(TLDR alert)

Greetings Diver88,

That's a good, detailed problem description. In the past I've had a couple of vehicles exhibit very

similar behavior, and in one case I wasn't sure if I'd ever solve the mystery. It seemed that the

vehicle in question had become almost impossibly fussy about the roundness of the tires and the

rotors had to be

absolutely free of measurable warp? I found myself achieving smooth driving, but

after a few weeks the issue would reappear, and then I'd rotate the tires & get them rebalanced,

get the rotors turned, try a different vendor's set of brakes, etc. And then it would be smooth

again, and I'd think, d@mn, I

finally found the right combo...and then a few weeks later the vibrations

would start to become noticeable again. Fudge! :0)

It wasn't until A) I drove a mechanical twin that had zero vibration issues (and had been that way for

some time with no corrective maintenance?) and realized that the design actually

could drive smoothly,

long term, and B) I changed my troubleshooting perspective 180° that I finally solved the recurring

vibration issues.

So I offer the following from the perspective of living through a similar scenario first hand, and it's one

of those food for thought replies, where more questions may be generated than answered...

**** What is your troubleshooting perspective? ****

When troubleshooting a brake pulsation or tire/wheel vibration, the focus is always making sure that

the rotors aren't warped and the tires are round instead of D-shaped from a long (skidding) panic stop.

While performing the diagnosis & repair this way, the perspective is that the Vehicle is the Victim,

and the Parts are the Perpetrators. And 99% of the time this is correct, to the point where this

becomes the *only* troubleshooting perspective by mainstream mechanics who are constantly

improving their career success by biasing their approach on what's the highest probability solutions.

It is simply the way. A high volume of 99% success pays more money than chasing the elusive

solution for the 1-percenter Bad Actors. And by it's behavior, your '96 C1500 has become a Bad Actor.

So to make sure that we aren't overlooking anything, I propose that for troubleshooting purposes

we change our perspective to "The Vehicle is the Perpetrator, and the Parts are the Victims." And

then go on to prove/disprove this until such time as we either uncover the Root Problem, or we are

forced to give up on this approach & go back to the search for the magic combo: a set of NOS GM

rotors, Michelin tires on absolutely straight factory wheels, never again push the brakes on the track until

they stink, + never drive over a deep pothole again on the open road, etc. :0)

So we are going to look for excess play in the front end. And that play could be hiding in plain sight,

but was never looked at because we were looking for a pulsating brake issue from a ever so slightly

warped rotor, while not looking at the front wheel bearings where the preload is out of adjustment

and are allowing the wheel to wobble while rotating, instead of rotating like a lathe?

In order to avoid throwing a ton of parts at the front end, only to end up with an empty wallet and

the brakes are still vibrating, we should attempt to tighten the problem definition as much as possible.

For example, the fact that you have already eliminated the rear brakes from the list of possible failures (by following

Schurkey's recommendation to try stopping the vehicle via the parking brakes only & noting zero vibration)

is excellent. This eliminated a *lot* of real estate from the troubleshooting neighborhood.

In order to support the next level of troubleshooting, we have to figure out what the ratio is between

the total weight of the parts that will inevitably develop minor deviations from perfection during

normal use

versus the weight of the rest of the vehicle. (Which we will consider in our thought experiment as a pure

vibration damper.)

Here's a quick example. Pretty much anyone reading this knows that a 1/2 ounce imbalance on 1 tire

will be noticeable to the owner of the car as a minor change from when it was brand new...but at the same time

a passenger may not notice it. But a 2 ounce imbalance on 1 tire will be noticeable by everyone in the car.

Especially if that car is a 1620-lb '90 Geo Metro. But barely noticeable if that same 2 oz imbalance is on a '63 Lincoln

Continental convertible...or a '99 C2500 HD loaded right to the legal limit.

Here's a better example. Out of your entire fleet, one particular stickshift-equipped truck under your care is suffering

from a shuddering clutch when the driver is starting out from a dead stop. Gotta be a worn clutch disc. Or maybe hot

spots on the flywheel face?

So the clutch is replaced, and the flywheel is resurfaced by a trusted shop that has a good track record for quality work.

And right after the repair, the truck drives fine. But after accumulating a couple thousand miles and a few weeks have

passed, the irritating shuddering is just starting to return, and is getting worse by the week. Assuming the new parts

didn't meet factory specs (which isn't out of the question these days) the clutch is replaced a 2nd time, this time with

the best parts available. These last a little longer than the 1st set...but eventually the shuddering returns? WTF, over?

And finally, the shuddery truck ends up getting sent to an old salty dog mechanic who listens carefully to the history

of the problem, drives the vehicle, returns, opens the hood, chocks the wheels, sets the parking brake, puts the

transmission in reverse, and attempts to back up the truck. When he does this, to the surprise of the onlookers the

driver's side of the engine leaps up almost 2" and drops back down when he pushes the clutch back in.

The solution? The clutch was the victim of a broken motor mount, so instead of only being able to move back & forth

a fraction of an inch before being held in place, the minor torque variations as the clutch was slipping in order to get

the truck moving enjoyed an excessive degree of freedom, so that the combined weight of the entire engine/tranmission

assembly was allowed to break into oscillation. And the ratio of the weight of this vibrating powerplant versus the

weight of the rest of the vehicle made it very easy for the occupants to realize that there was a problem down under

the floorboards. :0)

And on the 3rd repair attempt, the clutch was left alone, and instead the motor & transmission mounts were replaced.

And now the truck drove just like all the others in the fleet. (!)

****

Apologies for the long-winded analogy, but I wanted to illustrate the thought process where we are trying to visualize

A) the forces at play when the brakes are pulsating/vibrating, and B) what's the ratio of the weight of the vibrating

parts vs the weight of the remainder of the subsystem/vehicle?

1) Let's say for the sake of argument that there is excessive wear somewhere in the front suspension of your truck.

But where? First, we need to think about how the weight of the stationary vehicle is transferred from the frame to

the lower control arm. Of course with just the arm the spring is on the top, and the bottom is sitting on the pavement.

That's nonsensical. So in order to allow the vehicle to roll, we add a spindle, (plus an upper control arm to keep

everything straight) wheel bearings on a hub assembly, mount this to the spindle, and finally mount a rubber

tire/steel wheel assy onto the hub. If now you think about how the weight of the truck is transferred from the

frame to the contact patch of the tire, eventually you can visualize how all these parts interact with each other

while sitting there statically.

At this point we have a vehicle that can roll, but only in 1 direction. So to all this we add the ability for the spindle

to pivot left and right under the continuous control of the steering linkage. (Upper & lower ball joints)

Voila! Now a human can sit behind the wheel and exert positive control over this assembly we've just built in our mind.

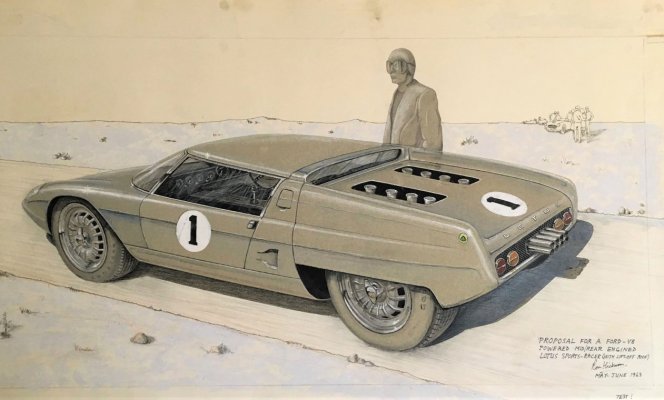

Hopefully what you built up in your mind's eye ended up looking something like this:

You must be registered for see images attach

Now if we roll this truck down a smooth rode, the forces between frame and tire contact patch remain essentially

the same. No problems noted by the driver. Now, the classic scenario from high school Driver's Ed class happens,

where a ball suddenly comes rolling out to the street from between a couple of parked cars. What does the driver do?

He jams on the brakes. (That is, if we remembered to add them to the hub assembly earlier on. :0)

OK, right now I finally have us mentally focused where we need to be. When the calipers clamp the pads firmly

onto the rotors in this emergency stopping scenario, what *new* forces are added to this front suspension assembly?

I'm assuming that the clamped caliper wants to rotate with the spinning rotor, but this isn't allowed to happen thanks to

the spindle bracketry that the caliper is securely bolted to. So these new forces developed by the clamped rotor are

actually transferred to the spindle suspended between the upper & lower control arms?

And if the control arms were underdesigned, then no doubt that they would twist/deform under the braking

stresses. But they don't, thanks to the General's engineers that are paid to think about this stuff during

the design phase. BUT, even though the arms don't deform, they

do transfer these forces to where? Is

it through the upper and lower ball joints, and eventually through the upper & lower control arm bushings

interconnecting the front suspension to the frame? The twisting forces created when we step on the brake

pedal and force those calipers to clamp the brake pads to the spinning rotor have to have an equal and

opposite reaction somewhere, somehow.

And if ALL the mechanical bits involved are unworn and working as the design engineers intended, then these

forces will be transferred silently to the truck's frame, whether the forces are 100% smooth (like Direct Current)

or if there is a small 1% pulsation included from real-world tolerance stackup in the braking subsystem. (Sparky

types would think of this as a 99% DC voltage with a 1% AC ripple superimposed on top of it. :0)

Of course, if the brake rotor is warped like an old 45 rpm record left out in the direct sun, then inevitably the

whole setup can't help but pulsate during a stop. But if you think about it,

slightly worn suspension component(s)

can make a specific vehicle more 'finicky' about the brake components...but only when we ask the associated front

suspension to do -2- things at once.

And especially when you run into the scenario where perfect brake parts drive fine for awhile, but after the inevitable

minor variations develop, instead of absorbing the minor pulsations the worn suspension actually amplifies them.

****

An important credo of the troubleshooter is to first figure out how to break something at will, and also figure

out all the ways that the same system can be used without breaking, figure out what the differences between

these scenarios are, and then focus tightly on that area. Congratulations, you have already figured out the

hard stuff...when it works, and then how to break it at will. (!) The rear brakes have been eliminated, no

complaints about the steering while braking, the brake parts aren't showing any abnormal wear, etc.

Pulling this all together, everything seems to be alright when just the weight of the truck is being transferred

from the frame to the tire's contact patch with the ground. But once we add the twisting forces created

by the clamped caliper wanting to rotate with the spinning rotor, you experience vibration...unless the

brake parts are in perfect condition.

Q: Is it a bad design that will never work smoothly in the real world? A: I don't think so, for a lot of folks

with nearly identical trucks enjoy tens of thousands of brake applications with velvety smooth stopping inbetween

the replacement of wear items. My '99 C2500 has 220K miles on it, and the braking is velvety smooth, and

that's with front rotors and calipers of unknown vintage. They have the normal signs of real-world usage,

but the rest of the truck just doesn't seem to require perfection in order to deliver smooth & consistent braking.

****

Apologies for the length. But if the truck resisted repair from 90K to 227K miles despite several attempts,

then it's going to take more than a bumper sticker's worth of communication to sort this out. The good

news is that you are driving a '96 C1500 instead of an old Lotus Europa, so the chances that you are

eventually going to end up with a set of smooth, confidence-inspiring brakes are much better than average.

Thanks for wading through all this. No doubt the above generated more questions than answers, but

with the combined real-world experience x the analytic horsepower in this forum I'm confident that this

Bad Actor will get sorted out.

Best of luck! Cheers --