Your daisy chain theory has no basis in fact. Nor is that how pcm controls the power train . That is a guess. If want to do your own service , invest in the correct service manuals, and the tools you need. It has a computer, invest in scanner not code reader.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dies without throttle until warm

- Thread starter Rustjunky67

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Rustjunky67

I'm Awesome

Thanks I have requested to get on the list. We'll see how it goes if I get it lol.Looks like the community Snap-On scan tool has reached the end of the list of people who needed to use it, you could sign up in that thread and get on the list.

https://www.gmt400.com/threads/gmt400-community-scan-tool.60565/page-19

Rustjunky67

I'm Awesome

Alright guys I have a lot going on right now so didn't get to touch truck until right before dark tonight and just wanted to see what it would do one more time.

I don't recall if I mentioned it but when the idle is coming down, as soon as it hits the 1k rpm mark (factory dash tach), it instantly dies as if the key was cut off.....

Same thing again this evening....

That HAS TO BE an indication of something specific that one of you geniuses can correlate to a part or step to take that will fix this otherwise "better than since I've had it" running truck. That 1k rpm instantaneous cutoff has got to ring a bell with somebody. Anyone?

I don't recall if I mentioned it but when the idle is coming down, as soon as it hits the 1k rpm mark (factory dash tach), it instantly dies as if the key was cut off.....

Same thing again this evening....

That HAS TO BE an indication of something specific that one of you geniuses can correlate to a part or step to take that will fix this otherwise "better than since I've had it" running truck. That 1k rpm instantaneous cutoff has got to ring a bell with somebody. Anyone?

Rustjunky67

I'm Awesome

Here's a video of exactly what's happening....

starts by barely hitting key (ONLY WHEN COLD START).....

Runs as smooth as you could ask with idle at 1500 rpm...

AS SOON AS it hits 1k rpm it's like I switched key off.....

I can get it to restart with fluid but I have to keep throttle to it and it runs rough after that initial start....

UNLESS I run it long enough for motor to warm up good then from that point on it runs as good as you could ask and better than it ever has since I've owned it.....

WHAT IN THE WORLD is causing this? It is about to drive me INSANE!!!

starts by barely hitting key (ONLY WHEN COLD START).....

Runs as smooth as you could ask with idle at 1500 rpm...

AS SOON AS it hits 1k rpm it's like I switched key off.....

I can get it to restart with fluid but I have to keep throttle to it and it runs rough after that initial start....

UNLESS I run it long enough for motor to warm up good then from that point on it runs as good as you could ask and better than it ever has since I've owned it.....

WHAT IN THE WORLD is causing this? It is about to drive me INSANE!!!

xc_hide_links_from_guests_guests_error_hide_media

Here's a video of exactly what's happening....

starts by barely hitting key (ONLY WHEN COLD START).....

Runs as smooth as you could ask with idle at 1500 rpm...

AS SOON AS it hits 1k rpm it's like I switched key off.....

I can get it to restart with fluid but I have to keep throttle to it and it runs rough after that initial start....

UNLESS I run it long enough for motor to warm up good then from that point on it runs as good as you could ask and better than it ever has since I've owned it.....

WHAT IN THE WORLD is causing this? It is about to drive me INSANE!!!

xc_hide_links_from_guests_guests_error_hide_media

Rustjunky67,

Your problem has a specific/unique footprint, and is intriguing. Instead of trying to weave the following together

into some grand unified theory, instead I'm just going to list a few observations, with the hope that the

subject matter experts can chime in.

* FWIW, in a previous life I used to teach troubleshooting, both analog, digital, and closed loop electromechanical.

A point I used to stress over & over was that you couldn't fix an intermittent until you could first figure out how

to break it at will. Congratulations! - as you demo'd in your video, you have just figured out the hardest part of the problem.

* I think that an important point to keep in mind is that once the engine is fully warmed up, you are happy with the

way it runs. (!) This is good for a couple of reasons. First of all, this makes the problem a bounded one, in that

the system starts fine. Then it fails. But once it's fully warmed up, it again runs fine.

This is much easier to troubleshoot than an engine that works fine cold, but always runs rough when warmed up.

Could be anything: mechanical (compression), or a thermal fault in the ignition (spark), or a weak fuel pump. (fuel)

So let's keep this important clue in mind. How can an engine start fine, stall suddenly right at 1,000 rpm -- but if you

continue to nurse it/warm it up to normal operating temps it will run fine for the rest of the day?

* You don't have the GMT400 community scan tool yet. But this is in the works? Well, instead of just relying solely

on the scan tool to show you the way, I propose that we troubleshoot this old school first, come up with a theory based

upon our observations, and then when the scan tool shows up, we can use it to confirm/deny our theory?

For example, if I was your neighbor, since you have figured out how to break this at will, I would want to try to 'see'

what's going on as much as possible. We could get not one but 2 important clues by going to the cold engine, and

connecting a good vacuum gauge and a timing light to it first. Then start the engine, and let that timing light flash

away while watching that vacuum gauge closely.

By definition, in general terms the more vacuum that the engine can pull against the closed throttle plate the healthier it is.

(stock cam & tune.) If you have 2 identical engines running side by side, and the first one is giving you 20 inches

of steady vacuum at 1200 rpm, while the second engine is giving me a shaky 12 inches of vacuum at the same

1200 rpm, then I already know that one engine is right with the world, and the other one ain't.

So, with nothing more than a vacuum gauge, I want to see what your engine gives me right after startup? Is it

dropping off slowly as the rpm drops, until it's much lower than it should be and the engine finally shudders to a halt?

Or does the vacuum stay nice & high, all the way down to 1000 rpm, and then it is lost suddenly, as if you turned the

key to the off position? (Think sick engine as perpetrator of stopping? Or is it a healthy engine that is the victim of a

supporting function suddenly disappearing?)

And this is where the timing light comes in. I'd be watching for a steady flash flash flash right from start up. And as the

engine gets closer to the magic 1000 rpm, I want to see if A) the flashes continue, but slow down in time with the

engine rpm? Or B), do the timing light flashes suddenly quit, and then the engine comes to a stop?

So, with just a vacuum gauge & a timing light, I think we can collect some old school solid troubleshooting data while

waiting for the scan tool to show up and put it's laser focus on the broken area, whether a marginal part during open

loop operation is being compensated for once the engine warms up & the system transitions into closed loop mode.

Or whatever. But, the less guessing = the more champagne we are going to spray around when we get to perform a

premeditated fix based upon our careful observations. :0)

Could we do even better? A: Yes. I'm not a TBI guru, but supposedly there's some sort of in-line adapter tee thingy

that gives you a test port to monitor fuel pressure while the engine is running? If this is true, then imagine

monitoring the fuel pressure + timing light + vacuum gauge as the engine goes from fine at 1200 to 1000 to stall?

Spark + Fuel + Compression = it has to run. Even at 1000 rpm during the warm up. (!)

* Important history of operation question: Since you have owned this truck, was there ever a time that it was able

to go from a cold start to fully warmed up without this failure occurring? If so, can you tell me when it went from

good to bad? (Before some new tune up parts were installed last spring, a valve job a year ago...or maybe it was last

August 3rd at 4pm, right before a fender bender in the Piggly Wiggly parking lot? And it was never the same since?

I'm being serious. You mentioned that the truck is running better than it has in 'the last 10 years'? The key to tightening

up the problem description is to figure out as close as you can to when it was the last time the machine was good versus

the very specific symptom that it has now? Once we have the moment in time where the problem started nailed down, now

we can try to figure out what related changes occurred during this state transition/window in time that we need to focus on

first.

You see, there are numerous Possibilities for the root cause of this misbehavior, but instead of random shotgunning, we want

to organize all of these Possibilites into a list, from Highest to Lowest Probability. Once we establish that, *then* we should

be able to come up with some structured testing that will allow us to further tighten up the problem definition before ordering

a part. Or 2. But not 2 dozen parts. :0)

For example, if everything was fine until the fuel pump had to be replaced, and subsequently we have this strange symptom, I'm going to

put everything related to that maintenance as a higher probability than, say, investigating the charging system or performing a

compression check. (Not removing any Possibilities from the table, but just trying to assign relative Probability to each individual link in the

internal combustion success chain.)

Now, it's quite possible that the problem came on slowly over time, instead of a step function. Not only is that a valid observation, but

it also can help us eliminate the stuff that is known to work perfectly right up to the moment that it fails completely. (Like a light bulb.)

And I've also worked on stuff that the new owner had never personally seen work properly. Ever. Bought the thing as a 'basket case' on purpose.

Or bought a real cream puff in good faith, but the pretty (yet unreliable) vehicle with a beautiful facade had stayed in the PO's garage all

those years for a reason...but this detail wasn't disclosed by the seller?

Normally these old lemons resist repair due to nested, overlapping issues. Think of a chain where, instead of a single bad link, there's 3

or 4 weak ones that you have to weed out, one failure after the other, before you finally end up with a reliable chain with hundreds of good

links left to do your bidding. Pretty rare, and unfair, but it can & does happen.

Subject Matter Expert time:

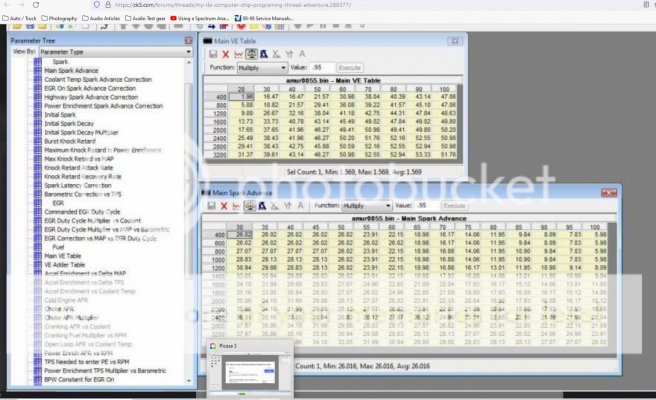

* Let's say that all the normal stuff (grounds, wiring harness, normal tune up bits, TBI operation) is verified good with the scan tool.

Is it possible for there to be 1 or more corrupted memory locations in the ECU's PROM that have goofed the values in a small number of

specific cells that are only mapped to with the right combination of engine coolant temps, MAP, and rpm? Is this memory parity checked or

ECC protected, so that if there was a failure it would be detectable as a parity failure during power-up self-test and throw a Pxxxx code with

a MIL/SES light? Or there's ECC that allows the system to fix single bit failures on the fly? (See attachment for visual representation of

discrete cells in the lookup tables.)

* Or, would a higher probability be that the ECU in the OP's truck was a Reman unit, and the PROM is correctly holding onto

one or more cells filled with bad data (from an latent corrupted image) written into it during the remanufacturing process?

To me, this would both explain a lack of a power-up self-test failure/Pxxxx code, yet at the same time giving the engine something to starve/choke

on during warm up?

I ask this because the FSM was big on the dealer tech checking for/updating the ECUs with the latest version of the software? Is there an old

technical bulletin that describes a driveability issue like this fixed with version Foo of the code?

EDIT:

* Is this a case where the aging capacitors are weakened, and now we've got all kinds of RFI and/or ripply AC on top of the DC

that we're trying to run this computer with? Got junk leaking into one or more of the +5.0 volt reference voltages that feeds into

the sensor, and therefore could cause the resulting noise-modulated output to mislead the ECU after the A/D conversion step?

NOTE: I used to think of these computers as always the infallible victim of bad data from the sensors, but decades after they were initially built

maybe we have to consider the possibility that the ECU can be the perpetrator, not the victim? (Last resort of course.) But I'm just trying

to reason through why it seems like the computer is stepping into a corrupted cell, and that is what we are smelling?

* What ratio is the 'authority' of each of the input variables during Open Loop operation? ECT vs MAP, vs TPS? In most systems

like this some inputs make for small changes in the output, whereas other inputs can make a small change & cause a major

change in the output? Hint: Given that the TBI is a wet intake manifold with no exhaust crossover heating, I'd assume that

calibrating fueling vs engine temp during warm up is touchy/critical to both meeting ever-tightening emissions during the

cat warm-up phase, while at the same time delivering reasonable driveability for the owner? A bit of a calibration tightrope,

where if the engine bay is just a little off it will show up here first?

* Last but not least, the OP mentioned having to sometimes spray a little starting fluid to get it running again once it suddenly stalled

out?

****

Rustjunky67, as you can see, if you can provide an answer to when the truck went from good to bad with this particular issue,

the more we can tighten up the problem statement, moving from exotic wide-ranging theories towards concrete, minimal-cost

focused fixing. No doubt that what I wrote above will generate more questions than answers, but that's not a bad thing when

troubleshooting a stubborn issue like this.

But I wrote all this because if the engine starts fine, always stops at 1000 rpm, and then warms up & runs right the rest of the

day, then we aren't looking at gross mechanical issues, are we? I'm thinking that by watching a vacuum gauge, a timing light,

and (hopefully) watching a fuel pressure gauge while the engine stalls we can come up with some ideas to prove/disprove with

the scan tool.

SBC, TBI, & ECU gurus, please chime in with what you think.

Thanks for your time & attention to this troubleshooting opportunity...

Attachments

Last edited:

DerekTheGreat

Forum Regular

...I don't recall if I mentioned it but when the idle is coming down, as soon as it hits the 1k rpm mark (factory dash tach), it instantly dies as if the key was cut off.....

Same thing again this evening....

...That 1k rpm instantaneous cutoff has got to ring a bell with somebody. Anyone?

My '89 started to do this after I replaced the cap, wires, plugs & rotor one time. Turned out it was the ICM. I pulled the EST wire (under the black cover on the passenger side firewall) and it would idle below 1,000 rpm all day long. When plugged back in, it would die. I replaced the ICM and all was well.

Insert Quarter

I'm Awesome

Couldn't see in the vid if the intake manifold has the EGR on it. When I first bought my truck ('89 5.7L) it wouldn't idle at all until after it warmed up. Ended up needing a new EGR valve. Could just make or buy a block off plate and see if anything changes, ECU would add a code for the EGR though/might turn on the Check Engine Light.

Page 4 in the PDF

RESULTS OF INCORRECT OPERATION

With too much EGR flow at idle, cruise, or cold operation, any of the following conditions may occur: • Engine stops after cold start. • Engine stops at idle after deceleration. • Vehicle surges during cruise. • Rough idle.

If the EGR valve should stay open all of the time, the engine may not idle. • DTC 32 may set (refer to SECTION 3A). Too little or no EGR flow allows combustion temperatures to get too high during acceleration and load conditions. This could cause: • Spark knock (detonation). • Engine overheating.

SYSTEM CHECK Diagnosis of the EGR system is covered in the following charts. These charts begin on Page 9A-4.

Page 4 in the PDF

RESULTS OF INCORRECT OPERATION

With too much EGR flow at idle, cruise, or cold operation, any of the following conditions may occur: • Engine stops after cold start. • Engine stops at idle after deceleration. • Vehicle surges during cruise. • Rough idle.

If the EGR valve should stay open all of the time, the engine may not idle. • DTC 32 may set (refer to SECTION 3A). Too little or no EGR flow allows combustion temperatures to get too high during acceleration and load conditions. This could cause: • Spark knock (detonation). • Engine overheating.

SYSTEM CHECK Diagnosis of the EGR system is covered in the following charts. These charts begin on Page 9A-4.

Attachments

Rustjunky67

I'm Awesome

@Road Trip

Man thank you for this OLD-SCHOOL-NO-SCAN-TOOL, methodical, logical, rational, and most of all freely offered elementary troubleshooting plan.

THIS SHOULD BE SOMEHOW AUTOMATICALLY PINNED AS A NUMBER ONE COMMENT FOR EVERY POST REGARDING POSSIBLE SENSOR, MECHANICAL, AIR, FUEL, AND IGNITION issues. In other words EVERY post..... seriously....

Many of the questions you have are in my posts chronicling my journey over the last 8 months, with me never having even taken a valve cover off before, though always doing routine maintenance my whole life (never taken any of my 35+ vehicles to a mechanic)..... long story short, I had no intentions of going into my motor, was simply going to fix leaking power steering hoses and redo grounds....

Truck had never missed a beat before, always started first try, although had developed some lower rpm hesitation from stop which smoothed out between 1500 and 2k rpm if I recall correctly. So I was going to start with grounds to be sure that base was covered before I did anything, hoping I would get lucky and that would be my solution...... if you don't feel like a good comedy read by perusing my uninformed nonsense, I'll be happy to give you a synopsis but it will be late tonight or tomorrow sometime..... just suffice it to say I procrastinated with every excuse I could find for over a week before I turned that key the first time after putting all back together and to hear it fire up before the key even turned good was like going to Muslim heaven with my harem; I couldn't believe it actually happened..... but then.... but then lol.....I digress for now.....

The info and patience with which you presented it is just what I've been trying to find for MONTHS on forums, YouTube, and anywhere else I could read....K.I.S.S. always provides the most efficient and favorable solution to most problems in my experience in life so thank you from the depths of my toolbox for this; I knew there were people like you out there..... I'll address some more later, I just wanted to tell you right quick how much I appreciate you.

Man thank you for this OLD-SCHOOL-NO-SCAN-TOOL, methodical, logical, rational, and most of all freely offered elementary troubleshooting plan.

THIS SHOULD BE SOMEHOW AUTOMATICALLY PINNED AS A NUMBER ONE COMMENT FOR EVERY POST REGARDING POSSIBLE SENSOR, MECHANICAL, AIR, FUEL, AND IGNITION issues. In other words EVERY post..... seriously....

Many of the questions you have are in my posts chronicling my journey over the last 8 months, with me never having even taken a valve cover off before, though always doing routine maintenance my whole life (never taken any of my 35+ vehicles to a mechanic)..... long story short, I had no intentions of going into my motor, was simply going to fix leaking power steering hoses and redo grounds....

Truck had never missed a beat before, always started first try, although had developed some lower rpm hesitation from stop which smoothed out between 1500 and 2k rpm if I recall correctly. So I was going to start with grounds to be sure that base was covered before I did anything, hoping I would get lucky and that would be my solution...... if you don't feel like a good comedy read by perusing my uninformed nonsense, I'll be happy to give you a synopsis but it will be late tonight or tomorrow sometime..... just suffice it to say I procrastinated with every excuse I could find for over a week before I turned that key the first time after putting all back together and to hear it fire up before the key even turned good was like going to Muslim heaven with my harem; I couldn't believe it actually happened..... but then.... but then lol.....I digress for now.....

The info and patience with which you presented it is just what I've been trying to find for MONTHS on forums, YouTube, and anywhere else I could read....K.I.S.S. always provides the most efficient and favorable solution to most problems in my experience in life so thank you from the depths of my toolbox for this; I knew there were people like you out there..... I'll address some more later, I just wanted to tell you right quick how much I appreciate you.

My pleasure, @Rustjunky67 . I'm here as a student of all things GMT400 -- I have more to

learn than there is time left to make it happen. :0)

And whenever I cross paths with someone else who wants to learn about

whatever they are working on (instead of just paying someone else to do it)

...then I am predisposed to help if I can.

BTW, your description of what it felt like for your engine to fire right up reminded

me of how I feel every time something I've put together lights off for the first time.

As a matter of fact, in a different thread I posted a video of an engine builder who

was able to convey exactly how the first firing feels even better than I can: ( HERE )

Guess what? I'm thinking that once you not only fix this warming-up 1000 rpm stall, but you also

learn exactly why it happened, it will be one of those learning experiences that makes going

through all the frustration & misc cr@p to get there...worth it.

Here's a quote (from an unknown source) I wrote down & keep it on my desk:

"Everything can be viewed as either a beautiful opportunity or a burden --

Either way, you are right."

Let us know what you observe.

Cheers --

learn than there is time left to make it happen. :0)

And whenever I cross paths with someone else who wants to learn about

whatever they are working on (instead of just paying someone else to do it)

...then I am predisposed to help if I can.

BTW, your description of what it felt like for your engine to fire right up reminded

me of how I feel every time something I've put together lights off for the first time.

As a matter of fact, in a different thread I posted a video of an engine builder who

was able to convey exactly how the first firing feels even better than I can: ( HERE )

Guess what? I'm thinking that once you not only fix this warming-up 1000 rpm stall, but you also

learn exactly why it happened, it will be one of those learning experiences that makes going

through all the frustration & misc cr@p to get there...worth it.

Here's a quote (from an unknown source) I wrote down & keep it on my desk:

"Everything can be viewed as either a beautiful opportunity or a burden --

Either way, you are right."

Let us know what you observe.

Cheers --

Last edited:

Similar threads

- Replies

- 3

- Views

- 466

- Replies

- 2

- Views

- 1K

- Replies

- 12

- Views

- 1K

- Replies

- 6

- Views

- 837

- Replies

- 30

- Views

- 4K

Staff online

-

kennythewelderOfficially Retired, B31-3 (6-G) certified welder.

Members online

- gurtomoreno

- 89Cheyenne

- Wheeler454

- Grimm6675

- Amsterdamned96

- OBSChevy88

- NorthState

- PolarBear

- Burnsj79

- Bruce93

- Claymore877

- S_det

- smdk2500

- termite

- OlSarge

- 5vortec7

- BrandonsK2500

- kghawg

- Road Trip

- BradHanks15

- Snowflake870

- Kimm2381

- 99xcss4

- Dcsmith1922

- Caman96

- Cunhaleighton1991

- Carlaisle

- Orpedcrow

- AK49BWL

- shablagoo_gabagool

- scott2093

- EastAZfab

- kennythewelder

- cammiller277

- Hawkbigolecc

- yyoddball

- paveldzh

- heyitzjoel

- Pepsikid628

- BigReb95

- hunterkeslar89

- TechNova

- Davidb

- Komet

- Scupper

- johnckhall

- Alteca

- GrimsterGMC

- Ryanstokes8

- gmt400LEGENDS

Total: 1,563 (members: 58, guests: 1,505)