What can-tap are you using?

US EPA regulations changed the thread-on "Pounder" refrigerant cans (typically 12 oz net weight) so that thread-on can taps for the older cans won't work on the "Self-Sealing" newer cans. I got caught on that when I was working on the Trailblazer A/C. Had to order a new can-tap from Amazon.

But of course there's many suppliers of essentially the same thing.

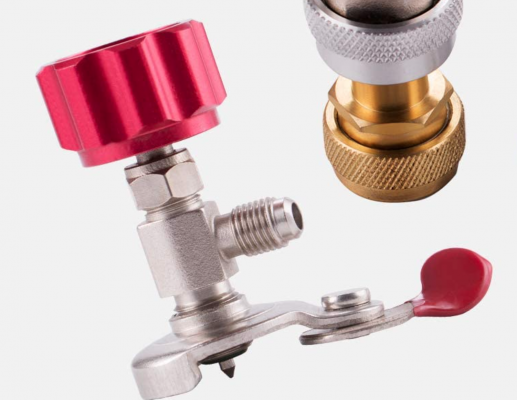

If you're not using the "one-pound" "Pounder" cans, or you're not using thread-on can taps, I don't know what's going on. Do your AC manifold gauge hoses have in-line shutoff valves? Mine do. Did you open those valves?

US EPA regulations changed the thread-on "Pounder" refrigerant cans (typically 12 oz net weight) so that thread-on can taps for the older cans won't work on the "Self-Sealing" newer cans. I got caught on that when I was working on the Trailblazer A/C. Had to order a new can-tap from Amazon.

xc_hide_links_from_guests_guests_error_hide_media

But of course there's many suppliers of essentially the same thing.

If you're not using the "one-pound" "Pounder" cans, or you're not using thread-on can taps, I don't know what's going on. Do your AC manifold gauge hoses have in-line shutoff valves? Mine do. Did you open those valves?

Last edited:

Clearly I was in a little over my head here, though that is kinda how i force myself to learn new things sometimes. Not exactly a textbook perfect install procedure (my fault of course), but thankfully I think things worked out well.

Clearly I was in a little over my head here, though that is kinda how i force myself to learn new things sometimes. Not exactly a textbook perfect install procedure (my fault of course), but thankfully I think things worked out well.