You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chasing down cyl. 2 misfire (P0302)

- Thread starter alvaroemg

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

alvaroemg

I'm Awesome

Well…….. compression is almost identical across all cylinders

Well…….. compression is almost identical across all cylinders

That's a good sign. What kind of numbers were you seeing?

alvaroemg

I'm Awesome

I thought all gauges read in psi, unless this is what it means.(lbs per sq. In.)

#1 60, 65, 60lbs/sq./in

#2 75, 70

#3 75, 65, 65

#4 90, 85

#5 70, 60

#6 70, 60, 65

#7 65, 65

#8 75, 70

From the youtube videos i saw, compression should be from 120-150

I received the cap and rotor, wires and 2 more plugs. Still missing 4 plugs.

leak down test still needed? If rings were bad on 4 psi would of dropped to 0 , no?

#1 60, 65, 60lbs/sq./in

#2 75, 70

#3 75, 65, 65

#4 90, 85

#5 70, 60

#6 70, 60, 65

#7 65, 65

#8 75, 70

From the youtube videos i saw, compression should be from 120-150

I received the cap and rotor, wires and 2 more plugs. Still missing 4 plugs.

leak down test still needed? If rings were bad on 4 psi would of dropped to 0 , no?

Did the gauge you used have a face similar to this?

The outer ring is in PSI. (Pounds per Square Inch)

EDIT:

The inner ring is the resulting compression ratio. There are some variables at

play, but what we normally see on a stock motor is 120-150 psi, which translates

to an ~8:1 to 10:1 mechanical compression ratio.The inner ring is for the

metric-centric machines & mechanics.

The readings you have would translate to insufficient compression, which is either a bad

test result or an engine that would barely run? Since you are driving your vehicle,

I'm thinking that we need to rerun the test?

Being able to run a compression test is a valuable skill, but there is a

little 'technique' required to get a reliable reading. Over HERE we were

talking another member through the test process, so instead of typing

it all in twice if you could go check that out and compare it against what

you did, then no doubt we're get this all sorted out.

NOTE: One thing I didn't state in the list of things to do in the other

thread was to make sure and take the reading after 5 compression cycles.

On a healthy cylinder I would expect the readings to climb like this:

1st) 80

2nd) 110

3rd) 125

4th) 133

5th) 140

NOTE: These are made up numbers, but this illustrates how the needle will jump with

every compression event. Important: If the gauge drops backwards after

each compression event, then there's a leak somewhere (schrader valve?) that

you must address before proceeding.

Again, good news that they are all the same and that #4 isn't a dead cylinder.

And once you report back with either repeated or more normal results, then

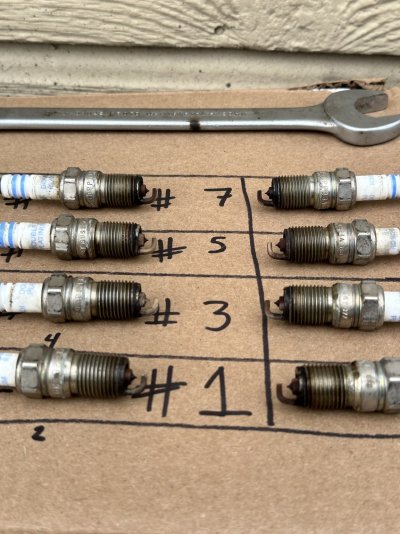

we can discuss the plug coloring that's showing.

Repeating tests can be a bit tedious, but we need trustworthy results in order

to provide the accurate guidance you deserve.

Best of luck --

You must be registered for see images attach

The outer ring is in PSI. (Pounds per Square Inch)

EDIT:

play, but what we normally see on a stock motor is 120-150 psi, which translates

to an ~8:1 to 10:1 mechanical compression ratio

metric-centric machines & mechanics.

The readings you have would translate to insufficient compression, which is either a bad

test result or an engine that would barely run? Since you are driving your vehicle,

I'm thinking that we need to rerun the test?

Being able to run a compression test is a valuable skill, but there is a

little 'technique' required to get a reliable reading. Over HERE we were

talking another member through the test process, so instead of typing

it all in twice if you could go check that out and compare it against what

you did, then no doubt we're get this all sorted out.

NOTE: One thing I didn't state in the list of things to do in the other

thread was to make sure and take the reading after 5 compression cycles.

On a healthy cylinder I would expect the readings to climb like this:

1st) 80

2nd) 110

3rd) 125

4th) 133

5th) 140

NOTE: These are made up numbers, but this illustrates how the needle will jump with

every compression event. Important: If the gauge drops backwards after

each compression event, then there's a leak somewhere (schrader valve?) that

you must address before proceeding.

Again, good news that they are all the same and that #4 isn't a dead cylinder.

And once you report back with either repeated or more normal results, then

we can discuss the plug coloring that's showing.

Repeating tests can be a bit tedious, but we need trustworthy results in order

to provide the accurate guidance you deserve.

Best of luck --

Last edited:

alvaroemg

I'm Awesome

Will re-run compression tests tomorrow. What I noticed once I took out the cap with the wires still attached to it, some wires were longer then others.Did the gauge you used have a face similar to this?

You must be registered for see images attach

The outer ring is in PSI. (Pounds per Square Inch)

The inner ring is the resulting compression ratio. There are some variables at

play, but what we normally see on a stock motor is 120-150 psi, which translates

to an ~8:1 to 10:1 mechanical compression ratio.

The readings you have would translate to a ~5:1 compression, which is either a bad

test result or an engine that would barely run? Since you are driving your vehicle,

I'm thinking that we need to rerun the test?

Being able to run a compression test is a valuable skill, but there is a

little 'technique' required to get a reliable reading. Over HERE we were

talking another member through the test process, so instead of typing

it all in twice if you could go check that out and compare it against what

you did, then no doubt we're get this all sorted out.

NOTE: One thing I didn't state in the list of things to do in the other

thread was to make sure and take the reading after 5 compression cycles.

On a healthy cylinder I would expect the readings to climb like this:

1st) 80

2nd) 110

3rd) 125

4th) 133

5th) 140

NOTE: These are made up numbers, but this illustrates how the needle will jump with

every compression event. Important: If the gauge drops backwards after

each compression event, then there's a leak somewhere (schrader valve?) that

you must address before proceeding.

Again, good news that they are all the same and that #4 isn't a dead cylinder.

And once you report back with either repeated or more normal results, then

we can discuss the plug coloring that's showing.

Repeating tests can be a bit tedious, but we need trustworthy results in order

to provide the accurate guidance you deserve.

Best of luck --

For example: on cyl 3 and 5, wire for 3 was shorter than to 5. I fixed 6 wites all together and than 7 was longer than 5. I fixed some for both sides that were in the wrong spot.

I thought these NgK wires were supposed to have cyl. ID on them, but they didn’t.

I’m routing the wires as we speak with the new cap and rotor already installed.

Btw, wire for cyl 2 had a tear on top and bottom at the base on the cap. Not sure if this contributed to the cyl 2 misfire, here is a picture. Also wire 6.

Attachments

alvaroemg

I'm Awesome

No. Inner ring is pressure measured in Kilopascals (kPa) x 100.Did the gauge you used have a face similar to this?

You must be registered for see images attach

The outer ring is in PSI. (Pounds per Square Inch)

The inner ring is the resulting compression ratio.

For example, 10 x 100 = 1000, 1000 kPa = 145 psi, which is why "10" on the inner ring approximately aligns with "145" on the outer ring.

Has nothing to do with compression ratio.

I agree. "60 psi" is WAY too low to be accurate, unless that engine is REALLY unhealthy, or your elevation is about as high as the Space Station. I watched a 400 "Cleveland" with one cylinder at 50 psi. That cylinder was dead at idle but ran--kind of--at higher power levels.I'm thinking that we need to rerun the test?

Either the compression tester is faulty (very possible) or the process you used was faulty.

"I" would remove the Schrader valve core from the compression tester spark plug hose end to assure it's in good condition (not damaged, or blocked-open with a fleck of rust or carbon) AND is the correct style--it's interchangeable with a tire Schrader valve core, but the tire valve core in a compression tester will produce FALSE low readings--the spring in the tire valve core is too stiff.

The upper Schrader valve could be leaking, but you'd likely hear it.

Yes.Important: If the gauge drops backwards after each compression event, then there's a leak somewhere (schrader valve?) that you must address before proceeding.

Yes.we need trustworthy results in order to provide the accurate guidance you deserve.

Last edited:

Huh.Gauge:

EDIT: Check it out, it's lined up at the 500 Kpascals mark -- says so right on the gauge. Thanks Schurkey!

* Please make sure that your battery is fully charged.

* All plugs out, so that the engine is turning at full speed.

* Pull fuses to ignition coil and fuel pump to disable spark & fuel spray.

* Prop throttle body open so that the cylinder can fill during the intake

stroke instead of just creating a vacuum in the intake manifold.

* Allow each cylinder to cycle through 5 compression strokes, watching

the gauge stair step up to the final value. And of course write it down.

Although I'm not familiar with that particular brand, I'd like you to re-run

the test before we start to suspect the gauge as spreading misinformation.

(And the gauge looks to be in very good/new condition.)

Let's see what you get on the retest. Best of luck!

Last edited:

@roadtrip not bustin ur chops, really  But could you elaborate on the compression ratio comment? I guess I don’t understand how a pressure can dictate a volume

But could you elaborate on the compression ratio comment? I guess I don’t understand how a pressure can dictate a volume

Is it that a kilopascal measurement just so happens to coincide with a compression ratio?

Is it that a kilopascal measurement just so happens to coincide with a compression ratio?

Similar threads

- Replies

- 5

- Views

- 720

- Replies

- 25

- Views

- 1K

- Replies

- 6

- Views

- 1K

- Replies

- 3

- Views

- 382

Members online

- Heinri_k

- Wbruner1

- Supercharged111

- FNolen13

- Cornhub515

- Redline1187

- amrush2112

- someotherguy

- movietvet

- alabbar

- 99xcss4

- Girthbrookz47

- Trio

- Eeyore79

- Laredo

- vince72

- FLGS400

- wespex

- Jackslaw64

- studigggs

- Das Hatt

- 99L31

- Caman96

- Johnboyz71

- KendallConnor

- Condor78

- Aqua-pig

- jealousmuch2010

- Alteca

- frederik

- Ryanstokes8

- spoisel

- HiItsRem

- Catfish18

- L31MaxExpress

- El Tigre

- hutcholdschool

- shamusshanahan

- Knucklehead808

- caliburito

- jbphelps76

- 0xDEADBEEF

- Drunkcanuk

- jrodsavvy

- Joe Dirte

- 454cid

- Andersonandsons1982

- Parking lot mechanic

- Moofus02

- David Hazel

Total: 1,665 (members: 68, guests: 1,597)