Gotcha, I wasn't exactly sure what you meant, Have used it to do studs,. I know with quite few there are very specific prep procedures/products, some 2 part epoxies have accelerators that can be used for different circumstances etc. Some epoxies I've had luck with some I haven't, some has been OEM labeled so no telling, and have had Reps in the shop doing demos that couldn't get their products work right. Biggest thing I've found with 2 component epoxies is fresh stock. Never had a lot of luck with ones claiming to be able to be drilled and tapped or withstand gas. So I may be just a wee bit biased. Loctite is one of the ones who's stuff generally performs as expected. The metalset might be fantastic stuff and suitable, I'm just a bit gun shy for this situation. if the Op has a means to move the engine being it's out, I'd kinda make some phone calls, visit the local vo-tech, Instructor may be willing to use it as a lesson/demonstration of real world application, and cost very little.

You made some good points about having to Trust, But Verify *everything* that is more complicated than

rock, paper, scissors these days. For example, prior to Covid if I purchased some 2-part epoxy it just worked.

Now, in the past couple of years I've bought 2-part epoxies that didn't even set

up correctly? As it turned out, due to the supply chain issues I was buying old shelf

stock, and the chemicals were too old to work correctly? Personally, I've gone from

blind faith in good epoxy to the 'I'll believe it when I see it mindset.' It's incredible,

for anymore when I'm talking to someone I feel compelled to completely hedge my

bets when it comes to buying 2 different items and having them interoperate as advertised?

Anyway, I agree that Loctite is still pretty reliable, and JB Weld still seems to work. (As long

as I don't buy it in a store where the product is covered in 1/8" of dust. :0)

Speaking of trusting stuff, I did a little more pondering on

@Majoraslayer 's situation, and

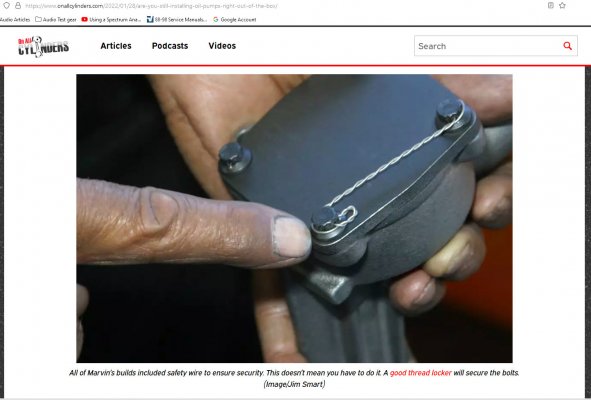

I think I've actually come up with a little more insurance. You see, on military aircraft we

had all manner of hardware that absolutely could not vibrate loose in flight, and even the

most careful of torquing didn't provide enough of an insurance policy. So I'm going to

propose that he safety wire the nut on the stud to the nearest bolt head on the spider, in this

manner:

You must be registered for see images attach

@Majoraslayer, conceptually safety-wiring is easy to understand. In order for one fastener to loosen,

it is physically wired to a sister bolt in such a way that the sister bolt will have to be

tightened for the loosening to occur. (!)

And vice versa. This way, both bolts are physically hardwired into a perfect mechanical standoff. For what it's worth, this method

has never, ever let me down.

So, clean threads > Loctite prep > install new stud > install nut & torque to 18 ft-lbs > safety wire nut

to nearest spider bolt > Enjoy.

Don't give up. Stop, regroup, re-attack. If you've chopped down the Money Tree, stop & lick your wounds while waiting for the

tree to grow back from the roots. :0)

Remember, Quality is the Constant, and Time is the Variable.

If you have any further questions, don't hesitate to ask.

Cheers --