Sir,

In order for us to get unstuck on this wiring issue, we have to make the decision to use the very best

electrical wiring harness documentation out there for a GMT400 platform like yours. And based upon serious

data omissions like the one you have discovered, the Chilton Manual simply isn't up to the task. We will need

to set that aside and instead make full use of the '97 Factory Service Manual.

****

Before posting a page from the aforementioned FSM, here's a quick overview of the power layout in the '96+ GMT400s.

1) The battery is the headwaters of the whole shebang. Anywhere from ~600 to 1000 Cold Cranking Amps can be

delivered

instantaneously to a load, and the total quantity of power delivered is limited only by the internal resistance of

the load itself.

And if that load is a wire where the insulation has finally chafed to bare wire against frame, then a serious safety hazard exists.

Not just sparks and fire, but arc-welding levels of power. Serious stuff.

So to help prevent a car fire hazard, a tight web of fusible links, fuses, and even circuit breakers are installed throughout

the vehicle to minimize the chances of you hitting a big pothole & suddenly a chunk of the wiring harness goes up Chernobyl style.

Instead, when a serious short occurs, all that happens is either a fuse, breaker, or fusible link opens, killing the circuit, and

inconveniencing the driver as opposed to what Rainman would definitely put on the 'serious injury' list.

2) As a GMT400 troubleshooter, the good news is that the majority of these safety devices have been concentrated in 2 distinct

locations: The Underhood Fuse/Relay block near the brake master cylinder, and the I/P (Instrument Panel) fuse block

in the cab.

In the Underhood Fuse Block the circuits are mostly powertrain-centric, and also they are ahead of the Ignition Switch,

so they are "Hot At All Times". (And marked this way in the electrical wiring diagrams.) Note that some of the fuses in

the Underhood Fuse Block in turn feed fuses in the I/P fuse block. Please keep this in the back of your mind for later.

Note: There is a variety of fuse ratings in the Underhood Fuse block, but the higher amperage ones will only be found

in this fuse block. And one visual hint that I'm working with a feed from the Underhood Fuse Block is that the 'Hot at

All Times' wires are color-coded

RED.

3) As we all know from living with these machines, a few functions are always available, (Horn, Headlights, dome light, etc)

...but at the same time there are many electrical circuits only available when the driver has enabled their use via choosing

a specific position to turn the Ignition Key.

In turn, most (but not all) circuits in the I/P fuse block are AFTER the ignition switch, so they will be marked as

* Hot in ACC & Run

* Hot in Run only

* Hot in Start & Run

* Hot in Start (only)

And only the smaller fuse sizes and amperages are found in the I/P fuse block. NOTE: Both fuse blocks have overlapping

fuse number locations, so it's easy for confusion to occur when reading the prints. Always double-check to see which fuse

block the fuse is installed in.

And when dealing with "Hot at All Times" wires from the I/P fuse block, they are typically color-coded

ORANGE.

****

I know, we're covering pretty basic stuff in the above, but I want us to be reading the following page from the same

perspective. I've taken the following from the '97 FSM, and here's what Chilton's didn't include:

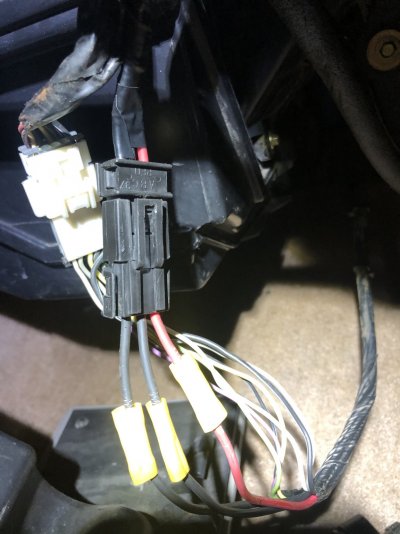

You must be registered for see images attach

(NOTE: MAXI Fuse #7 = BATTERY Fuse thanks to equivalence table previously listed in Reply #

22)

Check out the color coding of all the wires coming out of the Underhood Fuse block.

And then look at the color coding of all the wires coming out of the I/P fuse block.

IF the battery is connected, they are all still 'Hot At All Times', even if the key is out of the ignition.

You know, we often get complacent when working on wiring that's after the Ignition Switch. But

in this area you really need to remember to disconnect your battery before any real wiring harness

maintenance commences.

****

Troubleshooting Time. After all the coloring & sparky-splaining, it looks like the BATTERY fuse in the

Underhood Fuse block fans out to feed the Stop-Haz, PWR ACCY CIRCUIT BREAKER, and T CASE fuses.

With any luck, by pulling these 3 fuses, one of them will remove the parasitic current draw, and then you can

put a tighter focus on the bad circuit. That would be a best-case scenario.

IF the parasitic draw is

still present after these 3 fuses are pulled, then one of 2 scenarios remain:

* A chafe/short condition in Circuit #142 between the Underhood & I/P fuse blocks, traversing

Pin A7 of C100 and splice S200.

* Circuit #142 is OK, but your test light stays on until you methodically depopulate the I/P fuse block and

finally get the light to extinguish. NOTE that it could be more than 1 fuse involved, depending

upon the scope of the wiring error. (This would be a worst-case scenario.)

****

That's all I got at this point. My hope is that you are able to further narrow down this parasitic draw to a

single circuit in the I/P fuse block, and we can then dig further into the wiring diagrams and go from there.

Q: Does this make sense? And if you haven't already done so, please take advantage of the FSMs for

your truck that are a free download over

HERE. Note: The '97 manuals are listed separately in one of

the replies to this thread. It's where I got what I used here.

Let us know what you find.

Best of luck --

EDIT: I've included a clean copy of the '97 Power Distribution page in .pdf format so that you can

easily blow up the details and better follow the wiring diagram during your troubleshooting session.