Im back with an update have had the rona and plumbing issues so i am back on the truck.

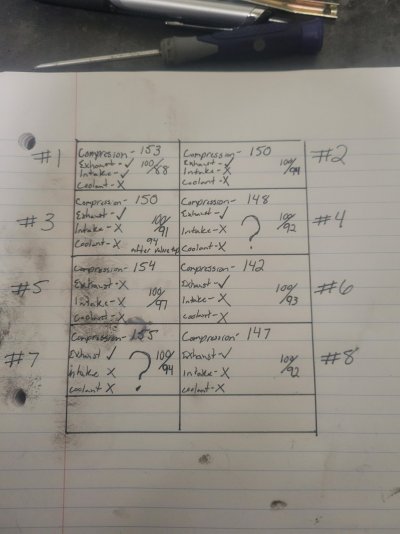

Ive logged all the data i can and ive noticed something weird with number 7 and 4 any time i try too bring the cylinder up tdc the exhaust valves open befor i get there. Ive repeated both of those cylinders numerous times with the same results.

My data below check mark means air heard. X nothing heard.

Hello elevatorman,

I've been pondering your results. At this point, my problem definition is as follows:

* 'Good' compression test results: 142 - 147 - 148 - 150 - 150 - 153 - 154 - 155

* All nearly within +/-5%, median = 150, arithmetic mean 149.8

* Cautionary leakdown test results:

* Good: 7 of 8 cylinders 9% or less total leakage.

* Worst cylinder: (#1) 12% leakage.

Both intake and exhaust valves audible leakage.

* Best cylinder: (#5) 3% leakage. No intake or exhaust valve leaking noted.

* Worrisome: 7 out of 8 cylinders have audible exhaust valve/seat leakage?

* Focused issue: 7 out of 8 cylinders have good intake valve no audible leakage? (#1 is the outlier)

Leakdown testing results analysis:

Perfect leakdown test results are when all 8 cylinders present ZERO audible intake or exhaust

leakage, combined with single digit piston ring/cylinder wall leakage.

Cylinder #5 is the only one to meet this criteria. With no audible valve leakage, then all

leakage is then assumed to be primarily piston ring <> cylinder wall leakage. In unusual

cases piston ring <> piston groove leakage can be the root cause. Stuck/frozen or broken

rings (think motor sitting for a long time in uncontrolled storage) will leak like a sieve.

In terms of total leakage, less than 15% is considered acceptable, less than 10% is good,

and less than 5% for a street motor is excellent.

Using cylinder #5 as an example, your test setup recorded 97/100, which is 3%. (Relative

to itself, not absolute from tool to tool per previous conversations here & elsewhere in the

forum.) But I for one am willing to take this at face value.

I am going to go so far as to say that it looks on balance that you have a combination

of

excellent ring seal combined with marginal exhaust valve sealing, with the #1 intake

valve also failing the check.

In English, from here it looks like your short block is muy bueno, but for the smoothest

operation your cylinder heads could use a valve job.

A little more food for thought concerning the leakdown test results vs rough running.

Think about how a 4-stroke engine goes through a complete cycle. After the power

stroke, we immediately go into the exhaust stroke. Towards the very end of the

exhaust stroke, the piston is actually chasing the exhaust valve up towards the

cylinder head.

Right in the middle of all this, as the piston is slowing to a complete (momentary) stop,

the intake valve starts to open. This means that for a short period of time, both the

exhaust and intake valves are open. (This is the overlap period, very short on a smooth

idling stock cam, quite a bit more on a high rpm performance cam.)

Right in this time period, the exhaust valve closes while the intake valve continues to

open and the piston starts to accelerate away from the cylinder head. IF the exhaust

valve/valve seat is leaky, guess what happens during this period? Think of the extra

exhaust gas dilution occurring in this high vacuum environment as an overactive EGR

event on top of the EGR already being commanded by the ECM upstream in the

intake manifold. (!)

To finish explaining why (slightly) leaky exhaust valves can cause rough running, but

only during light throttle situations, let's let the intake stroke complete, and start

up the compression stroke. Most folks think that the intake and exhaust valves

are only held shut by the valve spring above.

But there is a 2nd force acting upon the valves, and that's the increasing cylinder

pressure pushing on the circular face of the valves themselves, providing dynamic

additional closing force. (Total square inches of valve face area x cylinder pressure

in PSI.) Especially with a successful cylinder firing, the pressures are way up there.

BUT, if too much exhaust gas dilution from the leaky exhaust valve seal coincident with

running 14+ inches of vacuum in the intake manifold (because the throttle blades are

barely cracked during cruise/coasting driving) causes there to be nothing burnable

in the vicinity of the spark plug gap when it fires...then we end up with a misfire.

But guess what? IF we step into the gas, and the ratio of uncontrolled EGR

(from the leaky exhaust valve) is now being overwhelmed by a rich, dense

intake charge, now the cylinder is going to easily fire with authority.

Apologies for that dense passage. And the fact that you may have to read

it a couple of times in order for it to make sense.

The point I'm trying to make is that back in the pre-emission days IF we got

a compression test with a +/- 5% spread and we were getting a rough idle or

light throttle roughness? We'd simply fix the issue by cranking out the idle

screws a 1/4 or 1/2 turn, and all would be right with the world. (In extreme

cases, we might also read the bone white spark plug porcelains & rejet the

primaries to a little less stingy size. :0)

Because we'd cover up this uncontrolled EGR situation without even really

knowing exactly why. (Back then, most compression testing on customer

cars was simply to quantify gross failures in order to sell a valve job, and I

remember reading about how only the hottest circle track dudes fussed around

with exotic procedures like leakdown testing.)

But today? With the O2 sensors holding the truck to a strict 14.7:1 air/fuel

ratio, even at idle, up through part throttle (ie: not full power open loop) ...well

now we can no longer cover this up. And these big bore big blocks will oftentimes

run dead smooth under load, but be a little sloppy at idle and light loads.

(With optimal quench this issue isn't as bad, but with normal tolerances

there are simply a lot of square inches in the combustion chamber where

there's no spark plug to light off the one good spot of combustible mix

thanks to the marginal exhaust valve sealing.)

And all this can occur with perfect spark plugs, wires, cap, rotor, coil, etc.,

*if* you have exhaust valves where you can hear the 100 psi air escaping

out the tailpipe at TDC on the compression stroke.

To recap, your test data suggests to me that you have a great short block,

the intake valve in cylinder #1 is tired, and a total of (7) exhaust valves are

leaky. A valve job would go a long way to laying the foundation for a 454

that runs as smooth as new at all expected speeds and loadings.

More in a bit, for I want to ask for some additional data from you if you

are still interested in pursuing a fix. I appreciate your willingness to dig

deeper than most, and being so patient with the process.

Cheers --