stutaeng

I'm Awesome

I was talking to my brother the other day about his 90 RCSB and he mentioned something about TC locking up/rpm drop. I honestly can't say that I know when the TC locks on all the trucks that I've owned, but they have all been "E" tranmissions. Last I drove Dad's 89 Sierra was like 20 years ago. ...too young to know about anything, lol.

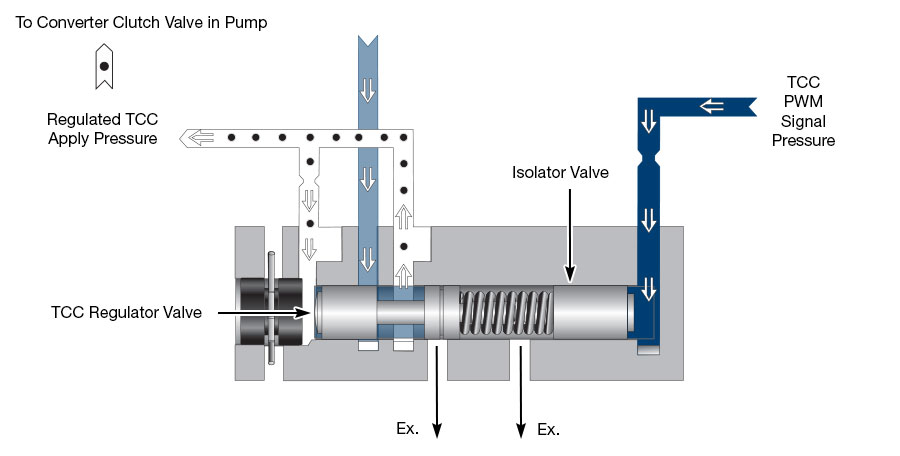

Anyway, why did manufacturers go to PWM? Is it only so that you don't feel the on-off operation? Isn't PWM standard now for all automatics?

And why do guys block off the valve that does this? For durability? Firmness? Would you even block it off for a daily driver with stock drivetrain?

Here's what I'm talking about. At around the 7:45 mark he talks about it...

Anyway, why did manufacturers go to PWM? Is it only so that you don't feel the on-off operation? Isn't PWM standard now for all automatics?

And why do guys block off the valve that does this? For durability? Firmness? Would you even block it off for a daily driver with stock drivetrain?

Here's what I'm talking about. At around the 7:45 mark he talks about it...

xc_hide_links_from_guests_guests_error_hide_media