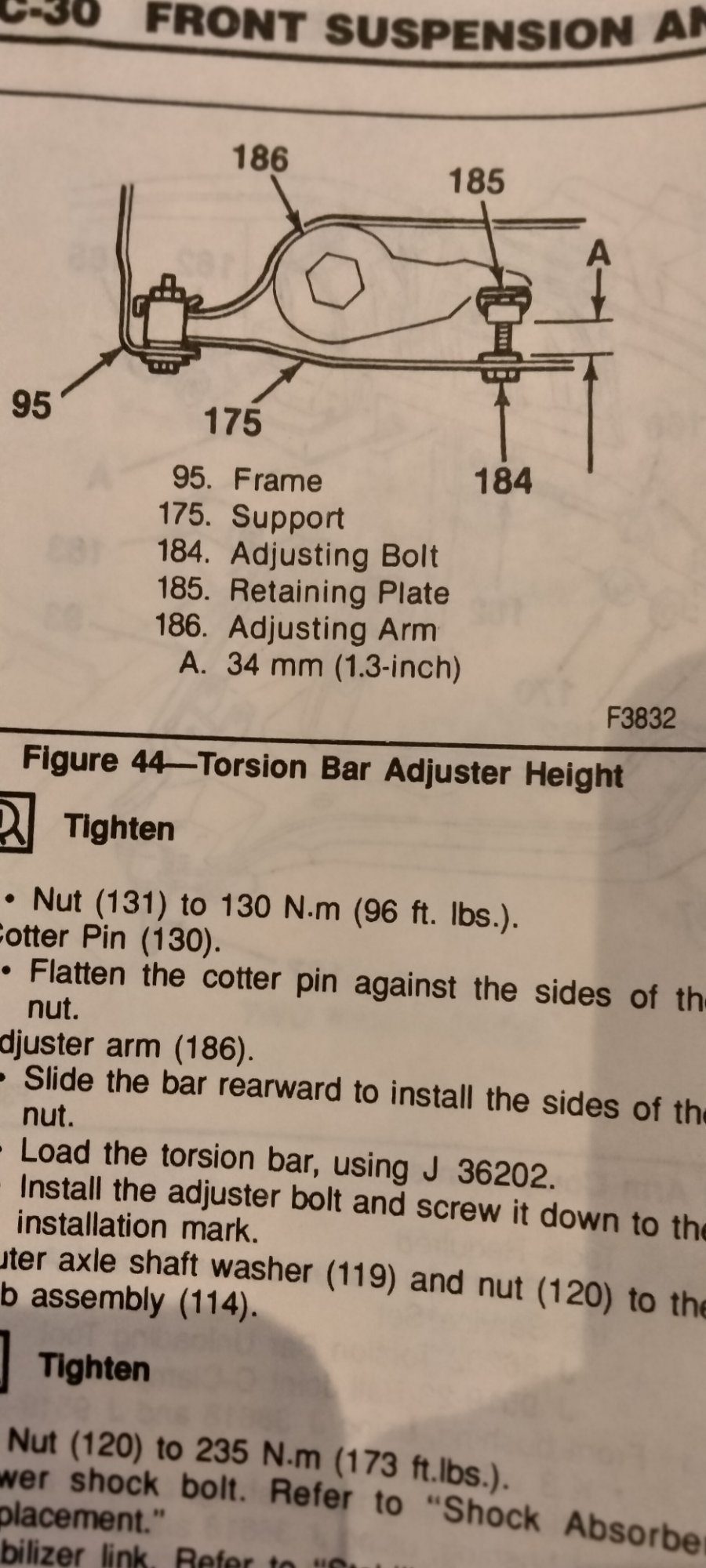

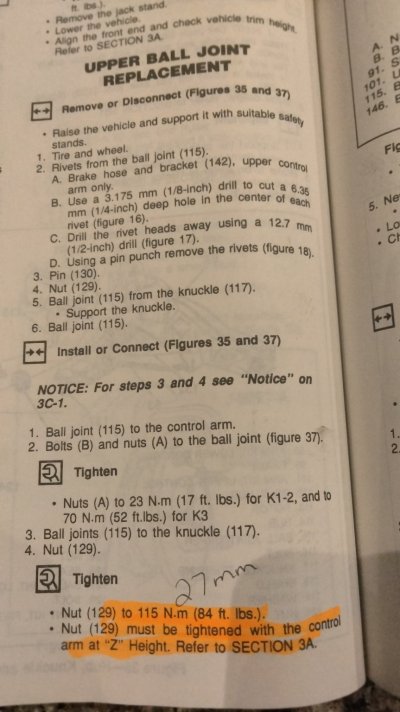

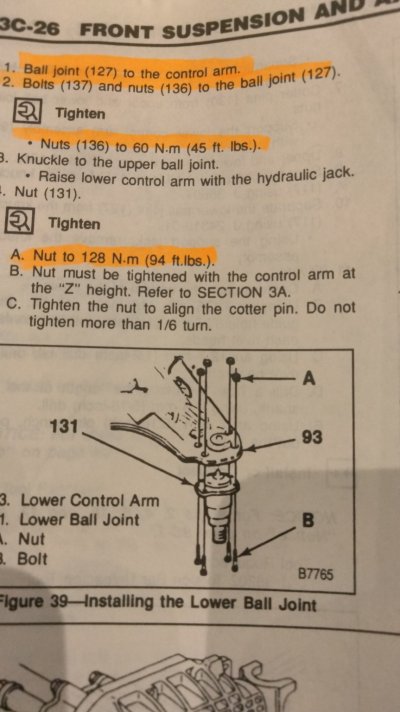

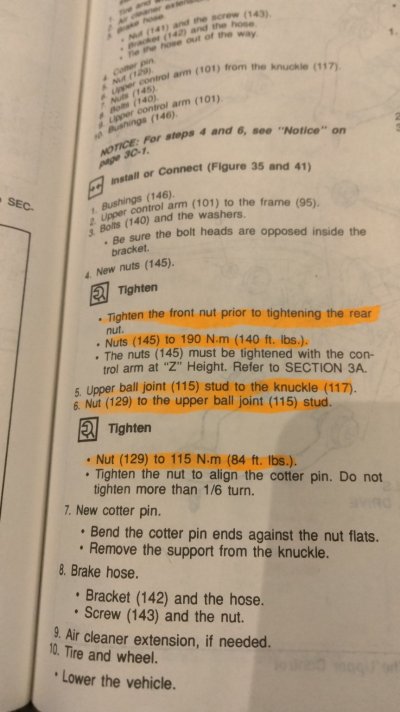

You're supposed to make sure the upper and lower ball joint nuts are tightened at proper z height. As well as both the control arms....

At least on my 93...

Everything mentions jacking up the control arm or whatever to install the nuts (must be installed at proper z height)...then lowering the vehicle... Obviously you can't put the weight of the vehicle when doing the ball joints..

Trying to wrap my mind around the proper way to do it and hopefully it'll spark a memory of how I did mine...

At least on my 93...

Everything mentions jacking up the control arm or whatever to install the nuts (must be installed at proper z height)...then lowering the vehicle... Obviously you can't put the weight of the vehicle when doing the ball joints..

Trying to wrap my mind around the proper way to do it and hopefully it'll spark a memory of how I did mine...

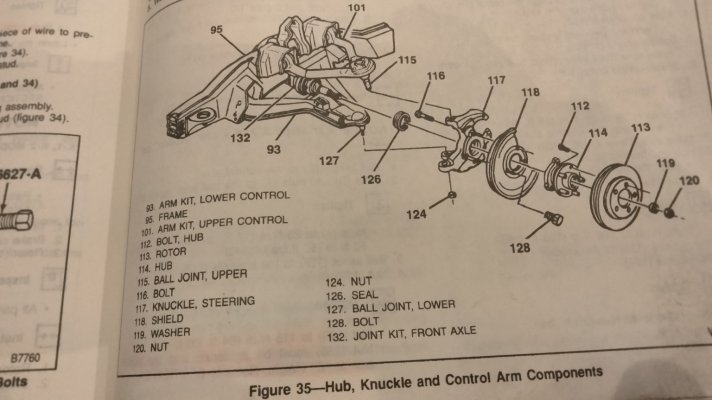

4wd section...)is a few pages back to verify where they came up with that...... And the nut is 124....

4wd section...)is a few pages back to verify where they came up with that...... And the nut is 124....