small as what's in cigarette smoke. As long as the filter housing is hot when the engine is fully-warm, it's doing it's job. When the filter housing doesn't get hot any more, the filter is plugged and should be replaced. Often takes years to plug a filter, depending on mileage and driving conditions. The oil, cleaned with the regular filter AND the bypass filter, is good as long as the additive package isn't worn-out--which you learn via the oil-sampling/analysis.

Upgrading is a common misconception. The aftermarket is filled with garbage

Amen!

download the factory service manual and start by changing all the fluids.

...and filters. Consider installing a PS filter. Synthetic fluids are generally preferable to "dinosaur" oils/greases; but better CLEAN, cheap fluids than dirty expensive fluids. MOST "synthetic" oils are not synthetic at all--they're based on plain ol' crude oil, that's been "processed" by having Van Halen played at it at extreme volume levels until it submits. REAL synthetic oil is fairly rare.

Especially important is to flush the brake fluid INCLUDING within the ABS unit, which will

require a scan tool.

The service manual set can be downloaded from links posted in the Sticky section of this forum.

Then, do all the other tuneup and maintenance jobs as needed replacing parts with OEM quality or otherwise the highest quality available.

On a "new-to-me" vehicle, I do an actual inspection of everything I can think of. "As needed" is otherwise determined by when the vehicle fails to get me to where I'm going, or fails to get me home. Better to actively inspect than to find out "the hard way".

But you're right about using quality parts especially for critical systems.

The only known weakness's in the 1500 models are the 4L60e trans starts slipping between 150k - 200k so that might be needed in your near future if it hasn't been rebuilt already. Start saving for that and find a reputable trans shop that is trusted in your community, or swap in a 4l80e.

Yup, the 700/4L60/'60E are weak. Not the only weaknesses, though.

Another known weakness is the 8.5" rear-end. That can be upgraded to a 9.5" from a 6-lug 2500 model.

K2500 6-lug as a donor for a K1500, C2500 6-lug as a donor for a C1500. The C1500s have the additional complication of being a 5-lug axle shaft/wheel while the C2500s have six lugs.

Keep your eyes out for one of those with matching gear ratio as your front diff to swap in at your leisure rather than scrambling to find one when something goes wrong with your unit.

Amen. You'd also be upgrading the rear brakes at the same time, which is HUGELY worthwhile. The original C/K1500 254mm Leading/Trailing shoe rear drums are pathetic. They're perpetually out-of-adjustment leading to a low brake pedal. Keeping them adjusted means using the park brake frequently, and nobody does that so the park brake cables seize.