DeCaff2007

I'm Awesome

OK the results of the valve adjustment while idling AND the truth about the oil pressure, are both in.

Engine running at idle, at operating temperature.

Dash gauge. Note the oil pressure is at dead 0.

My oil pressure gauge, threaded into the side of the block. Note the 11 (almost 12) psi at idle.

So, even though it's minimal, it's still acceptable. I'm not worrying about the oil pressure any further at this point.

NOW, for the idle valve adjustment. Some valves definitely were adjusted too tight; taking more than one full turn to start clicking/clacking, and then less than a half turn to quiet down... and then the 1/4 turn preload.

Also, according to the aforementioned video, sometimes the engine will bog down to compensate for the sudden vacuum present in the cylinder. Yup, that happened, too. I wasn't necessarily keeping track of which cylinders or valves presented that result. I was more listening closely trying to hear when the clicking started and stopped.

Either way, there's NO QUESTION now as to the correct adjustment of the valve train.

One other thing I must mention here. Earlier, when I say the engine "starts right up", it took a good few cranks to fire. After this running valve adjustment, the engine DOES start easier. So, that's a plus.

Did it help the engine run correctly at part throttle and/or WOT? Absolutely not. Oh, and I opened the hood and gave it a good rev at idle, attempting to see where the backfiring is coming from. Definitely from the Throttle Body.

So, here's my theories as to why it's doing this.

1. Simply near zero gas in the tank. Runs decent on a level surface until given gas. STALLS when even beginning an incline. Barely starts back up and STRUGGLES to maintain the incline.

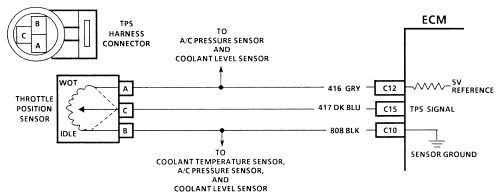

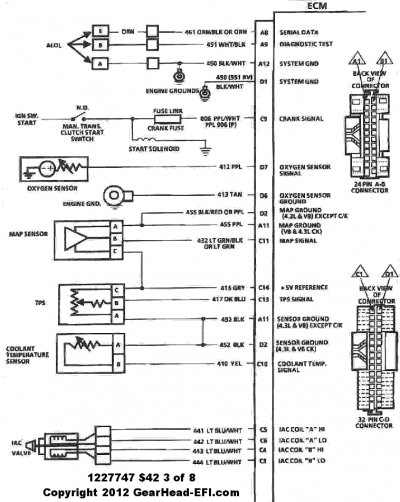

2. Bad throttle position sensor or the wiring is incorrect or faulty. I matched the wiring color for color when installed the new, smaller connector. Maybe that was wrong?

3. Faulty ICM in the distributor, at throttle. Remember, I did the spark test WHILE CRANKING THE ENGINE. NOT with it idling or at throttle.

That's all I can think of right now.

Engine running at idle, at operating temperature.

Dash gauge. Note the oil pressure is at dead 0.

You must be registered for see images attach

My oil pressure gauge, threaded into the side of the block. Note the 11 (almost 12) psi at idle.

You must be registered for see images attach

So, even though it's minimal, it's still acceptable. I'm not worrying about the oil pressure any further at this point.

NOW, for the idle valve adjustment. Some valves definitely were adjusted too tight; taking more than one full turn to start clicking/clacking, and then less than a half turn to quiet down... and then the 1/4 turn preload.

Also, according to the aforementioned video, sometimes the engine will bog down to compensate for the sudden vacuum present in the cylinder. Yup, that happened, too. I wasn't necessarily keeping track of which cylinders or valves presented that result. I was more listening closely trying to hear when the clicking started and stopped.

Either way, there's NO QUESTION now as to the correct adjustment of the valve train.

One other thing I must mention here. Earlier, when I say the engine "starts right up", it took a good few cranks to fire. After this running valve adjustment, the engine DOES start easier. So, that's a plus.

Did it help the engine run correctly at part throttle and/or WOT? Absolutely not. Oh, and I opened the hood and gave it a good rev at idle, attempting to see where the backfiring is coming from. Definitely from the Throttle Body.

So, here's my theories as to why it's doing this.

1. Simply near zero gas in the tank. Runs decent on a level surface until given gas. STALLS when even beginning an incline. Barely starts back up and STRUGGLES to maintain the incline.

2. Bad throttle position sensor or the wiring is incorrect or faulty. I matched the wiring color for color when installed the new, smaller connector. Maybe that was wrong?

3. Faulty ICM in the distributor, at throttle. Remember, I did the spark test WHILE CRANKING THE ENGINE. NOT with it idling or at throttle.

That's all I can think of right now.