Thanks, folks. I appreciate it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First real test drive today, after V8 swap.

- Thread starter DeCaff2007

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

DeCaff2007

I'm Awesome

Schurkey, Road Trip, Hipster, L31MaxExpress, and PlayingwithTBI (to name a few) have all spent tons of time over the course of all your posts trying to help you. Do you think they would steer you in the wrong direction?

No, of course not and my reaction to most posts has nothing to do with that.

It's because there shouldn't be a need to connect a frikken computer to a vehicle this old to find the problem. I have a problem with the concept, not the persons.

I did order that ALDL cable. I've downloaded the software... I even looked up a YT video for an idea of what to expect from that TunerPro RT thing.

If, when this is all said and done, and have perhaps learned nothing from it, I hope it becomes clear why I'm so stubborn about connecting computers to older vehicles.

But, I digress. It's below freezing, the RCSB is covered in a foot of snow, and my mood in general is just BLAH at the moment.

THERE'S A BRIGHT SIDE TO THIS! When the Wife and I attempt to LS swap my 83 Grand Prix, none of that is within the scope of this forum, so you all won't be hearing about that cluster F.

From 1980 1/2 to now, if you can't communicate with the computer(s), you're making guesses. Wild guesses, educated guesses...but guesses. And you're missing out on heaps and piles of information that can help you make sound decisions--and that info is EASILY OBTAINED with minimal time invested.there shouldn't be a need to connect a frikken computer to a vehicle this old to find the problem. I have a problem with the concept, not the persons.

It's like saying, "I shouldn't need to connect a dwell meter or use feeler gauges to set points". Yeah, kinda true. You could use a matchbook cover like Grandpa did. It should get the engine running. May not be as accurate as it could have been, and it takes longer than watching a meter while turning a 1/8" Allen wrench.

"I don't need a timing light to adjust my distributor!". True, you can approximate initial timing with a test light connected to the points. You're gonna have no idea if the vacuum advance has the correct amount of advance, or if the centrifugal springs have gotten too weak...but you can set the initial advance within a couple of degrees.

"I don't need measuring tool to rebuild my Rochester carburetor". Yeah, eyeball float level and float drop. Take a guess at the choke pulloff distance--or just leave it the way it was and hope for the best. Estimate idle speed, and listen for highest idle when playing with the idle mixture screws.

Intuition and experience goes a long way with automobiles. But there comes a time when hard data is faster, easier, and catches things you'd have missed.

Last edited:

It's because there shouldn't be a need to connect a frikken computer to a vehicle this old to find the problem. I have a problem with the concept, not the persons.

Hello DeCaff2007,

I was intrigued by your comment about "the need to connect a frikken computer to a vehicle this old to find the problem."

Because I think that are many people out there who share a similar perspective. But since I am actually old enough

to have fixed stone age style on pre-Closed Loop engines (and got away with it) I'd like to explain all this from a slightly

different perspective.

THE PRE CLOSED LOOP UNDER COMPUTER CONTROL ENGINE TROUBLESHOOTING

* Through the '50s, '60s, and '70s the only computers in the car were mechanical ones.

The camshaft set the firing order and what rpm range that the engine was designed to run in.

And the carburetor determined the Air/Fuel ratios through a variety of overlapping systems.

(main venturi/jetting/air bleeds, accelerator pump, metering rods or power valve, secondaries, choke system.)

And the only real feedback loop was where the vacuum advance on the distributor and the spring-loaded

metering rods in the carburetor would 'monitor' the intake manifold vacuum in real time and infer the

'load' on the engine, and vary the delivery of spark advance & A/F ratios accordingly.

Important: Other than those 2 items, the engine operated in a OPEN LOOP mode. A good mechanic

could observe the symptoms, make necessary adjustments to the appropriate side of the triad (Spark, Fuel, Compression)

and get the engine back to running correctly. It's important to remember this Open Loop concept,

for as a troubleshooter everything makes sense, and you aren't fighting another entity for control

over what's going on under the hood. (!)

THANKS TO EVER-TIGHTENING EMISSIONS, THE ENGINE BAY EVOLVES INTO CLOSED LOOP COMPUTER CONTROL

So back in the good ol' days, let's say that I'd get the chance to check/adjust

the state of tune in your engine bay once every 12 months, for you were better than the

average car owner when it came to keeping your car in a good state of tune.

But with the mechanical points wearing, the carb float that would take on fuel and change

the level in the fuel bowl, accelerator pump cup wear, the spark plug gaps opening up, and a bunch of

other reasons, as time wore on the tuneup went away, with performance drooping and emissions

skyrocketing. Compared to today, it really was the caveman era of internal combustion.

So why complicate things even more with a computer under the hood? Because even our slower

EFI systems perform the equivalent of my careful adjustments up to 12 times each second.

This is much faster than the old 'once every 12 month' interval of the human-based closed loop tuneup.

(12 x 60 x 60 x 24 x 365 days = up to a theoretical 378,432,000 times more often via closed

loop computer fine tuning, a noticeable improvement.) And some of the newer-generation

ECU/ECM/PCM/VCM/0411/(etc) slice & dice this stuff even faster. The mind boggles.

Or think about this for a moment. I'd put a sharp tune on my buddy's 350, fed by a

Q-Jet and sparked via a HEI distributor with 'the good rotor' upgrade in Kansas City,

elevation 909'. Runs *mint*, he's stoked.

He proceeds to drive it to Denver, the Mile High City. (Elevation: 5,280') Now running a bit

sluggish, not so good. And then on to Colorado Springs, where it runs even worse.

(Elevation: 6,035') He's on a pay phone near the Garden of the Gods asking WTF? And

I'm the bad guy when I tell him that driving up Pike's Peak is not a good idea? (Elevation: 14,115')

But by the time he's zoomed back to KCMO via I-70, everything looks fine, right down

to the spark plug coloring. That's right, back in the good ol' days, 99+% of the carburetors

out there could not compensate for altitude. Of course it was standard practice if you

moved there that you would re-jet your carbs to match the altitude?

Fast forward to our GMT400 vehicles. They got this little widget called the Manifold

Absolute Pressure sensor, and thanks to this none of the above happens. KC to Denver

to Colorado Springs to Pike's Peak, and no issues, your getting a fresh tune up at least

12 times per second, no matter what altitude you find yourself driving. :0)

****

By the same token, there's no free lunch. In exchange for all this tip-top non-stop tuneup,

you have to learn to refer to this as your engine running in 'Closed Loop' (endless tuneup)

mode. Worse, as long as everything is working properly you are living the good life. But if

something goes wrong inside this Closed Loop world, up is down, left is right, something

loose and rattly in the exhaust pricks the ears of the Knock Sensor, which tattetails &

causes the ECU to pull 15 degrees of timing from the spark advance. Meanwhile there's

no SES light or error codes stored, for as far as the computer can tell, everything is working

per design?

...but I digress. The point I'm trying to make is that even in the linear Open Loop days of the

Mayberry RFD era, when it comes to troubleshooting an engine that's running rough, is the

root cause bad sparks, bad carb, or exhaust valves just a little burned because the lash

was set too tight? Or did the head gasket blow between #5 and #7 cylinder? Everything

affects (and acts like) everything else.

And when we add another layer of complexity on top of all this with Closed Loop operation,

now this whole 'everything affects everything else' behavior is now an order of magnitude

more intertwined. Because the computer can and will compensate (tune around) around a failing

component until it can't hide the issue any longer, so that when the humans decide to stop and

fix it, it really is a hard to decipher convoluted mess.

****

So, as someone who has lived through this engine bay evolution, I am here to tell you that the older

the computer, the less that it can tell you what's wrong with itself. There wasn't the processing speed

to both tune the motor 100% of the time AND fully diagnose itself/it's sensors on the fly, the needs of the software

coders were expanding faster than the hardware guys could add additional memory, the emissions standards

were constantly tightening, blah blah blah.

Given all of the above, I can absolutely promise you that in order to troubleshoot your '89 K1500 without using

a wheelbarrow's worth of parts, you really and truly absolutely need a frikkin' computer capable of showing you the live data

in order to finish sorting out your engine bay.

Because, even though your truck is old, it *is* being run in Closed Loop mode. And when it comes right down to it, I can either

perform semi-informed parts guessing with your money, or we can study the captured data, kick around a few ideas, and based on the

sum total of everyone's experience in here we can now figure out how to only change the bad bits. Less frustrating,

more satisfying, less moolah in the long run.

Hope you find the above persuasive.

And remember, the veneer of simplicity is unbroken as long as it's working properly.

But when it doesn't work properly? That's when the underlying complexity breaks through the Simplicity Facade.

:0)

THERE'S A BRIGHT SIDE TO THIS! When the Wife and I attempt to LS swap my 83 Grand Prix, none of that is within the scope of this forum, so you all won't be hearing about that cluster F.

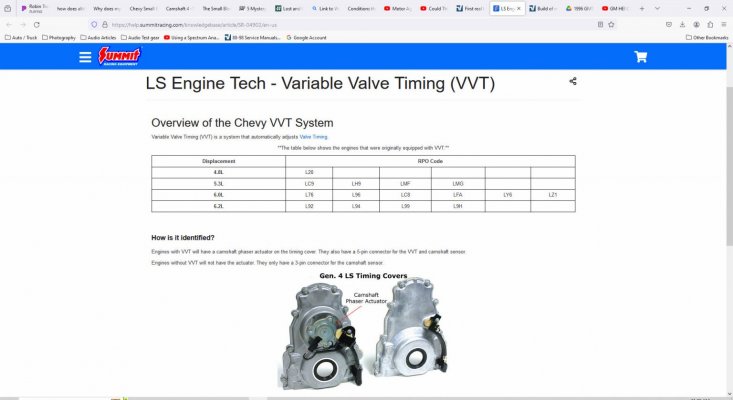

Under EFI control so that you can take advantage of the neat bits like the VVT camshafts? (VVT)

LS motors do amazing things, mostly due to all the newer/faster/better Closed Loop magic involved. :0)

Q: Why not stop and learn the computer stuff on your truck so that when you do that LS

upgrade you can actually look forward to the computer side of the swap?

Food for thought. Apologies for the length. Computers are cool, but they can also be a bit

inscrutable at first glance.

Cheers --

Attachments

Last edited:

DeCaff2007

I'm Awesome

Small update, but not really what anyone wants to hear.

It was a nice day out today, so I took a break from the Wife's Buick (which, is progressing nicely) and decided to take another whack at the RCSB.

I wanted to advance the timing just a few degrees to see if that made any one damned bit of difference. So, I did that and put 5 gallons in the tank.

So, it's now at 8° BTDC. That made the idle happier, now what about WOT? I could feel some power difference. It still feels like something is holding it back. Once the engine gets to operating temperature, those higher RPMs really start to choke. Did I not advance the timing enough? Hmmmm.

HOWEVER, with more gas in the tank, it no longer instantly stalls uphill. PROGRESS. I suppose I should be happy it made it home from the inspection station if it was really that low on gas.

Alright, LAST thing before I connect the laptop/cable/confusing software - I want to check fuel pressure at WOT. What a mistake. The 5/8 steel nut on the incoming fuel is completely stripped out. Not the threads, but the actual nut. Had to use a vice grip to free it from the TB adapter. Then, I sliced my finger open trying to turn it by hand. GRRRR.

Finally got the TBI fuel pressure adapter installed. You guys know: this junk thing.

Turned the key and SPLOOSSHH!! Fuel everywhere, leaking straight from that adapter. Junk.

Alright, so that was the end of that. Next, I'm setting up the laptop. As I'm tightening the adapter that comes out of the TB itself, I hear a crack.

DAMMIT!

At that point, I disconnected the battery and shut the hood. I'm done with this until further notice.

I have other things to do that are just slightly more important than this, and now I find out that I'm likely going to have to have surgery that will screw up most of my summer.

GRRRRRRRRRRRRR.......

It was a nice day out today, so I took a break from the Wife's Buick (which, is progressing nicely) and decided to take another whack at the RCSB.

I wanted to advance the timing just a few degrees to see if that made any one damned bit of difference. So, I did that and put 5 gallons in the tank.

So, it's now at 8° BTDC. That made the idle happier, now what about WOT? I could feel some power difference. It still feels like something is holding it back. Once the engine gets to operating temperature, those higher RPMs really start to choke. Did I not advance the timing enough? Hmmmm.

HOWEVER, with more gas in the tank, it no longer instantly stalls uphill. PROGRESS. I suppose I should be happy it made it home from the inspection station if it was really that low on gas.

Alright, LAST thing before I connect the laptop/cable/confusing software - I want to check fuel pressure at WOT. What a mistake. The 5/8 steel nut on the incoming fuel is completely stripped out. Not the threads, but the actual nut. Had to use a vice grip to free it from the TB adapter. Then, I sliced my finger open trying to turn it by hand. GRRRR.

Finally got the TBI fuel pressure adapter installed. You guys know: this junk thing.

Turned the key and SPLOOSSHH!! Fuel everywhere, leaking straight from that adapter. Junk.

Alright, so that was the end of that. Next, I'm setting up the laptop. As I'm tightening the adapter that comes out of the TB itself, I hear a crack.

DAMMIT!

You must be registered for see images attach

At that point, I disconnected the battery and shut the hood. I'm done with this until further notice.

I have other things to do that are just slightly more important than this, and now I find out that I'm likely going to have to have surgery that will screw up most of my summer.

GRRRRRRRRRRRRR.......

Hipster

I'm Awesome

What forum is the Buick on? I'd like to read through what you referred to as "that cluster f*ck". If nothing else you're good entertainment. Comedy of errors.

DeCaff2007

I'm Awesome

What forum is the Buick on? I'd like to read through what you referred to as "that cluster f*ck". If nothing else you're good entertainment. Comedy of errors.

It's not on any forum, nor any other form of social media.

The cluster f*ck has nothing to do with the Buick. That will be the LS swap I will never get to on my 84 Grand Prix.

Hipster

I'm Awesome

My bad, Pontiac.It's not on any forum, nor any other form of social media.

The cluster f*ck has nothing to do with the Buick. That will be the LS swap I will never get to on my 84 Grand Prix.

You keep mentioning junk tools etc. and are in denial on needing a scan tool. Maybe it's the hand-me-down computer that's junk and needs scanned or you're still chasing melted wires? People can only tell you, they can't understand it for you.

Last edited:

that's because it's metric....Alright, LAST thing before I connect the laptop/cable/confusing software - I want to check fuel pressure at WOT. What a mistake. The 5/8 steel nut on the incoming fuel is completely stripped out. Not the threads, but the actual nut. Had to use a vice grip to free it from the TB adapter. Then, I sliced my finger open trying to turn it by hand. GRRRR.

The thing needs to be chipped/tuned. full stop.

DeCaff2007

I'm Awesome

that's because it's metric....

The thing needs to be chipped/tuned. full stop.

Well, F*CK.

So tell me, when I get a new TBI put on this junk heap, and get the laptop out, and the software going.... and let's say that you're right and it needs to be chipped/tuned.

Fine.

How in the Hell is that going to happen?

Similar threads

- Replies

- 2

- Views

- 308

- Replies

- 22

- Views

- 1K

- Replies

- 6

- Views

- 291

- Replies

- 19

- Views

- 719

- Replies

- 3

- Views

- 271

Members online

- L31MaxExpress

- Orpedcrow

- tayto

- Fredje

- G1kon1wheel

- ali32109

- Trio

- brad007

- Doggy1516

- skeeter21

- Drunkcanuk

- Astro

- BlueLightning19

- Old 96

- Oregonjam

- jimmyve2

- Ivang4342

- F0rdSlayer

- FighterOfTheFoo

- Anchor

- unknwnzz

- Stu925

- Kingsherm

- Zayne8

- Dantheman1540

- Alteca

- Aqua-pig

- Idaho83815

- Carlaisle

- FS68ss

- 99xcss4

- name

- ncnichol

- Tommy1234

- DoctorG

- PM18S4

- Ktrude

- 0xDEADBEEF

- SlamTheMan

- Scorp1982

- 1998_K1500_Sub

- tskaggs9

- PBeam78

- LOW88OBS

- jrodsavvy

- Pcast281

- dads98

- 5vortec7

- Scooterwrench

- yevgenievich

Total: 1,903 (members: 72, guests: 1,831)