Hello, I have an issue with my 1997 Chevy Suburban with 5.7 Vortec and dual fuel conversion, 215k kilometers: it developed a consistent rough idle since a few days that started when driving in very rainy weather, but it does only do this when running on LPG, not on gasoline. On gasoline it runs very smooth. Hot or cold makes no difference. Any idea where I could start with the troubleshooting? I also hear a very distinctive tick once every revolution when it is idling rough, sounds a bit like a noisy valve. But when on gasoline there is no noise. Any thoughts on where to start? Thanks!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1997 Chevy Suburb 5.7 K1500 rough idle

- Thread starter Fredje

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Hello, I have an issue with my 1997 Chevy Suburban with 5.7 Vortec and dual fuel conversion, 215k kilometers: it developed a consistent rough idle since a few days that started when driving in very rainy weather, but it does only do this when running on LPG, not on gasoline. On gasoline it runs very smooth. Hot or cold makes no difference. Any idea where I could start with the troubleshooting? I also hear a very distinctive tick once every revolution when it is idling rough, sounds a bit like a noisy valve. But when on gasoline there is no noise. Any thoughts on where to start? Thanks!

Greetings Fredje and welcome to the GMT400 forum!

By coincidence I've been down in a deep Vortec distributor rabbit hole trying to get

a better understanding of precisely how the performance of these units can deteriorate

and we end up with intermittent misfires with no Check Engine Light, P0300-P0308 codes

with a light, or a CEL with a P1345 code.

You have a very interesting problem description in that you have a somewhat rare dual-fuel

setup, and the problem presents when running on LPG but not gasoline. Disciplined troubleshooting would have

us focus on how the use of one fuel 'stresses' the ignition system differently than the other fuel.

Which, at first glance, sounds either impossible or highly improbable, since the distributor is located on the back

of the engine working with electrical arc distribution, and isn't inside the combustion chamber where the different fuels

are actually burning?

****

According to the following youtube video, one major difference between running on gasoline vs LPG is that

there is much more timing (spark advance) involved when the engine is running on LPG. This additional spark

advance leads directly to an appreciably larger gap that much be traversed between the spinning rotor firing tip

versus the stationary spark plug wire terminal inside the distributor cap. Please observe closely as the owner

of a clear distributor cap-equipped dual-fuel Vortec motor gives us a good view of what's going on:

xc_hide_links_from_guests_guests_error_hide_media

I find this really interesting, and it actually makes sense that they would aggressively turn up the spark advance

on the LPG, mimicking a higher compression engine on the fly by doing so. (Here in the states Honda has been

selling a Honda Civic GX, featuring a single-fuel CNG engine that's running a 12.5:1 compression ratio. HIGH COMPRESSION Civic GX link)

As for the misfire showing up after very heavy rainy weather, all distributor caps find this weather extra challenging,

and quite possibly internal aging combined with the extra humidity has uncovered an internal weakness allowing

misfire under stress? New cap & rotor or not, the symptoms warrant a 'close' inspection of the inside of the

distributor cap and rotor. (Sometimes the sparks blow through the rotor to the inviting ground presented by

the distributor shaft it's bolted to.)

Lastly, the 'once per revolution noise'? First of all, we have to keep in mind that the distributor actually spins at

1/2 of the engine rpm. (360° of spark distribution occurs over 720° of crank rotation.)

So if you can prove it's once every engine revolution we would either have to declare that there's excess play

in the distributor bushings allowing interference between spinning rotor firing tip and the stationary spark plug

wire terminals twice per rotation, *or* expand the search for the noise to other parts of the engine where a

'once per revolution' noise could be generated.

But let's say that what sounds to the ear is 'once per revolution' is emanating from the dizzy itself. As in once

per dizzy revolution? Assuming you have an old inductive clamp-on timing light lying about, you can try to

move the clamp around the 8 spark plug wires and see if you can't get the noise & light flash to sync up,

thereby showing you which cylinder is associated with this noise? For example, unbeknownst to you the

PO (Previous Owner) broke one of the distributor cap mounting screws off, the cap is now at a slight angle,

and the spinning rotor tip is hitting the #4 terminal as it goes by? (Note: This works best on a slow idle, not at

speed. But it does work. Also works to help identify a single noisy lifter. [with a little math to account for the

offset in intake or exhaust valve opening vs. TDC...but I digress.] ) (OLD inductive timing light link)

****

This is starting to turn out to be a term paper, so I'll wrap this up here. Thanks to your detailed problem

description & unique dual-fuel setup, if I were you I would look carefully at the condition of your distributor

cap & rotor, and replace them at any sign of wear/weakness/failure. Make sure that your distributor doesn't

have excess slop/play -- they are known to develop bushing wear when a lot of miles have accumulated.

And if the spark plugs are old soldiers, then the amount of Kilovolts requred to jump the worn gaps goes up,

further stressing an already stressed situation. BTW, you don't need fancy plugs, a set of non-exotic metal

NGK plugs with the V-groove have worked well for me over the years.

So give all of the above some thought, look for the worn out parts and replace them, and by all means if you

have any further questions -or- fix the problem, please come back here and share the answer for the 3 other

dual-fuel owners out there.

Happy Hunting!

Cheers --

Last edited:

HotWheelsBurban

Gotta have 4 doors..... Rawhide, TOTY 2023!

This may be another situation that could be helped by replacing the cap and rotor with the UMP vented cap and rotor. They have brass contacts and are made of better quality plastic than the stock ones. And the vent in the cap allows humidity to escape, so it can't affect the firing process.

I live in Houston, Texas, USA and it's very humid here most of the year. I had problems with the cap and rotor getting moisture inside them, on my Suburban, several times I had to get under the hood and climb back to the distributor and clean the cap and rotor off. After I replaced the cap with the UMP cap, I have not had to do this again. When I got my crew cab, it had a rough idle; that truck had been sitting a lot because the previous owners hadn't driven it much. One of the upgrades I did to it was the UMP cap and rotor, along with a new set of spark plugs. These helped tremendously, and a new fuel filter helped too. The problem is almost gone; replacing the spark plug wires will probably finish it off.

I live in Houston, Texas, USA and it's very humid here most of the year. I had problems with the cap and rotor getting moisture inside them, on my Suburban, several times I had to get under the hood and climb back to the distributor and clean the cap and rotor off. After I replaced the cap with the UMP cap, I have not had to do this again. When I got my crew cab, it had a rough idle; that truck had been sitting a lot because the previous owners hadn't driven it much. One of the upgrades I did to it was the UMP cap and rotor, along with a new set of spark plugs. These helped tremendously, and a new fuel filter helped too. The problem is almost gone; replacing the spark plug wires will probably finish it off.

Dear enthousiast, many thanks for the elaborate reply. I love this car, but with a forum like this I might love it even more!

To answer your questions, and to give an update to my findings some extra details:

- it did not throw a code - yet

- Since it does not do it on gasoline, but it does on LPG, I checked the ignition system, and while the distributor was replaced very recently I think I am going to assume there is spark. I wanted to pull the plugs, but I do not have spares yet, and given their awkward position and me not having an impact wrench, I left them as is and did some troubleshooting by disconnecting the plug cables (does it run better or worse when pulling this or this plug connector...), to find that it did not make any difference when I pulled plug on cylinder 4 on bank 1, but with gasoline it started skipping on that leg, with LPG it did not make any difference. So I do have spark on cylinder no 4, but apparently as removing the plug connector does not make a difference on LPG and keeps on running the same (bad) I suspect this cylinder not firing.

- The ticking is very noticeable and should have something to do with it.

So I decided to check why cylinder number 4 on bank 1 was not having a combustion.

When unplugging the LPG injectors (4 on each side), and idling on LPG, the one on cylinder number 4B1 did not make a difference. That was to be expected as I concluded that there was no combustion taking place. But the strange thing was that the ticking completely disappeared. So the ticking is probably coming from the injector itself.

One thing I can do is switch injectors tubing 3 and 4, and their corresponding connectors as not to mess up the injection timing, however working on LPG is new for me so I am extra cautious. If all reacts the same and the rough idling does not change when removing the spark plug wire, then I should replace that injector.

I will thinker a bit if I should replace the injector myself or ask it to my LPG/dual fuel specialist...

But I think I have found the issue, which makes me kinda happy.

Any other things I should consider checking while I feel like it?

Many many thanks!

I will keep you posted on the progress!

PS: many thanks for that vid, I did not know that! However I thought that the timing for the spark was determined by the distributor?

PS2: I'll take some pictures of the setup

To answer your questions, and to give an update to my findings some extra details:

- it did not throw a code - yet

- Since it does not do it on gasoline, but it does on LPG, I checked the ignition system, and while the distributor was replaced very recently I think I am going to assume there is spark. I wanted to pull the plugs, but I do not have spares yet, and given their awkward position and me not having an impact wrench, I left them as is and did some troubleshooting by disconnecting the plug cables (does it run better or worse when pulling this or this plug connector...), to find that it did not make any difference when I pulled plug on cylinder 4 on bank 1, but with gasoline it started skipping on that leg, with LPG it did not make any difference. So I do have spark on cylinder no 4, but apparently as removing the plug connector does not make a difference on LPG and keeps on running the same (bad) I suspect this cylinder not firing.

- The ticking is very noticeable and should have something to do with it.

So I decided to check why cylinder number 4 on bank 1 was not having a combustion.

When unplugging the LPG injectors (4 on each side), and idling on LPG, the one on cylinder number 4B1 did not make a difference. That was to be expected as I concluded that there was no combustion taking place. But the strange thing was that the ticking completely disappeared. So the ticking is probably coming from the injector itself.

One thing I can do is switch injectors tubing 3 and 4, and their corresponding connectors as not to mess up the injection timing, however working on LPG is new for me so I am extra cautious. If all reacts the same and the rough idling does not change when removing the spark plug wire, then I should replace that injector.

I will thinker a bit if I should replace the injector myself or ask it to my LPG/dual fuel specialist...

But I think I have found the issue, which makes me kinda happy.

Any other things I should consider checking while I feel like it?

Many many thanks!

I will keep you posted on the progress!

You must be registered for see images attach

PS: many thanks for that vid, I did not know that! However I thought that the timing for the spark was determined by the distributor?

PS2: I'll take some pictures of the setup

Last edited:

Dear enthousiast, many thanks for the elaborate reply. I love this car, but with a forum like this I might love it even more!

To answer your questions, and to give an update to my findings some extra details:

- it did not throw a code - yet

- Since it does not do it on gasoline, but it does on LPG, I checked the ignition system, and while the distributor was replaced very recently I think I am going to assume there is spark. I wanted to pull the plugs, but I do not have spares yet, and given their awkward position and me not having an impact wrench, I left them as is and did some troubleshooting by disconnecting the plug cables (does it run better or worse when pulling this or this plug connector...), to find that it did not make any difference when I pulled plug on cylinder 4 on bank 1, but with gasoline it started skipping on that leg, with LPG it did not make any difference. So I do have spark on cylinder no 4, but apparently as removing the plug connector does not make a difference on LPG and keeps on running the same (bad) I suspect this cylinder not firing.

- The ticking is very noticeable and should have something to do with it.

So I decided to check why cylinder number 4 on bank 1 was not having a combustion.

When unplugging the LPG injectors (4 on each side), and idling on LPG, the one on cylinder number 4B1 did not make a difference. That was to be expected as I concluded that there was no combustion taking place. But the strange thing was that the ticking completely disappeared. So the ticking is probably coming from the injector itself.

One thing I can do is switch injectors tubing 3 and 4, and their corresponding connectors as not to mess up the injection timing, however working on LPG is new for me so I am extra cautious. If all reacts the same and the rough idling does not change when removing the spark plug wire, then I should replace that injector.

I will thinker a bit if I should replace the injector myself or ask it to my LPG/dual fuel specialist...

But I think I have found the issue, which makes me kinda happy.

Any other things I should consider checking while I feel like it?

Many many thanks!

I will keep you posted on the progress!

You must be registered for see images attach

PS: many thanks for that vid, I did not know that! However I thought that the timing for the spark was determined by the distributor?

PS2: I'll take some pictures of the setup

Hello Fredje,

Glad to hear that you were able to make positive progress on troubleshooting the miss, and

even better, being able to correlate the misfire to the new noise. (By the way, I take it that

your dual-fuel system is aftermarket & not an option from GM?) If so, could you reply with a

link to their website so that I can read up on it? It looks interesting!

Speaking of which, I am not familiar with the layout of your LPG fuel delivery setup, but if you

can physically get to the injectors while the engine is running, then if you have a mechanic's

stethoscope you will really be able to hear the difference between a good vs faulty injector.

You must be registered for see images attach

And if you don't already have on, consider getting one. They are affordable and well worth

having if/when you need to precisely locate a new noise in the engine bay.

****

Another thought I had reading your reply is that there are few things that can give you a

better Ignition symptom than a problem over with the fuel delivery system. And vice-versa.

I know I've worked hard to fix fuel systems I suspected, only to discover that it was an ignition

problem all along. (For a long time I have believed that engines enjoy feeding me my fair share

of Humble Pie.) Whether it's the Fuel or Ignition system, I've found it takes a long time to

fix something that isn't broken.

Finally, in the pre-ECU days the distributor *did* set the spark timing, first with the base (initial) timing

set via twisting the distributor to the desired spot, + a mechanical centrifugal advance (for rpm)

+ a vacuum advance canister. (for load)

Once GM switched to the ECU (name changed to VCM starting in '96) now the spark timing is

calculated by the computer, sends a trigger to the ICM, (Ignition Control Module) which in turn

drives the Coil, which sends the high voltage pulses (sparks) to the center of the distributor cap,

and the rotor delivers the right spark to the right spark plug wire terminal...assuming the last

human who worked on it got the CMP retard set to 0°. Although the distributor still delivers

the sparks, it's now just a dumb distribution system.

In other words, all the mechanical calculating has been removed from the distributor and given

to the computer in order to improve the spark timing accuracy.

****

Nice to make your acquaintance, and it's cool to add another international GMT400 enthusiast

to the forum. Let us know what the final solution turns out to be.

Cheers --

Last edited:

1. Cylinder 4, Bank 1: Chevy numbered their cylinders differently--you're talking about Cylinder 7.

Bank 1 (left side as seen from the driver's seat) is "odd", 1, 3, 5, 7. One at the front, seven at the rear. Bank 1 is half-an-inch farther forward than Bank 2.

Bank 2 (right side as seen from the driver's seat) is 2, 4, 6, 8. Two at the front, eight at the rear.

2. Vortec distributor caps are infamous for failure. This seems like a dual-failure issue--you have a dead cylinder on CNG, you have a weak, misfiring cylinder on gasoline. I suspect BOTH the CNG delivery for #7, AND a weak ignition (cap, rotor, plug wires, or spark plug) for #7 that functions less-than-optimum on gasoline.

Bank 1 (left side as seen from the driver's seat) is "odd", 1, 3, 5, 7. One at the front, seven at the rear. Bank 1 is half-an-inch farther forward than Bank 2.

Bank 2 (right side as seen from the driver's seat) is 2, 4, 6, 8. Two at the front, eight at the rear.

2. Vortec distributor caps are infamous for failure. This seems like a dual-failure issue--you have a dead cylinder on CNG, you have a weak, misfiring cylinder on gasoline. I suspect BOTH the CNG delivery for #7, AND a weak ignition (cap, rotor, plug wires, or spark plug) for #7 that functions less-than-optimum on gasoline.

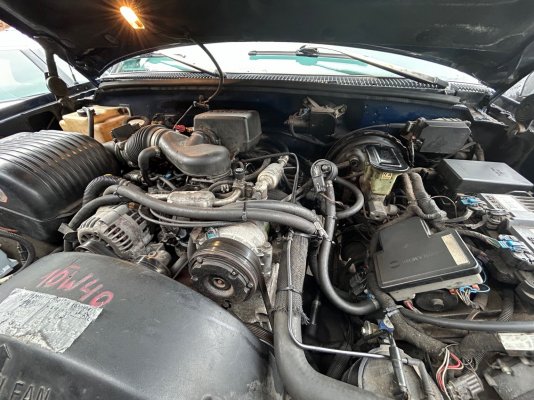

Thanks for the clarification on the cylinder numbers. That would mean I was talking about cylinder number 7. We recently replaced the entire distributor so my first guess is that wouldn't be the issue, but you're right and I will dig deeper into the issue this weekend questioning the LPG system as well as the ignition system. As promised I post some pictures of the setup. It's a Prins VSI (Vapour Sequential Injection) system that was installed by the previous owner, and has always run very good, at least as good as with regular gasoline. It is indeed an aftermarket system from a dutch manufacturer with very good reputation, and they're still in business: https://www.prinsautogas.com/en/systems/vsi-system

I will keep you all posted on the progress.

I will keep you all posted on the progress.

Attachments

Last edited:

Update: last weekend I ordered a new injector rail (4 injectors), wet and dry gas filters and went ahead today. Apart from some freightening moments (remaining gas escaping when loosening the tubing and filters) I managed to replace the defective items. All went well, no leaks after assembly, and the burb is running as new again. It cost me around 500Euro for all the parts, bud glad I could install them myself.

Now, I would like to keep the replaced injectors as spares in case of, but I still need to inspect them on why 1 injector failed. Cleaning can do wonders, but how should I clean the injector assy? Ultrasonic? Or just some brake fluid / carb cleaner? Thanks a lot!

Now, I would like to keep the replaced injectors as spares in case of, but I still need to inspect them on why 1 injector failed. Cleaning can do wonders, but how should I clean the injector assy? Ultrasonic? Or just some brake fluid / carb cleaner? Thanks a lot!

Similar threads

- Replies

- 2

- Views

- 3K

- Replies

- 2

- Views

- 217

- Replies

- 7

- Views

- 906