Im back with an update have had the rona and plumbing issues so i am back on the truck.

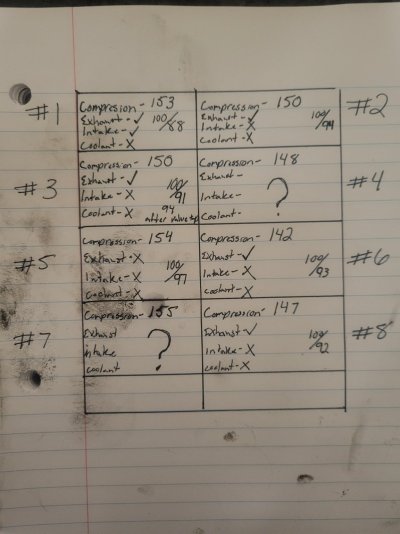

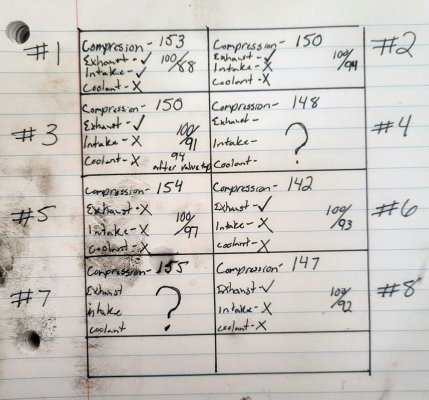

Ive logged all the data i can and ive noticed something weird with number 7 and 4 any time i try too bring the cylinder up tdc the exhaust valves open befor i get there. Ive repeated both of those cylinders numerous times with the same results.

My data below check mark means air heard. X nothing heard.

Elevatorman,

THANK YOU for following through and capturing the requested data for both

the Compression Test *and* the Leakdown Test. Listen, I'm flirting with running

late for an appt. at the VA hospital, but thanks to the results of your leakdown data

I think I've had a troubleshooting Eureka moment. So to get this out asap for the

GMT400 community to review, here's my thoughts, bullet style:

* The *camshaft* is the mechanical computer that sets the firing order for the engine.

* The PO installed a camshaft featuring the "4-7 swap". (This is popular with the outer orbit motorhead devos for reasons we don't care about right now.)

* The factory firing order that we all know, love, and can recite anytime, anywhere:

1-8-4-3-6-5-7-2.

* Hot, hip 4-7 swap firing order: 1-8-7-3-6-5-4-2. (Note: It does remove the "5-7" adjacent firing & moves it to 4-2? Taming 5-7 hot spot is claimed?)

* A compression test will NOT find a firing order change.

* A leakdown test performed sequentially (every 90° of crank rotation) will uncover a non-standard firing order.

* And if the cam has the 4-7 swap, you will end up with *exactly* the test results that you documented, for you

will end up attempting to test cylinders #4 and #7 in the vicinity of the Exhaust/Intake overlap {360° out} instead

of the both valves closed top of the compression stroke. (!)

While I'm taking care of business, check out something I drew to help you follow the troubleshooting theory:

You must be registered for see images attach

NOTE: I've attached a copy of your test results so that you can use them against the chart above.

Q1: How are your spark plug wires run? I'm assuming the factory firing order to match the cap?

Or did you replace them one at a time, and maybe the PO followed the new cam's firing order?

Q2: Is the wiring harness for the 8 sequential fuel injectors still stock, or did the PO attempt

to modify/hack the wiring harness to follow the new camshaft firing order?

Q3: Could you attempt to prove/disprove the firing order that's currently installed in your truck?

****

More later, gotta show up for my Dr's appt.

Best of luck figuring out exactly where and how much total 'value-added' the PO left behind in the

engine bay besides the aforementioned inline resistor to one of your sensors.

Cheers --