Wow that was quit a bit of info. Took a few times but I think I got it. So here's the latest. YES same scanner as day 1 and same oem parts. Only thing changed was the upper intake removed and installed for a lifter inspection/adjustment.

Truck was at the shop because it wasn't running nor idling when I got done. Family member with a automotive shop took in the truck and found it was a faulty map sensor. Upon testing and retracing My steps they looked and tested all over the engine. Meaning valves,rods, pistons, compression and electrical signal. He and another veteran mechanic checked signal from cam and crank using some fancy machine that checks wave length. According to them everything checked out.

When they removed the distributor they lined up the pins and inspected the position of the rotor.

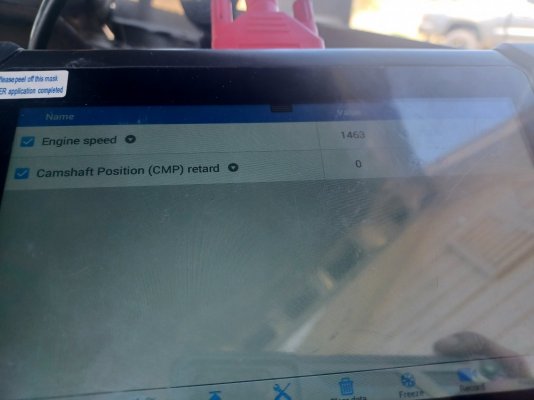

Fast forward a few days best they could do was -7. They used a different bidirectional scanner but got the same reading as my original scanner.

There conclusion is the timing chain could be stretched.

* -7 degrees after intake manifold removed and replaced. (Hint: Think about how vertical height of dizzy affects rotor{shaft} position.)

Now in my case. No I did not mark before and after the distributor was removed. Just like the -1 degree was from a few months ago.

...But I figured a timing chain shouldn't stretch between 4 or so months of regular driving and not towing...

Yes I do like to speed but even then we're talking what 5 degrees to get it to spec?

* " -1 degree was from a few months ago."

I agree. I'm not by any means having second thoughts. I'm just trying to understand what changed or worn to make the truck read -7.

...As long as it reads 0 I'm happy. Just like, as long as there's no squeaks, pings, ticks, and popping lol.

...I guess I'm more or less worried about what the veterans/friends told me being stretched chain, sprocket worn, loose bolt or bolts allowing something to tweak since the motor new.

* again, the -7 reading was made after the intake manifold was removed and reinstalled. (Round 2)

I can assure you from day 1 the cap was against the plenum to read 0. After several months it read -1 without anybody touching it. I couldn't adjust it more because it was maxed out.

* I think this is the true and total CMP 'Cam Retard' signal drift due to the timing chain. From 0 to -1 degree.

****

@SUBURBAN5, you had me wondering about where did the the extra 6 degrees of CMP <> CKP skew come from?

Was it chain wear? Instead of declaring victory over achieving the zero reading and forgetting this detail, we must

account for this discrepancy before we go before the Impound Board. :0)

Seriously, I think I have the answer. In chronological order:

1) When you originally installed your 383, you were able to just get the -0- reading by forcing the dizzy up against

the manifold. Maybe not a perfect visual match for the engines that came off the GM assembly line...but it worked.

2) Months later you rechecked and it was -1 degree. Makes sense given normal break-in, still in spec, not a problem.

3) Now you change the intake manifold gasket. Now I'm inferring a bit here, since there was no before vs after intake

manifold height measurement made, but I *do* know that as I raise or lower the distributor, due to the curvature in

the cut of the gears, the distributor shaft (and rotor tip, and the CMP sensor setup) is affected by the up and down movement.

I don't know for sure if the intake manifold distributor mounting surface ended up higher -or- lower the 2nd time around

versus the 'months ago' 1st time around, but there was a change. And *that change* is what caused the -1 degree reading

to move an additional 6 degrees away from what it was. (!)

Your timing chain is *not* stretched several degrees. Maybe a degree total since original installation, so now that we've

accounted for where the additional timing skew came from, now you can relax and enjoy that 383 a little bit more. :0)

And as troubleshooters we have incontrovertible proof that there is a vertical component to the Vortec-specific CMP Retard signal.

No doubt there's a Mechanical Engineering guru out there somewhere who can translate every .001" of elevation change into

another fraction of a degree of difference in the CMP Retard signal. And if the difference is great enough, then you may

be forced to flip a 13-tooth dizzy gear in order to give you the needed dizzy clocking/swing room to dial in your Vortec dizzy

without having to jam it against the intake in order to get it as close as possible.

Summary:

I think that your dizzy gear was 180 out when you first put this engine together. However, due to the way that the tolerances

stacked up, by rotating your dizzy hard against the manifold you managed to get your CMP Retard adjustment to just come in.

When you went in to replace the intake manifold gasket (Round 2) the way the assembly tolerances stacked up you now had a

head-scratching 6 additional degrees of timing skew? WTF?

****

Dude, I've love to be a fly on the wall when you lay all this out to the guys in the garage that helped find the bad MAP sensor

and then were puzzling over this adjustment. They won't believe it. Good thing you took photos.

And again, thanks for cheerfully seeing this whole thing across the finish line. By doing so, you have cleared up the worry

about a bad timing chain. And thanks to the fact that you had proof of the original vs new Cam Retard readings, we were

able to infer to a high degree of confidence that there's a vertical component to where the distributor housing versus the

rotor tip ends up. (Not to mention that pesky CMP <> CKP 'Cam Retard' timing skew measurement.)

Good stuff. One of the reasons that folks participate in these forums is to gain valuable insight into all the hints & kinks

in our GMT400s and their powerplants. I know I feel like I'm leaving with more than what I came with at the start of your

CMP-a-thon. :0)

Cheers --