1992 C1500 5.7 Ext. Cab

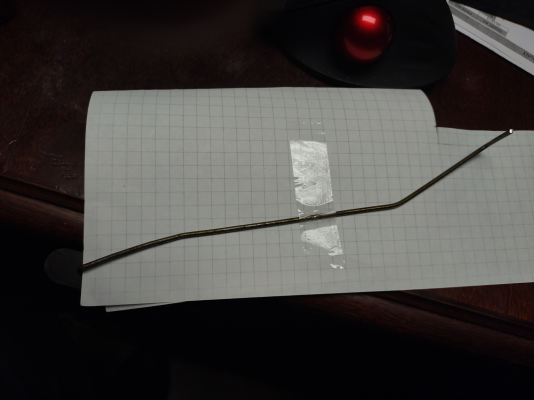

The wires from my sending unit to the first connection (C407?) at the frame rail were crushed between the tank and crossmember. How can I test that short section of wire to see if a signal is being sent to the gauge?

My gas gauge points to 3:00, way past Full. If I ground the purple/pink wire, it goes to Empty as expected. I think the instrument cluster works fine because of this. I cleaned the connection of the black ground wire running from the top of the tank unit to the frame and the wire is in good shape. As a matter of fact, the sending unit was replaced about 12,000(?) miles ago by the dealership. They installed the tank with the wires between the tank and crossmember, crushing them when the straps were tightened. I think after a while, something finally gave out. While the diagnostic procedure indicates I should replace the sending unit, I would like to test the pigtail running from the sending unit. The power wire works as the fuel pump runs fine. I'm not sure if the other two wires are good. They look OK and I don't see any breaks in the insulation.

The sending unit is relatively new - did I just get a bad one? I hate to drop the tank or tilt/remove the bed and pull it if I don't have to. I'd like to test the wires first.

The wires from my sending unit to the first connection (C407?) at the frame rail were crushed between the tank and crossmember. How can I test that short section of wire to see if a signal is being sent to the gauge?

My gas gauge points to 3:00, way past Full. If I ground the purple/pink wire, it goes to Empty as expected. I think the instrument cluster works fine because of this. I cleaned the connection of the black ground wire running from the top of the tank unit to the frame and the wire is in good shape. As a matter of fact, the sending unit was replaced about 12,000(?) miles ago by the dealership. They installed the tank with the wires between the tank and crossmember, crushing them when the straps were tightened. I think after a while, something finally gave out. While the diagnostic procedure indicates I should replace the sending unit, I would like to test the pigtail running from the sending unit. The power wire works as the fuel pump runs fine. I'm not sure if the other two wires are good. They look OK and I don't see any breaks in the insulation.

The sending unit is relatively new - did I just get a bad one? I hate to drop the tank or tilt/remove the bed and pull it if I don't have to. I'd like to test the wires first.