My 1999 C1500 Sub runs great (well, for now lol) and is approaching 260 miles. L31 Vortec 5.7. Cylinder heads, new mpfi injectors, and lifters replaced a couple years ago. No knocking, oil kept changed, and I drive it hard, maybe 5k miles per year. Trans fluid swapped annually (pan drop, I have a drain on the pan).

Got a free new timing chain from a friend recently who had the same year truck and sold it.

I'm thinking about swapping the timing chain next time I do a coolant flush.

I like your thought process, for Preventive Maintenance now is preferable to being stuck on the side of the road

later, especially during precious vacation / family outing time.

****

Here's a thought. I'm thinking that your L31 Vortec was built with a roller chain, and they can run a lot of miles

without developing excess stretch. (Assuming regular oil changes.) But before disturbing the status quo, how about we

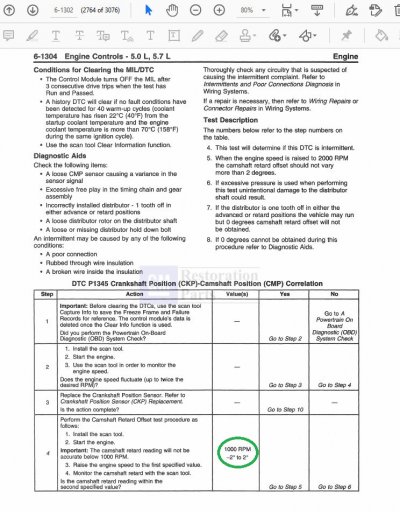

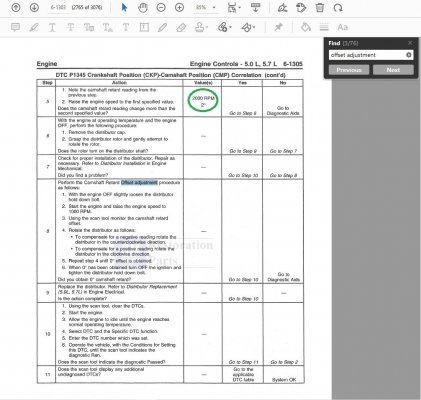

(mis)use the 'CMP Ret' to first measure the amount of play between the front of the crank (CKP sensor) and

the distributor? (CMP sensor)

In English (assuming a healthy distributor & distributor gear) any change in the 'CMP Ret' reading will be the

direct result of play in the timing chain. The GM spec is no more than a 2° change from what you read at 1000 rpm

vs. 2000 rpm. I would expect on a fresh motor with a Cloyes chain that the CMP Ret reading wouldn't vary hardly

any from 1000-3000, and wouldn't be jumpy due to a worn timing chain allowing the cam to break into rotational harmonics

stimulated by the pulsating loads brought on by the torque needed to push those valve spring loaded lifters up their

respective bores by the cam lobe(s).

Well, maybe that previous paragraph wasn't in English? What I'm trying to describe is that instead of a steady resistance

to turning, the cam has some cam lobes resisting turning (due to valve springs being compressed by the opening ramps) ...while

at the same time there are other cam lobes actually trying to turn the cam forwards in the desired direction. (due to the valve

spring/lifter combo on the closing ramps)

All these torque pulses (in both directions) occurring during cam rotation is what causes worn timing chains to really 'flutter'

while spinning. (Note: Easily observed using a timing light to monitor ignition timing jumping around wildly while the engine is

held at a steady highway cruise rpm.)

Note that any back/forth movement of the camshaft is going to lead to 'spark scatter', superimposed upon the pulsations

already coming from the oil pump below. All these dynamic errors are easily seen if you put the CKP signal on Channel A of your scope

(and also trigger off of this) while putting the CMP signal on Channel B of your scope. Pretty boring dual trace display on a new,

close-tolerance engine, a lot more interesting on a tired engine with lots of miles on the clock.

But if you aren't a scope dope, then a scan tool that can show the 'CMP Ret' signal is the next best thing. And way easier to

check than it was to wade through all of the above. :0)

****

One last thing. Others have already mentioned building up a spare L31 engine while you are still driving on this one.

This is definitely the way to go. A prudent owner of a high mileage truck would do this in order to maximize the

up time vs. down time. By having this ready to go ahead of time giving yourself the gift of a new, known-good

powerplant is a no-sweat 1 weekend affair along the lines of what EricTheAweful stated above.

And if you have a sincere appreciation for self-reliance in an uncertain future, once the truck is up and running on

the new motor, you promptly take that broken-in original motor and refresh *that* as well, and you then put it up

on the shelf as a ready to rock 'just in case' backup strategy.

Doing all of this under 'my DD is down' time constraints is a stressful grind & zero fun. But doing the above

before you need it? It's fun, and it also feels smart while doing so. FWIW, this is the direction that I'm headed in

myself.

But to pull this all together, if you have the inclination, why not have the computer tell you just how healthy your timing

chain is in order to help decide whether I should do this now vs down the road a ways?

FWIW --