so knowing this i know that unless your led lights have 3 wires coming out of them then you cannot run them as running lights and turn signals.

If the desired look is that the tool box side lights flash IN SYNC with your OEM turn signals, this statement is true. A typical trailer turn/brake/running light would be your only option in this case with LEDs. Which can run you $20-40 a light, as compared to marker lights that cost $5-10.

However, if you'd be willing to spend a lil bit more cash ($10-15) and time for this, there is a way to have your tool box side lights still signal your direction of turning AND have them as marker lights. (There isn't a way to get your red lights to be running AND brakes besides buying a trailer turn/brake/running light) Keep in mind, as of right now, this plan is a theory I have yet to prove 100% correct. But I can say with 90% certainty that it should.

You wanna get two

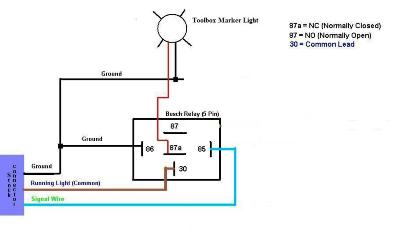

5-prong relays/isolated switches. I'm assuming that you want your tool box lights to turn on when you turn your headlights/parking-lamps on. In which case, the two relays are all the extra materials you need (besides more wire if you think you're running low and Push-On female wire terminals to connect to the prongs on the relays).

Here we go. I'll explain this for the driver side lights and you can repeat these actions for the passenger side (differences will be mentioned). Run your positive wires to your LED's down your frame and up into your engine bay/under the hood. Be sure to have your left and right side wires separate. Pick a nice spot to mount the relays that allows for easy access and installation. Get a hold of your front marker lamp wiring (best to just take off the marker lamp housing and pull the bulbs out). According to a 94-98 wiring diagram, there should be three wires there. One Brown (running lights), one Black (ground, leave alone), and one LIGHT BLUE (left signal light). You're better off splicing into the brown wire with TWO wires, one for the left side running light relay and one for the right. This makes it easier to wire into your relays, because you'll most likely mount the relays somewhere on the driver side of the engine bay. You then want to splice into the LIGHT BLUE wire and run that to your driver/left side relay. This here is a diagram I found and tweaked to match this here application:

109717[/ATTACH]"]

You must be registered for see images attach

You want to ground your relay to any nearby bolt that is already grounding something or makes bare metal contact with the body/frame. Splicing into OEM ground wires is just a waste of time because the point of grounding something is that you only have to run one wire (positive) to your load and then ground it nearby. Follow the diagram for your passenger side marker light wiring process, except the passenger side directional/turn signal wire is BLUE (not light blue. normal blue). That honestly should be all you need to do. Clean everything up and you should be solid. Good luck!

The outcome will be that when your OEM maker light is on, your side toolbox lights will be on. When you activate your signal, your toolbox light will flash OUT OF SYNC with your OEM turn signals. When your OEM signal light flashes ON, your toolbox marker/turn light for that side will be OFF. When your OEM signal light flashes OFF, your toolbox marker/turn light will be ON. Its different and unique. I wired a set up like this on a buddy of mine's headache rack and it looks pretty cool. It wasn't wired up the exact same way because he had incandescent lights so we were able to take a few shortcuts cause polarity doesn't matter for incandescent lights, but for LED's it does.

BTW: The reason a 5-pin relay should be used is because its simpler, and if you ever want to put lights on that are ONLY turn signals, you can plug them into pin 87 and they will flash IN SYNC with your OEM signal lights. They won't work as running lights though.

I know this post is probably super late and may no longer be useful to the original thread poster. I feel that this will help anyone else who is searching on how to wire up marker lights into running AND turn signals.