Moparmat2000

I'm Awesome

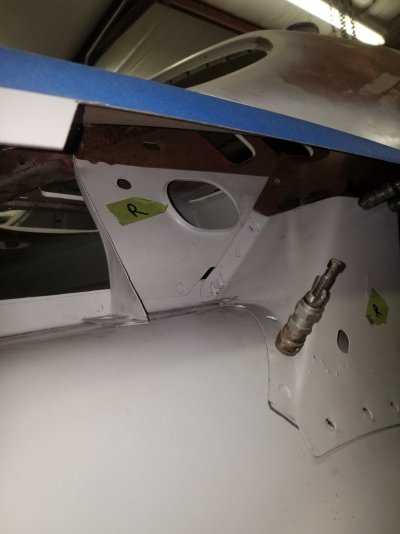

The severe rust through issues extended between the rain gutter and rear quarter upper flange at the trunk opening. There was perforation everywhere, and spots where rust was between both layers of steel trying to pop it apart. The green barracuda rear half I drilled apart gave me the tops of the quarter skins from the door opening back. The trunk jambs were what I was after. Light surface rust is all that was there on the donor. I decided to seam these in 1" forward of the trunk opening. Once everything is fitted on both sides, I will un clamp it, sandblast the pieces, and epoxy primer. Then I will reassemble it permanently.

The clamps with the wingnuts are called buttweld clamps. I got these at harbor freight. Note the gray steel tube temp welded to hold the taillight frame structure in position while everything is apart. I will do the same for the LH side, then tie them together with a welded bar running straight across so I maintain the 52.5" spacing at the trunk opening.

The clamps with the wingnuts are called buttweld clamps. I got these at harbor freight. Note the gray steel tube temp welded to hold the taillight frame structure in position while everything is apart. I will do the same for the LH side, then tie them together with a welded bar running straight across so I maintain the 52.5" spacing at the trunk opening.

Attachments

Last edited: