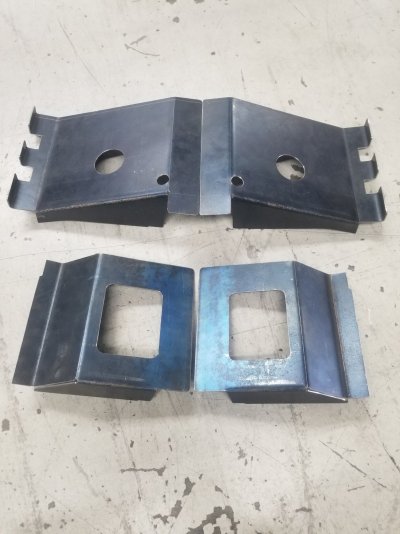

Since some of y'all enjoy watching bodywork, heres some more project pix. I hope you get ideas out of this for your projects. Welded in new trunk hinge supports. Old ones were hacked off at the bottom.

Note the gray painted temporary tube support in pic 1. That was to raise the height of the quarter to get the trunk weatherstrip rail to 17" as it sagged with the old trunk hinge supports cut off at the bottom, and allowed a gap where the trunk forward corners sat up higher at the front. I did this on both sides to set the height. Once the supports were welded in, I took these tubes out on either side and the height remained at 17". I took that measurement off the green 69 barracuda back half I drilled apart for these pieces and more.

From there after getting the correct height established, I moved on to fitting the dutchman panel. This piece is normally $180 from AMD. I lucked out. Somebody had one for sale on the other forum I am on, they never used it. Looked like it made the rounds to a few swap meets. It had a sticker on it that said $80. The dude sold it to me for $50 4 years ago. It's been sitting in the corner of the shop with the sheetmetal for the rest of this thing. The original was severely rotted on all 4 corners.

I made a lot of rust bunnies, however in the end, it's nice working on clean primered metal. The white primered hinge supports off the donor were sandblasted clean, then epoxy primered. It felt like I was installing new pieces.