Just watched your video. Big picture, the engine really seems to be running smoothly.

Since this is the hardest thing to achieve, I don't think that you need to second-guess

your work. To me, a smooth idling engine means that the valves are seating properly.

And this is of key importance, because the only time that the sealing surface of the exhaust

valve gets to cool off is when the valve is firmly seated and conducting heat into the

surrounding water jacket.

In English, you have maximized your Reliability, so most of the pressure is off. But

of course our very next challenge is to figure out are the remaining noise(s) a warning

of trouble down the road? Or is it a minor nuisance that the current assembly of parts

will continue to generate no problem for the next 5+ years?

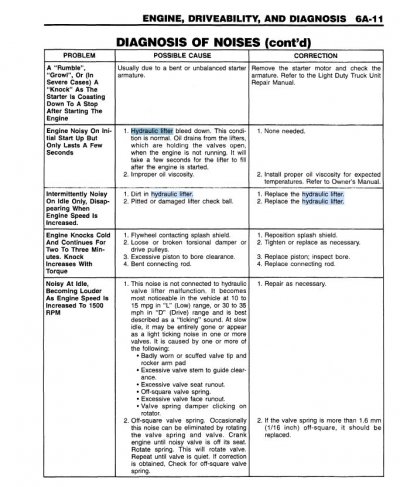

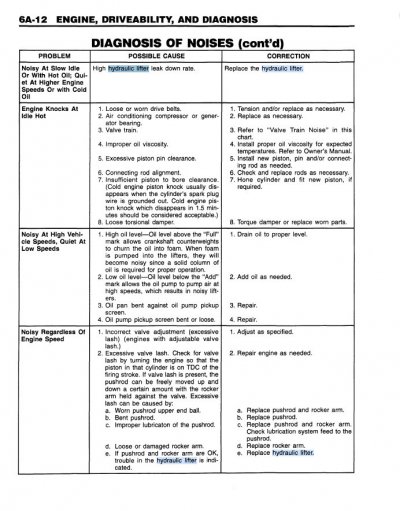

Given this, next in importance to us is how quiet this smooth-running engine is. There

are a *lot* of variables here, since oil pressure varies all over the place. (For example,

@Keeper in reply #89 has a valid point, especially if air got temporarily sucked into the

system due to where the oil pump pickup is vs where your oil in your sump was situated

due to the way you parked?)

I know that I fear most what I understand least. And when I listen to something, I want to

be able to figure out which sounds are normal/forgettable for a specific design, and which

sounds are abnormal and next to be addressed without delay?

****

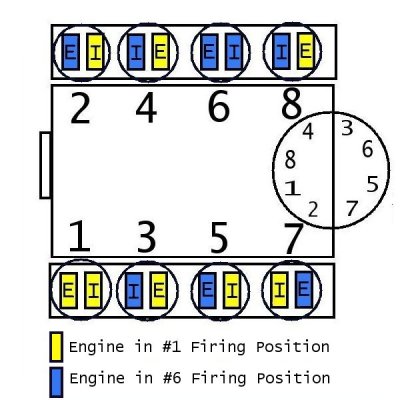

In the next 2-3 replies, I am going to do my best to give a big picture overview of the

various sounds in a adjustable hydraulic lifter valvetrain. Whether or not disturbing

the valvetrain in a long-running engine has put us afoul of internal varnish deposits or

other issues can't really be decided until the following info is read for comprehension.

Since this is the hardest thing to achieve, I don't think that you need to second-guess

your work. To me, a smooth idling engine means that the valves are seating properly.

And this is of key importance, because the only time that the sealing surface of the exhaust

valve gets to cool off is when the valve is firmly seated and conducting heat into the

surrounding water jacket.

In English, you have maximized your Reliability, so most of the pressure is off. But

of course our very next challenge is to figure out are the remaining noise(s) a warning

of trouble down the road? Or is it a minor nuisance that the current assembly of parts

will continue to generate no problem for the next 5+ years?

Given this, next in importance to us is how quiet this smooth-running engine is. There

are a *lot* of variables here, since oil pressure varies all over the place. (For example,

@Keeper in reply #89 has a valid point, especially if air got temporarily sucked into the

system due to where the oil pump pickup is vs where your oil in your sump was situated

due to the way you parked?)

I know that I fear most what I understand least. And when I listen to something, I want to

be able to figure out which sounds are normal/forgettable for a specific design, and which

sounds are abnormal and next to be addressed without delay?

****

In the next 2-3 replies, I am going to do my best to give a big picture overview of the

various sounds in a adjustable hydraulic lifter valvetrain. Whether or not disturbing

the valvetrain in a long-running engine has put us afoul of internal varnish deposits or

other issues can't really be decided until the following info is read for comprehension.

Last edited: