I will probably end up doing the conversion, I’m just on a tight budget right now, so I’m gonna hold off for a bit, is there any benefit to the heated o2 besides just keeping it in CL for longer, does it read faster/ more accurate in any way?Don't listen to those who say "you need restriction for blah blah", it's not true. You proved it yourself by opening up your exhaust (through the cutouts), you'll do even better with a less restrictive Y pipe too. It doesn't take much at all to convert to a 3-wire O2 sensor either.

Here's the adapter from Mich Motor Sports - you can find it on Amazon too. It works well with an ACDELCO AFS74. It's simple to install too. The sooner, and longer, you stay in CL the better.

You must be registered for see images attach

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Code 32 with a high flow exhaust.

- Thread starter Nick88

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Not really, it's still an NBO2 (Narrow Band) sensor. It does help you go into CL quicker and stay there during idle, when your exhaust cools off.is there any benefit to the heated o2 besides just keeping it in CL for longer, does it read faster/ more accurate in any way?

If you want to really dial in your AFR throughout the whole range, get a WBO2 (Wide Band).

A NBO2 goes from ~0.1 - 0.95 VDC. (Stoichiometric) is ~.45 VDC. It pretty much just tells you if it's lean or rich. respectively.

The Wide Band O2, like an Innovate LC-2 goes from 0 (7.35 AFR) - 5 VDC (22.39 AFR) so, you can tune it for 14.7 Stoich and ~12.5+/- at WOT for boosted engines and higher for NA). Also for Lean Cruise, I'm running it ~16.7+/- AFR then.

I will probably end up doing the conversion, I’m just on a tight budget right now, so I’m gonna hold off for a bit, is there any benefit to the heated o2 besides just keeping it in CL for longer, does it read faster/ more accurate in any way?

Hello Nick88,

I know what it's like to not have a lot of disposable income, which would help to explain

why I like to gather as much diagnostic confirmation info as possible prior to replacing parts.

You are in luck, for if you take advantage of a little hidden gem that the TBI computers have

onboard where you can use the SES light to tell you in real time if:

* You are in Open Loop or Closed Loop mode.

* If you are in Closed Loop mode, is the O2 sensor reporting lean, stoich, or rich?

The name of the function is "Field Service mode", and it's accessed by shorting

pins A & B together on the ALDL (Assembly Line Data Link) connector under

the dash, followed by starting the engine. (See 1st attachment for FSM specifics.)

Thanks to a fellow forum member, you can actually watch the SES light in

Field Service mode. (Note: This was done accidentally, for he was shorting

the pins in order to retrieve the computer codes while the key was on, engine off,

and then started his truck.)

Here's a link to his video: (SES light indicating Open Loop, Closed Loop, Rich, etc)

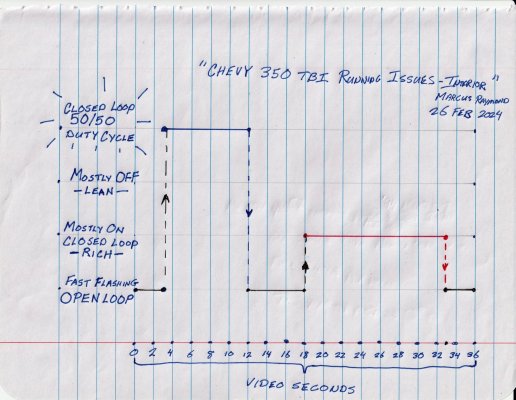

And while you are watching it, you can refer to what I was able to interpret from

the flash patterns. (See 2nd attachment.)

****

To summarize, for zero cost you can find out how long it takes your engine to

go from Open Loop right after startup to Closed Loop. You will also be able to

see how well your O2 sensor is staying in Closed Loop mode while sitting at a

long red light, etc. And with a little practice you should be able to see via the

duty cycle (on time vs off time) just how close your engine bay is running to

stoich vs too rich or too lean.

Let us know if you decide to try the Field Service mode that's embedded in your

TBI computer. And given the mpg you are seeing, I'm going to assume that your

SES light is going to be sharing good news, especially on the parkway.

In other words, you will be able to infer if everything is running normally (in Closed Loop mode)

or if you happen to be in 'Limp Home' mode. (Open Loop on a up to temp engine.)

Best of luck with your hunt for the Code 32 fix.

Cheers --

Attachments

Last edited:

I’ve used the field service mode to track going into closed loop, I know it can be used to read fuel mixture, but I never knew how, so I will be sure to watch that video once I get a chance.Hello Nick88,

I know what it's like to not have a lot of disposable income, which would help to explain

why I like to gather as much diagnostic confirmation info as possible prior to replacing parts.

You are in luck, for if you take advantage of a little hidden gem that the TBI computers have

onboard where you can use the SES light to tell you in real time if:

* You are in Open Loop or Closed Loop mode.

* If you are in Closed Loop mode, is the O2 sensor reporting lean, stoich, or rich?

The name of the function is "Field Service mode", and it's accessed by shorting

pins A & B together on the ALDL (Assembly Line Data Link) connector under

the dash, followed by starting the engine. (See 1st attachment for FSM specifics.)

Thanks to a fellow forum member, you can actually watch the SES light in

Field Service mode. (Note: This was done accidentally, for he was shorting

the pins in order to retrieve the computer codes while the key was on, engine off,

and then started his truck.)

Here's a link to his video: (SES light indicating Open Loop, Closed Loop, Rich, etc)

And while you are watching it, you can refer to what I was able to interpret from

the flash patterns. (See 2nd attachment.)

****

To summarize, for zero cost you can find out how long it takes your engine to

go from Open Loop right after startup to Closed Loop. You will also be able to

see how well your O2 sensor is staying in Closed Loop mode while sitting at a

long red light, etc. And with a little practice you should be able to see via the

duty cycle (on time vs off time) just how close your engine bay is running to

stoich vs too rich or too lean.

Let us know if you decide to try the Field Service mode that's embedded in your

TBI computer. And given the mpg you are seeing, I'm going to assume that your

SES light is going to be sharing good news, especially on the parkway.

In other words, you will be able to infer if everything is running normally (in Closed Loop mode)

or if you happen to be in 'Limp Home' mode. (Open Loop on a up to temp engine.)

Best of luck with your hunt for the Code 32 fix.

Cheers --

I got code 32 again today strangely while accelerating on a parkway ramp after sitting at 55mph for a while (which is why I assume it came on) on a different parkway. I know it runs richer when SES is on because I can smell the exhaust strong in the cab once it comes on while sitting at lights. It will be interesting to use Field service mode to see how much the mixture changes if it comes on again.

On the parkway later and tomorrow I’m going to shut the exhaust cutout and see if the light comes back on. If it does not I will try to open the cutout in increments each day to see how much it can be open before SES comes on. Interesting experiment to post for the forum, in case anyone would need it for any reason.

Once again very very helpful thank you!

I’ve used the field service mode to track going into closed loop, I know it can be used to read fuel mixture, but I never knew how, so I will be sure to watch that video once I get a chance.

It is literally a 36-second video (my hand drawn graph is the video timeline on the x-axis, reported mode on the y-axis.)

Sir, you sound like an *ideal* candidate to put some real-world observations around what it takes to trip a TBI Code 32 vs

staying on just this side of tripping the code. Really cool, solid learning dead ahead. (!) My suggestion would be to

print out that hand-drawn timeline and have it to reference while watching that short video. This should shorten your

learning curve re: the real-time reporting of running rich / stoich / lean by your O2 sensor.

Obviously the FSM doesn't go into a lot of detail, but in the right hands the Field Service mode will give you a good idea of

how well the fine-tuning feedback loop is operating in your engine bay.

I am seriously looking forward to what you discover. And with the price of gas being so volatile (and currently headed in the

wrong direction) anything we can do to eke out a little more (clean) efficiency the better.

Good stuff!

I understand it now fully after seeing the video and your graph. I’m very curious to see later how my motor is running while driving around / on parkway with field service mode. Agreed with the better efficiency with the price of gas. I can also make a post regarding how I have gotten such good gas mileage even with 3.73 gears and 33 inch mud terrains driving around.It is literally a 36-second video (my hand drawn graph is the video timeline on the x-axis, reported mode on the y-axis.)

Sir, you sound like an *ideal* candidate to put some real-world observations around what it takes to trip a TBI Code 32 vs

staying on just this side of tripping the code. Really cool, solid learning dead ahead. (!) My suggestion would be to

print out that hand-drawn timeline and have it to reference while watching that short video. This should shorten your

learning curve re: the real-time reporting of running rich / stoich / lean by your O2 sensor.

Obviously the FSM doesn't go into a lot of detail, but in the right hands the Field Service mode will give you a good idea of

how well the fine-tuning feedback loop is operating in your engine bay.

I am seriously looking forward to what you discover. And with the price of gas being so volatile (and currently headed in the

wrong direction) anything we can do to eke out a little more (clean) efficiency the better.

Good stuff!

AKA Crash Test Dummy!It is literally a 36-second video (my hand drawn graph is the video timeline on the x-axis, reported mode on the y-axis.)

Sir, you sound like an *ideal* candidate to put some real-world observations around what it takes to trip a TBI Code 32 vs

staying on just this side of tripping the code.

Really cool, solid learning dead ahead. (!) My suggestion would be to

print out that hand-drawn timeline and have it to reference while watching that short video. This should shorten your

learning curve re: the real-time reporting of running rich / stoich / lean by your O2 sensor.

Obviously the FSM doesn't go into a lot of detail, but in the right hands the Field Service mode will give you a good idea of

how well the fine-tuning feedback loop is operating in your engine bay.

I am seriously looking forward to what you discover. And with the price of gas being so volatile (and currently headed in the

wrong direction) anything we can do to eke out a little more (clean) efficiency the better.

Good stuff!

AKA Crash Test Dummy!

And if I do all of the above and I can't get this test to pass? In the interest of science I would concoct some sort of

temporary backpressure hack and see if I can figure out just how many inches of exhaust backpressure it takes to

make the light stay out...and then share that info here for the benefit of the other TBI drivers. :0)

Scooterwrench,

It seems that Nick88 is a motivated student of how to improve the efficiency of his rig. When he made the following statement

I thought that this was telling:

On the parkway later and tomorrow I’m going to shut the exhaust cutout and see if the light comes back on. If it does not I will try to open the cutout in increments each day to see how much it can be open before SES comes on. Interesting experiment to post for the forum, in case anyone would need it for any reason.

Of course the ultimate would be if he were to first figure out how much of the exhaust cutout he

can open and still avoid setting the Code 32, and then instrument how much backpressure that equals

using something like this 0-8 psi OTC exhaust system pressure gauge:

You must be registered for see images attach

How cool would it be to know that, say, anything above ~2 psi in the exhaust should pass given the correct negative-backpressure

EGR valve, good O2 sensor, etc. And anything below would be risking popping a Code 32? Right now, I don't think that this

info is available anywhere on the interwebs.

Even without instrumenting the exhaust backpressure Nick88 is going to let us know if the TBI fueling strategy suddenly changes

when his setup trips the Code 32 SES light. (If I had a '95-older TBI GMT400 I would be motivated to connect a dash switch and wire it to

a removable ALDL plug, so that I could enable/disable the Field Service mode from behind the wheel on the fly.)

LOOK at the EGR valve. There's most-likely an "N" stamped into the sheetmetal cover somewhere near the part number.

The EGR valve with an "N" is a negative-backpressure design. It senses backpressure in order to function properly. Change the backpressure radically, and it's not going to work right.

Good call. Item #4 in the FSM's Code 32 test description does mention the usage of a Negative Backpressure EGR valve.

I understand it now fully after seeing the video and your graph. I’m very curious to see later how my motor is running while driving around / on parkway with field service mode. Agreed with the better efficiency with the price of gas. I can also make a post regarding how I have gotten such good gas mileage even with 3.73 gears and 33 inch mud terrains driving around

I would be interested in a post about how you are getting that kind of MPG. I always welcome the opportunity to

compare real-world results, especially on the subject of improving MPG/lowering the cost of enjoying the chore truck.

****

And while looking around at different exhaust backpressure test gauges, I happened across the fact that

there's an actual gauge you can install in the cockpit to let you monitor what your exhaust system is

doing/not doing for you:

You must be registered for see images attach

Given the range (0-60 psi) no doubt this is geared towards the big turbo

installations where the owner knows that it isn't just how high you pressurize

the intake, it's the net difference between the intake and exhaust system

pressures that sets you up for big time power. When you see the exhaust

cutouts behind the turbos then you know that the owner isn't fooling around

with just some whistling underhood bling. :0)

Last edited:

I didn't mean anything derogatory. When I'm testing something I call myself crash test dummy. I think it's a term used more in the biker world.Scooterwrench,

It seems that Nick88 is a motivated student of how to improve the efficiency of his rig. When he made the following statement

I thought that this was telling:

Of course the ultimate would be if he were to first figure out how much of the exhaust cutout he

can open and still avoid setting the Code 32, and then instrument how much backpressure that equals

using something like this 0-8 psi OTC exhaust system pressure gauge:

You must be registered for see images attach

How cool would it be to know that, say, anything above ~2 psi in the exhaust should pass given the correct negative-backpressure

EGR valve, good O2 sensor, etc. And anything below would be risking popping a Code 32? Right now, I don't think that this

info is available anywhere on the interwebs.

Even without instrumenting the exhaust backpressure Nick88 is going to let us know if the TBI fueling strategy suddenly changes

when his setup trips the Code 32 SES light. (If I had a '95-older TBI GMT400 I would be motivated to connect a dash switch and wire it to

a removable ALDL plug, so that I could enable/disable the Field Service mode from behind the wheel on the fly.)

Good call. Item #4 in the FSM's Code 32 test description does mention the usage of a Negative Backpressure EGR valve.

I would be interested in a post about how you are getting that kind of MPG. I always welcome the opportunity to

compare real-world results, especially on the subject of improving MPG/lowering the cost of enjoying the chore truck.

****

And while looking around at different exhaust backpressure test gauges, I happened across the fact that

there's an actual gauge you can install in the cockpit to let you monitor what your exhaust system is

doing/not doing for you:

You must be registered for see images attach

Given the range (0-60 psi) no doubt this is geared towards the big turbo

installations where the owner knows that it isn't just how high you pressurize

the intake, it's the net difference between the intake and exhaust system

pressures that sets you up for big time power. When you see the exhaust

cutouts behind the turbos then you know that the owner isn't fooling around

with just some whistling underhood bling. :0)

Alright guys important update. I used field service mode and driving it was constantly perfect, equal between on and off flashes same duration. The only issue I noticed is after a second of sitting or going extremely slow, even after driving on the parkway, it immediately drops into open loop. Is there any concern with that or is it alright atleast for now to have that happen??

Tomorrow I will shut the cutout and see in the morning if it pops code 32 (Ill try my best to meet the parameters to engage the ecm EGR test) later on in the afternoon I will drive again with the cutout shut in the field service mode and see fuel mixture with higher back pressure and see if it still drops into open loop at stops with more backpressure.

Tomorrow I will shut the cutout and see in the morning if it pops code 32 (Ill try my best to meet the parameters to engage the ecm EGR test) later on in the afternoon I will drive again with the cutout shut in the field service mode and see fuel mixture with higher back pressure and see if it still drops into open loop at stops with more backpressure.

Similar threads

- Replies

- 22

- Views

- 3K

- Replies

- 9

- Views

- 2K

- Replies

- 2

- Views

- 424