SinCity3500

Newbie

First, apologies if my question have been answered, but looking for the expertise of this forum.

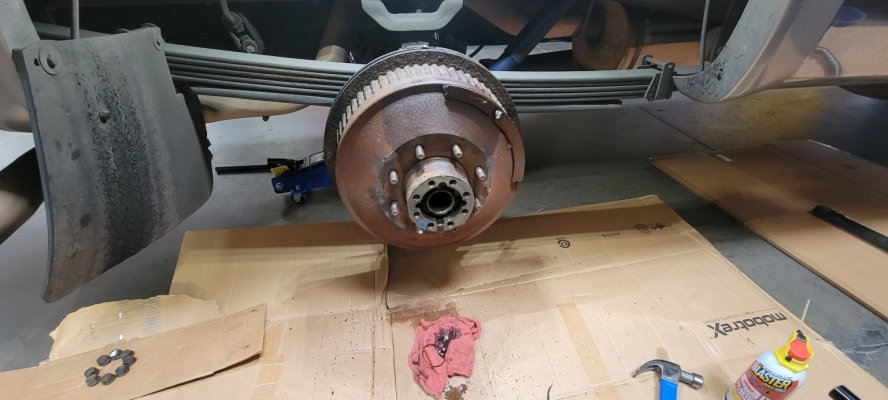

Are the wheel hubs supposed to come off with the brake drums? It seemed to be the only way to get the drums off (along with the axle). I bought new drums, and they don't have the hubs, and now I have no idea how to get the wheel hubs out of the brake drum.

Also, how long are the rear wheel hubs supposed to last?

Finally, it seems there are weights welded to the drum? Is that normal and should I consider trying to save the drums?

Pictures for reference

Are the wheel hubs supposed to come off with the brake drums? It seemed to be the only way to get the drums off (along with the axle). I bought new drums, and they don't have the hubs, and now I have no idea how to get the wheel hubs out of the brake drum.

Also, how long are the rear wheel hubs supposed to last?

Finally, it seems there are weights welded to the drum? Is that normal and should I consider trying to save the drums?

Pictures for reference