L31MaxExpress

I'm Awesome

I can't argue that. I would, however, expect to see a "clean" path where the hot coolant flowed from the coolant crossover in the intake manifold into #1 intake port; and I'd expect to see the evidence of hot coolant "steam-cleaning" the intake port. But the photos don't show the floor of the port, only some of the roof.

Another reason to use the leakdown tester--if he pressurizes the cylinder for a minute or five and can find no bubbles in the radiator, the likelyhood of the coolant passing by the intake gasket increases. I'd think a big leak like he has would show up under ~100 psi if it were a gasket, and maybe even if it were a cracked casting. Not guaranteed...but likely.

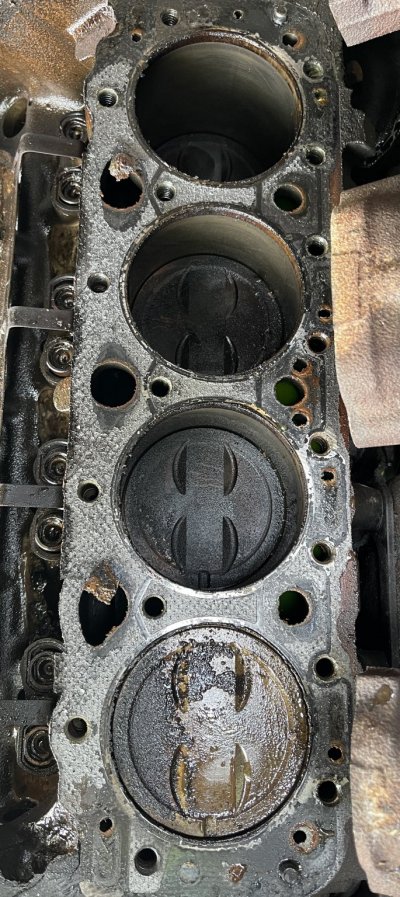

My leak did not show up until the van was parked for 3 weeks. It was a seaping through, but it only takes ~70cc of liquid to hydraulic lock a L30 and like ~80cc to lock a L31. My #2 intake port had coolant standing in it after the catastrophic event.