How do you get the yellow out of those sockets?I also cleaned 2 out of 4 of the turn signal and parking lamp sockets. What a horrible job.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Laredo

- Thread starter Laredo

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

When are you going to start this thing? I’m in need of some motivation and every time you post lately I think it’s going to be the moment when it all comes together. I just know it’s going to be glorious.

Countless cotton swabs, a microfiber towel, a small pick, a nylon brush, degreaser, and several hours of your time.How do you get the yellow out of those sockets?

I hope to start the engine in 2 months. Transfer case and exhaust system aside, there are still a lot of details to address, such as cleaning electrical terminals/sockets.When are you going to start this thing? I’m in need of some motivation and every time you post lately I think it’s going to be the moment when it all comes together. I just know it’s going to be glorious.

@Laredo can I ask where this clip in circle goes? It is on hose from Purge Canister and routes behind TB and connects to Vapor Canister Purge Valve Switch. Does it appear broken?

You must be registered for see images attach

Yes, the other half is missing. From the factory, the charcoal canister purge line would have been routed above the PCV line. The item circled in the photograph is to secure the purge line to the PCV line.@Laredo can I ask where this clip in circle goes? It is on hose from Purge Canister and routes behind TB and connects to Vapor Canister Purge Valve Switch. Does it appear broken?

You must be registered for see images attach

Ahhh, much better. I can confirm that Dow Corning 4 insulating compound is very easy to use. It also has great reviews, with one reviewer posting a photograph of his Land Cruiser crossing a river and swearing by the product's ability to insulate against water.

Attachments

Last edited:

New wiper cowl (and, not seen, transmission linkages, windshield washer nozzles and 5/32" hose), wiper arms, and wiper blades. All Genuine GM components. Nonetheless, I had to gently bend the passenger side wiper arm to make the blade contact and conform to the windshield. Initially, it was ~1" away from the windshield.

Edit: In case anyone is wondering, I used J-B Weld 31319 Black RTV Silicone Sealant & Adhesive to seal the 4 outer screw holes. It seemed to be an ideal product for this application.

Edit: In case anyone is wondering, I used J-B Weld 31319 Black RTV Silicone Sealant & Adhesive to seal the 4 outer screw holes. It seemed to be an ideal product for this application.

Attachments

Last edited:

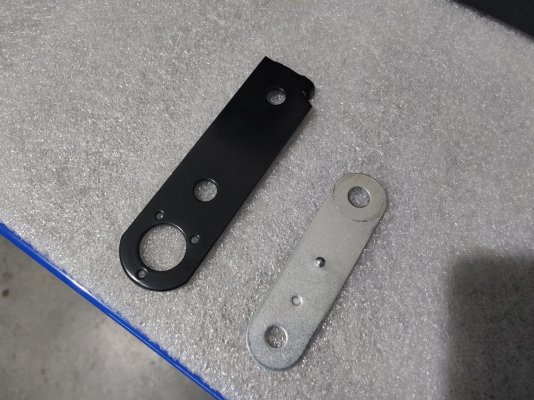

I decided to redo the horn installation. Aside from not having a locating tab, the supplied replacement brackets are shorter and flimsy (they are designed to be bent, if necessary). As the connector is oriented higher on the Genuine GM replacement horns, I quickly discovered the wiring harness will not reach the connector on the front/high note horn. Therefore, I decided drill out the spot welds(?) on the factory horn brackets and find a way to reuse them. Mounting them to the new horns was accomplished using two machine bushings and a fender washer. And because the threaded stud on the horn is quite short, leaving only 0.5 to 1 thread protruding beyond the supplied nut, I was certain to use thread locker (there was minimal threads showing with the supplied replacement bracket as well). I'm much happier with this means of mounting. Moreover, the harness supplying power to the front/high note horn now fits without excessive tension on the harness.

Attachments

Similar threads

- Replies

- 16

- Views

- 1K

- Replies

- 5

- Views

- 909

- Replies

- 4

- Views

- 196

- Replies

- 24

- Views

- 5K

Latest posts

-

-

-

-

-

92 2500 6 lug 4x4 NV4500 built SBC ext cab short box long term build

- Latest: Sean Buick 76

Members online

- 99xcss4

- macrain

- Sean Buick 76

- FLGS400

- Tadow

- IndexOf0

- Kam8

- shaneroze

- hunterkeslar89

- Supercharged111

- Nicks2drtahoe

- Megajeff67

- Komet

- alabbar

- Caman96

- Drunkcanuk

- fancyTBI

- Daly

- alaraine

- JPVortex

- jjester6000

- ToalaBear

- Johnydrew91

- scott2093

- Fish98C2500

- Alteca

- scrilla

- LovesDunes

- Brody

- Zack8

- mason916

- Mpott

- SNCTMPL

- El Vez

- spud

- zampman

- squirrels2k

- jeepguy

- Stumpy

- Olds455

- Ivang4342

- Eeyore79

- splinter

- Jonathen_88

Total: 1,191 (members: 47, guests: 1,144)