SinnSix

Newbie

Hi fam, long time Chevy owner, first time posting.

I have a new to me 1996 5.7 Vortec 2 door 4x4 Tahoe. 300k on the ODO, swapped in motor has 180k. 40k on trans.

Newer fuel pump, new fuel filter.

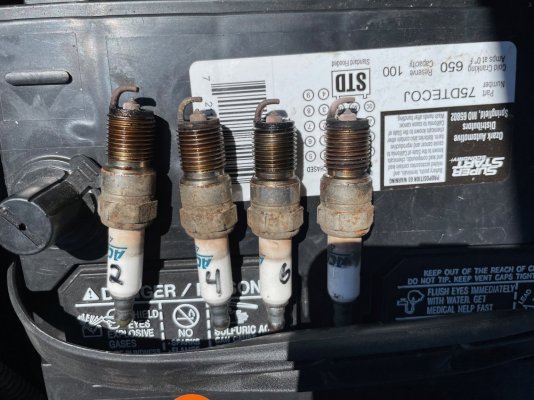

Cap, wires and plugs unknown (they look heavily worn.)

I’m in California and subject to smog. Which once this issue is resolved I will be heading straight to a smog station.

I have read through all the posts I could find about sputtering and misses, but none seem to act the way mine does, with the vortec injection.

Truck starts with one or two extra uggah-duggas and runs wonderfully. Treated it with a few cans of seafoam in the tank and 1/2 in the intake.

Truck runs 80mph on the freeway with no issues if I ease into it.

The issue is If I get more than 1/2 throttle under load at any speed, she bucks and sputters, it gets worse the harder I accelerate. Seems to have a miss but I can’t tell if it’s fuel (injection spider, fuel pump) or spark causing it. I am leaning towards fuel. One of these next weekends I’m going to borrow a fuel pressure gauge from auto parts place to make sure I have 55-60 psi fuel pressure.

I’m on a tight budget so I kind of have to pick something to replace it will have to be the injection spider or the spark kit. The kicker about this whole thing is that it hasn’t thrown a single code. The longer I run it after the seafoam treatment, the better it seems to run, but still sputters under heavy throttle. Has anyone else had an issue like this?

I read somewhere on another forum a post about the Crankshaft position sensor possibly needing shims due to crankwalk under load on high mileage motors. Please let me know if anyone has experience with this.

Any input would be greatly appreciated.

Thanks

Sinn

I have a new to me 1996 5.7 Vortec 2 door 4x4 Tahoe. 300k on the ODO, swapped in motor has 180k. 40k on trans.

Newer fuel pump, new fuel filter.

Cap, wires and plugs unknown (they look heavily worn.)

I’m in California and subject to smog. Which once this issue is resolved I will be heading straight to a smog station.

I have read through all the posts I could find about sputtering and misses, but none seem to act the way mine does, with the vortec injection.

Truck starts with one or two extra uggah-duggas and runs wonderfully. Treated it with a few cans of seafoam in the tank and 1/2 in the intake.

Truck runs 80mph on the freeway with no issues if I ease into it.

The issue is If I get more than 1/2 throttle under load at any speed, she bucks and sputters, it gets worse the harder I accelerate. Seems to have a miss but I can’t tell if it’s fuel (injection spider, fuel pump) or spark causing it. I am leaning towards fuel. One of these next weekends I’m going to borrow a fuel pressure gauge from auto parts place to make sure I have 55-60 psi fuel pressure.

I’m on a tight budget so I kind of have to pick something to replace it will have to be the injection spider or the spark kit. The kicker about this whole thing is that it hasn’t thrown a single code. The longer I run it after the seafoam treatment, the better it seems to run, but still sputters under heavy throttle. Has anyone else had an issue like this?

I read somewhere on another forum a post about the Crankshaft position sensor possibly needing shims due to crankwalk under load on high mileage motors. Please let me know if anyone has experience with this.

Any input would be greatly appreciated.

Thanks

Sinn